Novel waste treatment equipment special for veterinarian

A technology for processing equipment and waste, applied in grain processing, lighting and heating equipment, combustion types, etc., can solve the problems that waste bacteria cannot be effectively eliminated and affect the external environment, so as to achieve suitable promotion and use and reduce pollution , Improve the effect of incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

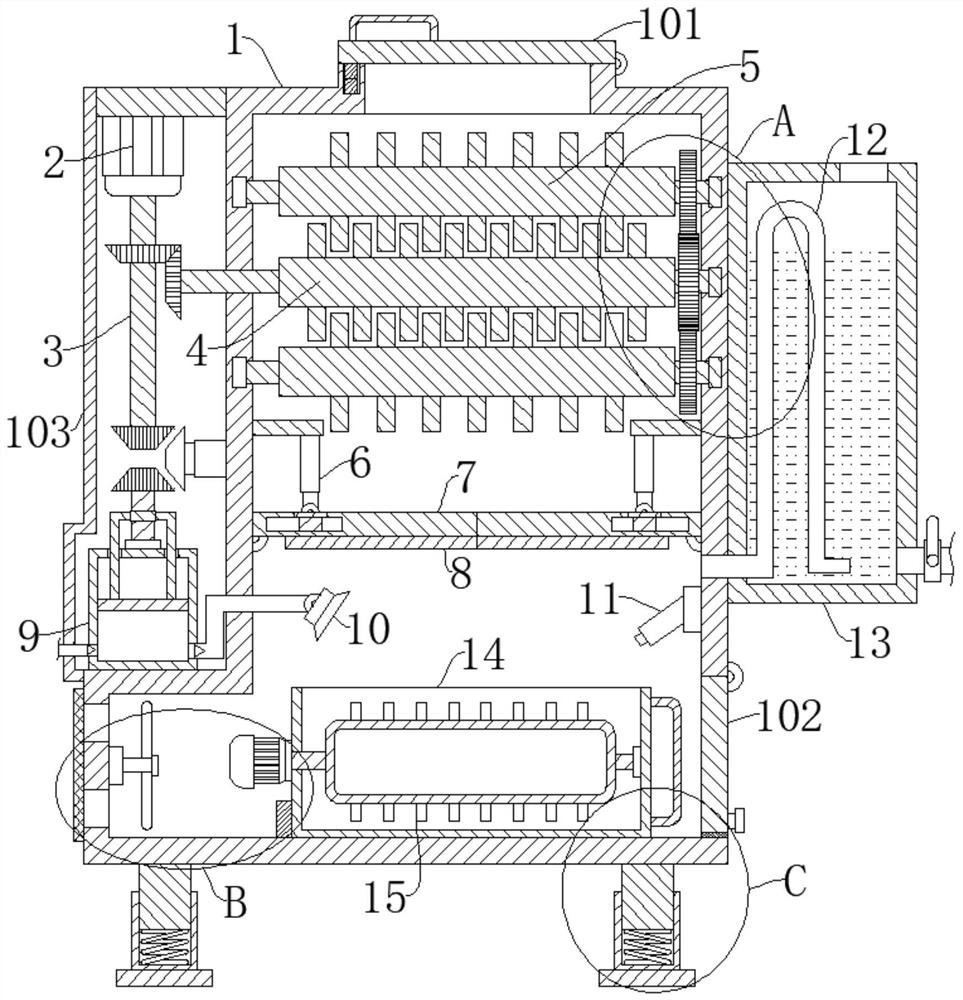

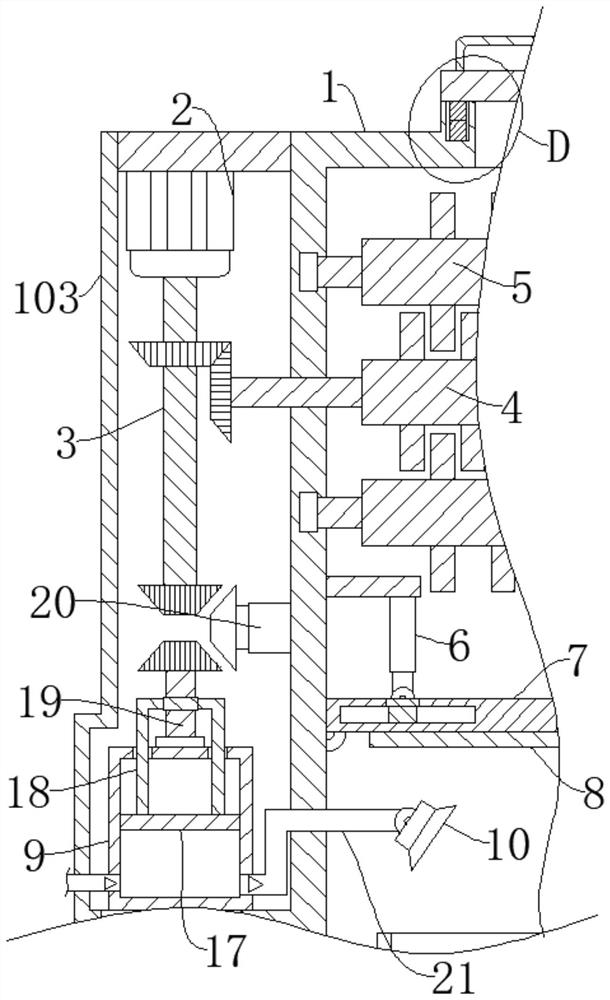

[0031] refer to Figure 1-7 , a new type of waste disposal equipment dedicated to veterinary medicine, including a box body 1 and a box cover 101, the box cover 101 is connected to the box body 1 through hinges, and the end of the box body 1 close to the feeding port is connected with a The crushing mechanism, the lower end of the casing 1 close to the crushing mechanism is rotatably connected with a sealing plate 7, the two sides of the inside of the casing 1 are fixedly connected with the first electric push rod 6 through the fixed plate, and the telescopic end of the first electric push rod 6 is rotatably connected with a slide block, the sealing plate 7 is provided with a chute matching the slider, one side of the box body 1 is connected with a driving mechanism, the crushing mechanism is connected with the driving mechanism, and a combustion box 14 is placed at the lower end of the box body 1, and the combustion box 14 One side of one side is fixedly connected with a seco...

Embodiment 2

