Soft packing lithium battery packaging and supporting robot

A technology of soft-pack lithium batteries and robots, applied in transportation and packaging, battery components, circuits, etc., can solve problems such as explosion, high labor intensity, waste of human resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

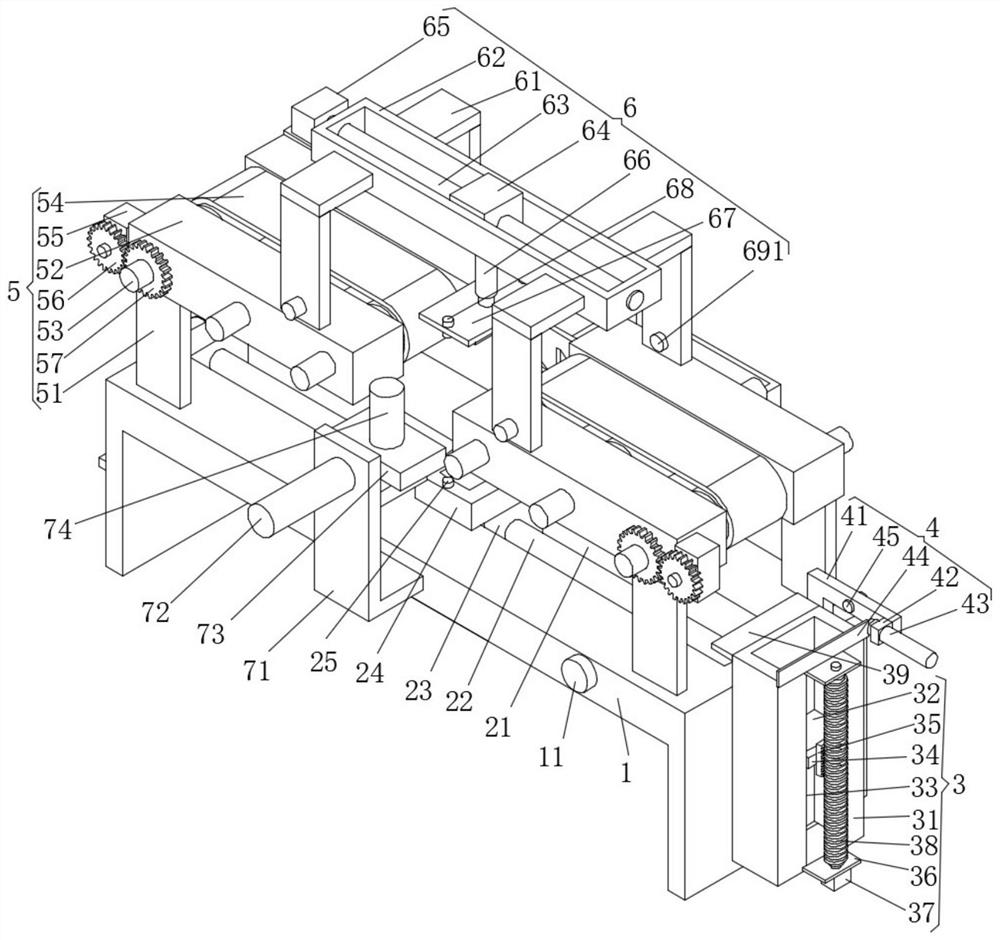

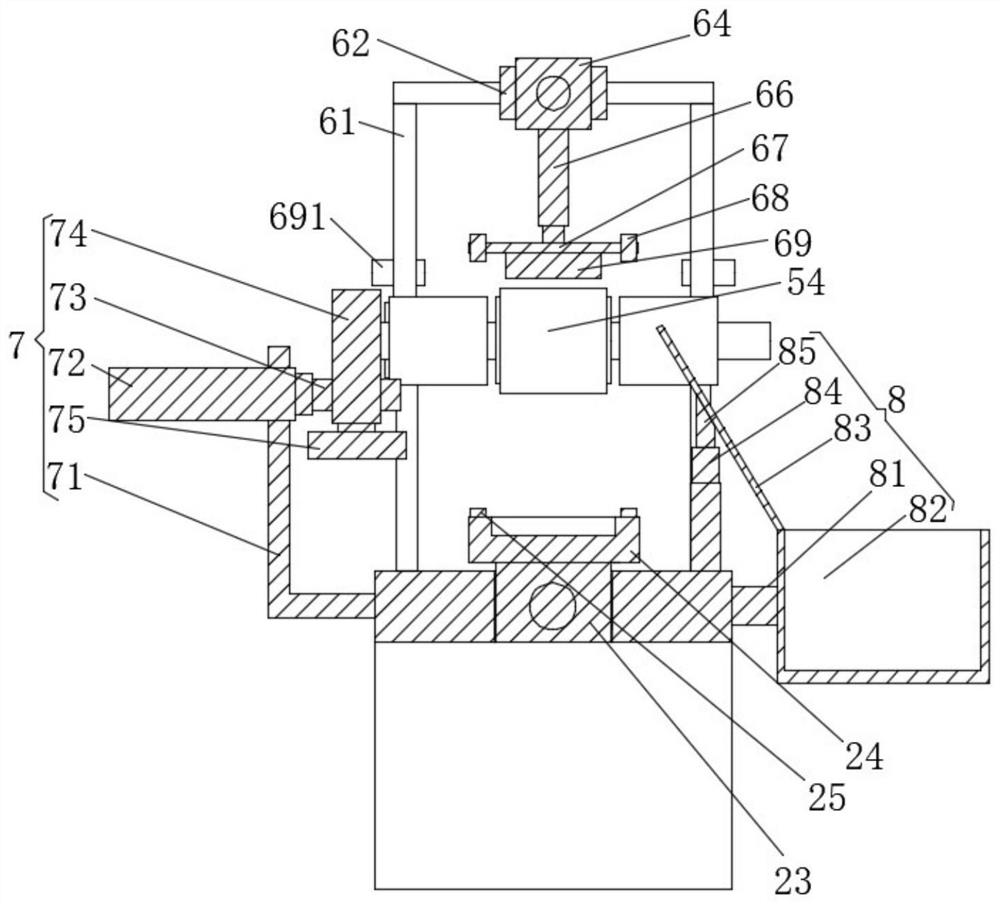

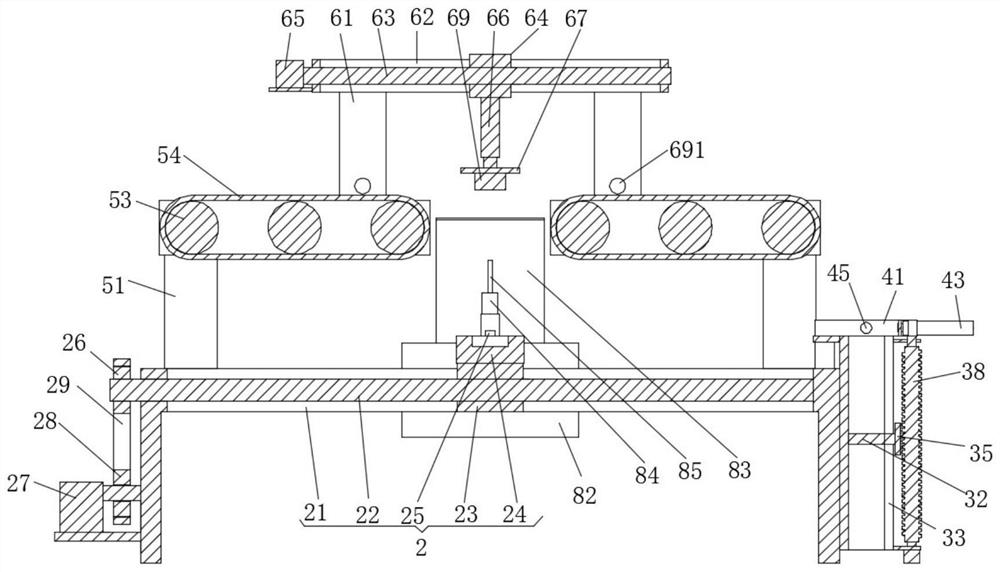

[0028] See Figure 1-4 The present invention provides a technical solution: a soft boosted lithium battery package support robot, including stations 1, transfer assembly 2, and sheet assembly 3;

[0029] Stem 1: The upper surface side is provided with a push assembly 4, and the push assembly 4 includes a bracket 41, a mounting plate 42, a first electric push rod 43, a push plate 44, and a first ranging sensor 45, and a bracket 41 is located. On the surface side of the stage 1, the mounting plate 42 is provided at one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com