Terahertz microfluidic sensor with metal square resonance array

A terahertz and sensor technology, applied in the field of terahertz microfluidic sensors, can solve the problems of high Q value and high sensitivity that cannot meet actual needs, and achieve the effect of improving Q value and detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

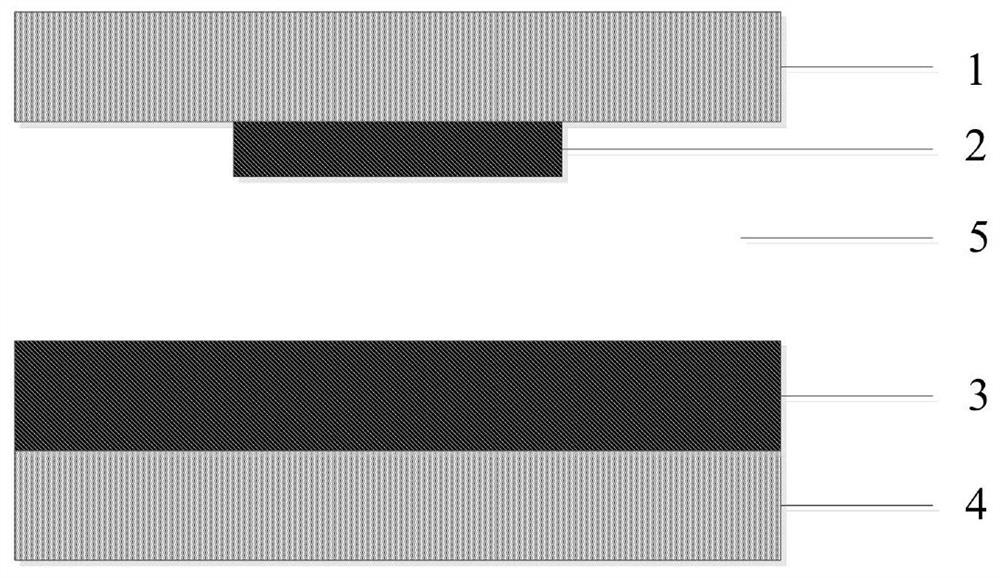

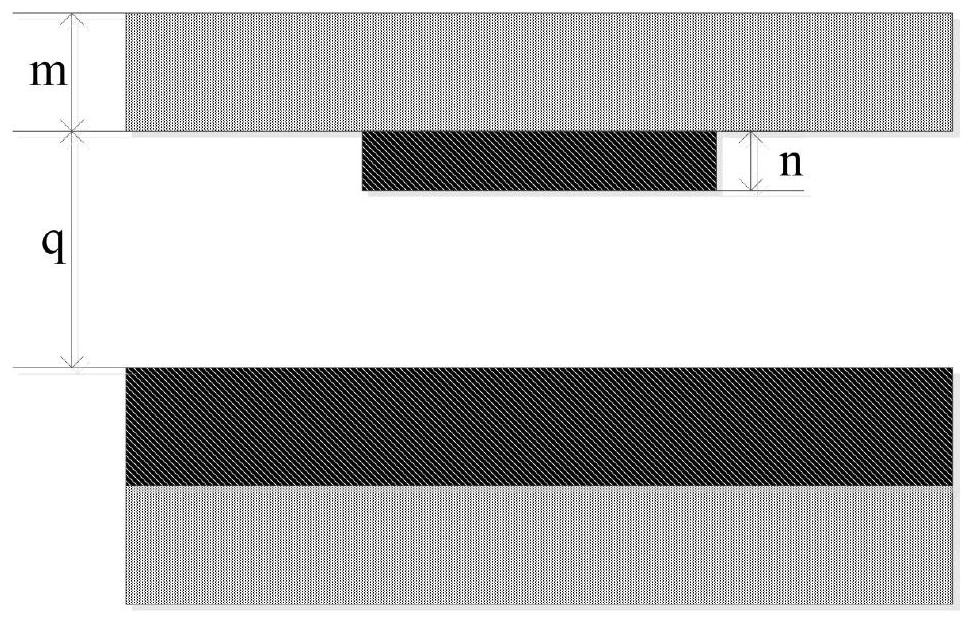

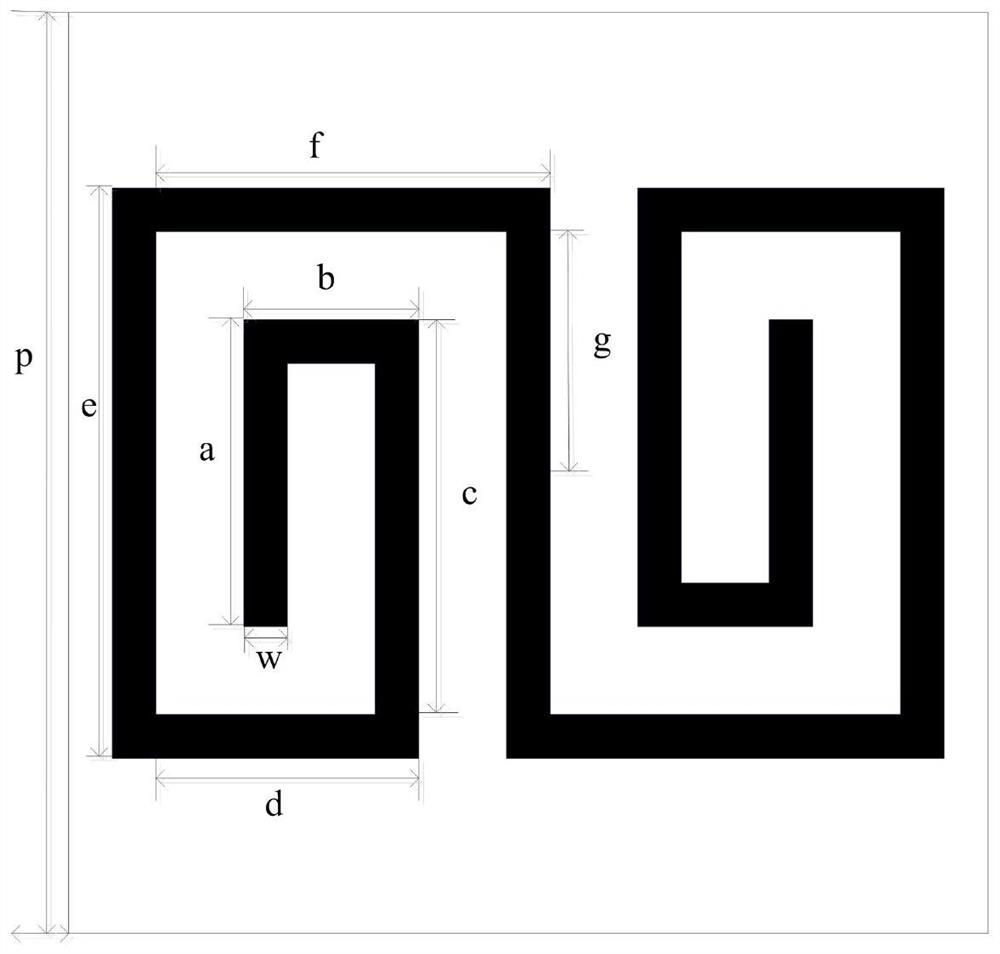

[0050] like figure 2 , image 3 and Figure 4 As shown, the thickness m of the cover layer 1 is 50 μm, the thickness n of the metal rectangular resonant array 2 is 0.2 μm, the height q of the microfluidic channel 5 is 10 μm, the side length p of the square unit period is 120 μm, and the inner and outer rings The width w is 6 μm, the length a of the first resonant portion is 15 μm, the length b of the second resonant portion is 4 μm, the length c of the third resonant portion is 74 μm, the length d of the fourth resonant portion is 31 μm, and the length of the fifth resonant portion The length e of the sixth resonant portion is 90 μm, the length f of the sixth resonant portion is 52 μm, and the length g of the seventh resonant portion is 39 μm.

[0051] The distance h between the first resonance part and the third resonance part is 4 μm, the distance i between the first resonance part and the fourth resonance part is 5 μm, and the distance j between the first resonance part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com