Silicon carbide lightning protection material and preparation method thereof

A lightning protection, silicon carbide technology, applied in protective equipment, chemical instruments and methods, protective clothing, etc., can solve problems such as inability to meet, protection function failure, thermal damage, etc., and achieve the effect of improving lightning protection performance and thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

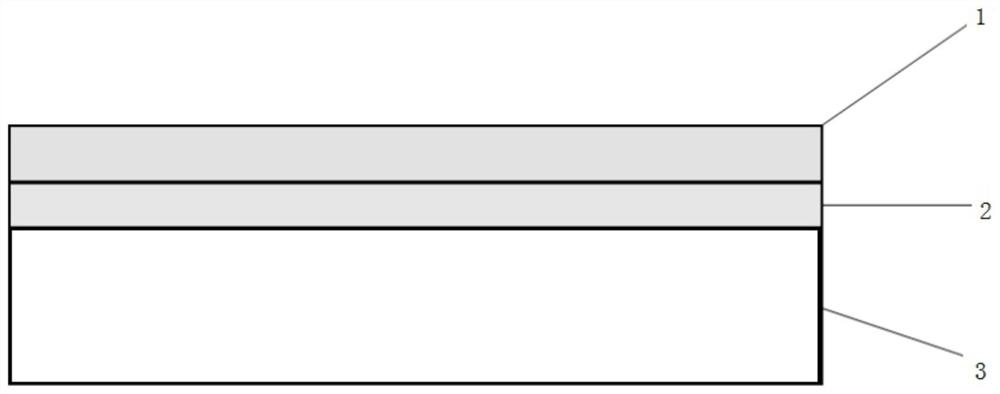

Image

Examples

specific Embodiment approach 1

[0024] A preparation method of silicon carbide lightning protection material, comprising the steps of:

[0025] Step 1. Weigh 5 parts of silicon carbide and 95 parts of epoxy resin according to the parts by weight, add the weighed silicon carbide into the weighed epoxy resin under the condition of mechanical stirring, and stir at room temperature 10h, obtain silicon carbide epoxy resin solution, stand-by;

[0026] Step 2. Dip the carbon fiber into the epoxy resin solution to obtain the carbon fiber reinforced resin prepreg, and then use the hand lay-up method to lay the carbon fiber reinforced resin prepreg according to the cycle angles of 0°, 45°, 90°, -45°, and 0° A carbon fiber reinforced resin prepreg plate with a thickness of 2mm is ready for use;

[0027] Step 3. Take the extended metal mesh and immerse it in the silicon carbide epoxy resin solution obtained in step 1. Take it out and lay it on the carbon fiber reinforced resin prepreg plate prepared in step 2. Carry ou...

specific Embodiment approach 2

[0038] A preparation method of silicon carbide lightning protection material, comprising the steps of:

[0039] Step 1. Weigh 25 parts of silicon carbide and 75 parts of epoxy resin according to the parts by weight, add the weighed silicon carbide into the weighed epoxy resin under the condition of mechanical stirring, and stir at room temperature 12h, obtain silicon carbide epoxy resin solution, stand-by;

[0040] Step 2. Dip the carbon fiber into the epoxy resin solution to obtain the carbon fiber reinforced resin prepreg, and then use the hand lay-up method to lay the carbon fiber reinforced resin prepreg according to the cycle angles of 0°, 45°, 90°, -45°, and 0° A carbon fiber reinforced resin prepreg plate with a thickness of 1-4mm is ready for use;

[0041] Step 3. Take the extended metal mesh and immerse it in the silicon carbide epoxy resin solution obtained in step 1. Take it out and lay it on the carbon fiber reinforced resin prepreg plate prepared in step 2. Carry...

specific Embodiment approach 3

[0052] A preparation method of silicon carbide lightning protection material, comprising the steps of:

[0053] Step 1. Weigh 10 parts of silicon carbide and 90 parts of epoxy resin according to the parts by weight, add the weighed silicon carbide into the weighed epoxy resin under the condition of mechanical stirring, and stir at room temperature 12h, obtain silicon carbide epoxy resin solution, stand-by;

[0054] Step 2. Dip the carbon fiber into the epoxy resin solution to obtain the carbon fiber reinforced resin prepreg, and then use the hand lay-up method to lay the carbon fiber reinforced resin prepreg according to the cycle angles of 0°, 45°, 90°, -45°, and 0° A carbon fiber reinforced resin prepreg plate with a thickness of 1-4mm is ready for use;

[0055] Step 3. Take the extended metal mesh and immerse it in the silicon carbide epoxy resin solution obtained in step 1. Take it out and lay it on the carbon fiber reinforced resin prepreg plate prepared in step 2. Carry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com