[0034] refer to Figure 1-2 , a new type of veterinary dedicated waste treatment equipment, which is basically the same as that of Embodiment 1, furthermore: the drive mechanism includes a first motor 2 and an output shaft 3, and the first motor 2 is fixedly connected to a part of the box body 1 through a support plate. On the side, the output shaft 3 is fixedly connected to the output end of the first motor 2, and the first bevel gear is fixedly connected to the output shaft 3. When the equipment is working, the first motor 2 is started at this time, and the first motor 2 drives the output shaft 3 To rotate, the first output shaft 3 drives the first bevel gear to rotate, and the first bevel gear drives the crushing mechanism to work to crush the waste. The output shaft 3 can also drive the combustion aid injection mechanism to work through the transmission assembly. Therefore, the crushing mechanism and the combustion aid injection mechanism only need one driving mechanism to...

Embodiment 3

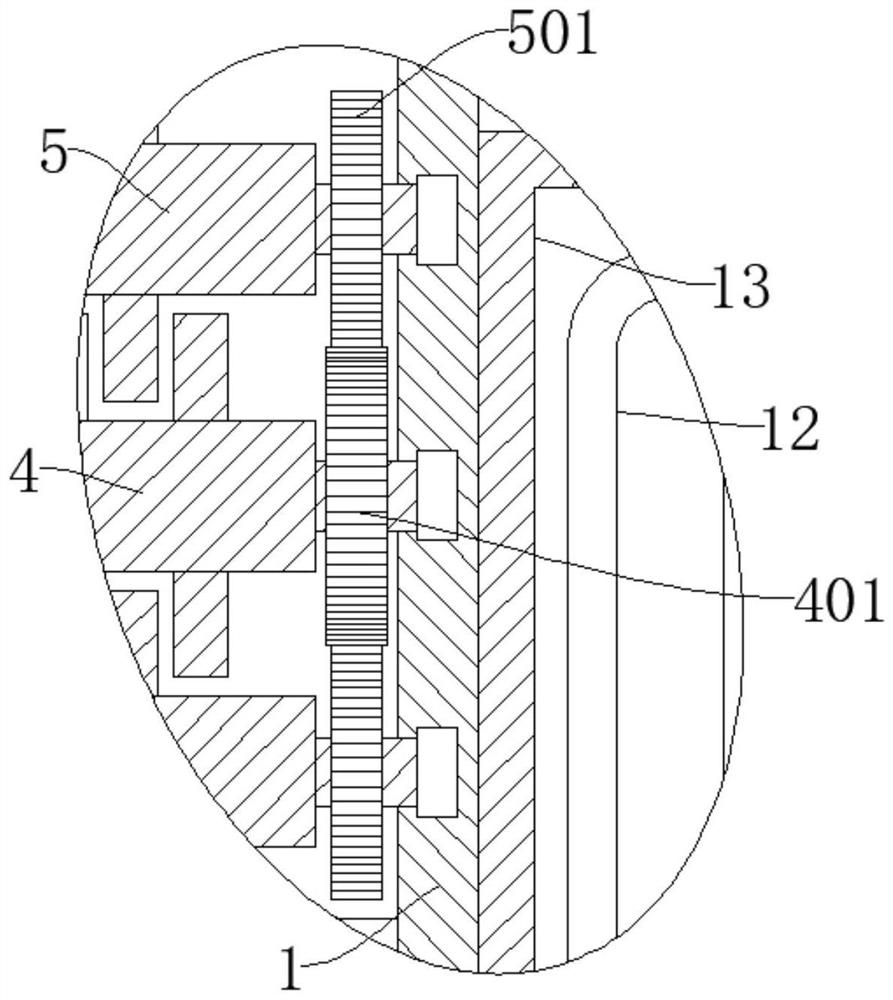

[0036] refer to Figure 1-3 , a new type of veterinary waste treatment equipment, which is basically the same as that of Embodiment 1, and furthermore: the crushing mechanism includes a first crushing gear 4 and a second crushing gear 5, and the first crushing gear 4 and the second crushing gear 5 are both Rotationally connected in the casing 1, the crushing teeth on the first crushing gear 4 and the second crushing gear 5 are meshed, the end of the first crushing gear 4 near the output shaft 3 penetrates the casing 1, and is fixedly connected with the first The second bevel gear meshed with the bevel gear, the first crushing gear 4 is fixedly connected with the first gear 401 at the end away from the output shaft 3, and the second crushing gear 5 is fixedly connected with the second gear 501 meshing with the first gear 401 , when the staff pours the waste into the box body 1 through the feed port, the driving mechanism drives the first crushing gear 4 to rotate, and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com