Foaming ceramic heat preservation and decoration external wall panel integrated structure and technology and application thereof

A technology of foamed ceramic plates and foamed ceramics, which is applied in the directions of thermal insulation, walls, building components, etc., to reduce the cost, expand the scope of use, and save social resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

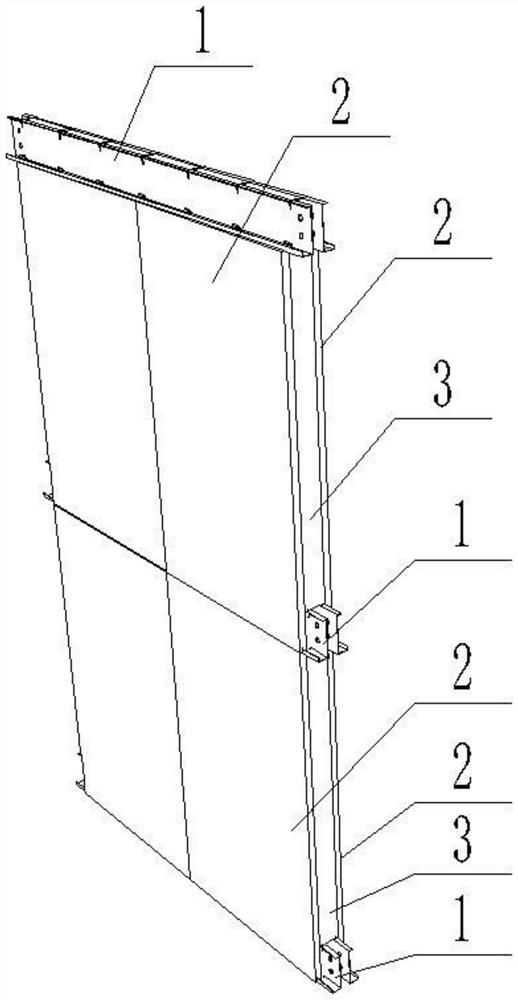

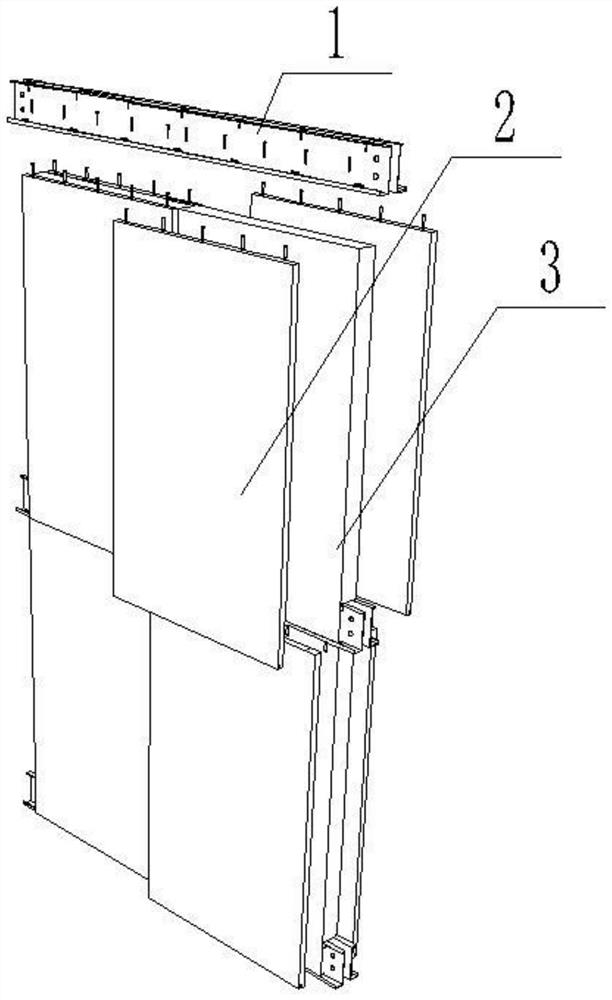

[0031] Such as Figure 1 ~ 13 As shown, the present invention is an integrated structure of a foaming ceramic insulation ornament, including a diaphragm-based composite member 1, a foamed ceramic plate 2, and an insulation plate 3, and a plurality of the character combination member 1 is vertical. The direction is spaced apart, and there is a foaming ceramic plate 2 and an insulation board 3 between adjacent one-character combination members 1, each of which is foaming on both sides of each of the several-character combination members 1. Ceramic plate 2, two foaming ceramic plates 2 are provided with an insulation plate 3;

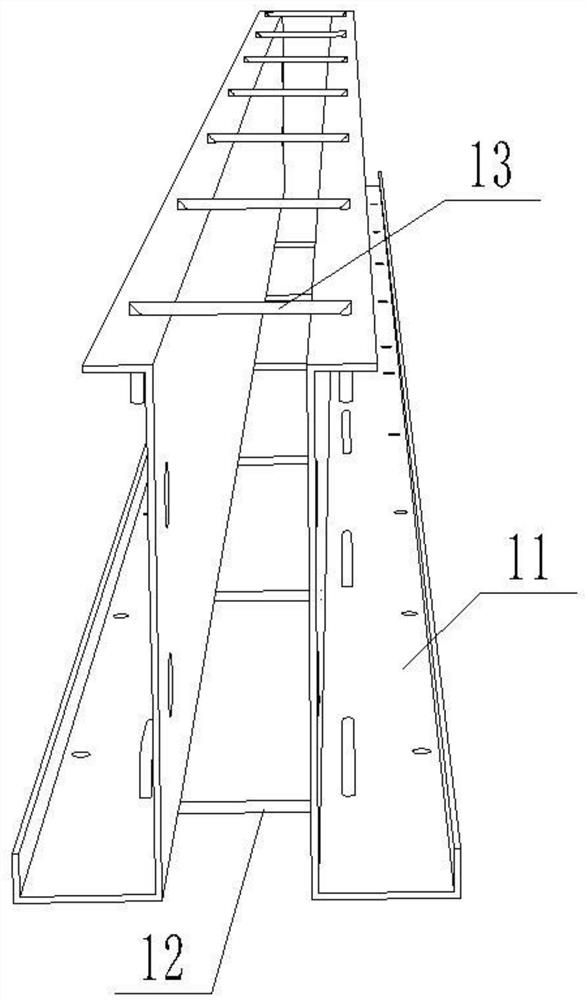

[0032] The sequence-type combination member 1 includes a J-shaped member 11, the M connecting member 12, and the U-shaped connector 13, and the two J-shaped members 11 are backwarded, and there is a certain gap between the two, two The lower end of the J-shaped member 11 is joined together by the M connector 12, and the upper end of the two J-shaped members 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com