Construction site assembled steel pipe threaded hole fluting apparatus for high-end equipment manufacturing

A technology for construction sites and slotting equipment, which is applied in the direction of manufacturing tools, metal processing equipment, drilling/drilling equipment, etc., which can solve the problems of low processing efficiency, long processing time, and large manpower consumption to achieve precise slotting , keep clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

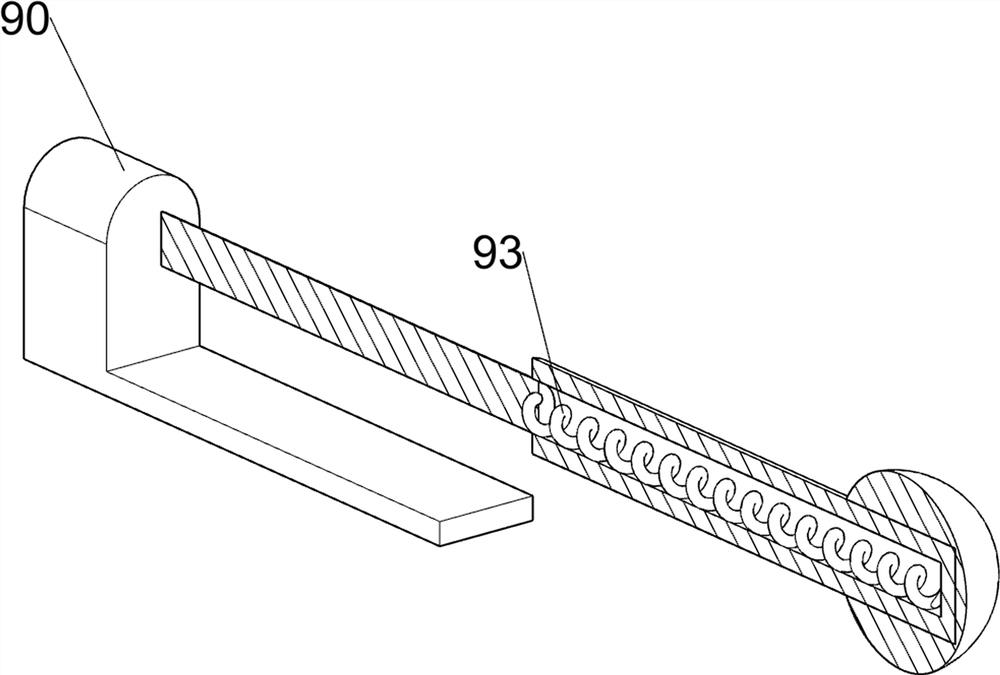

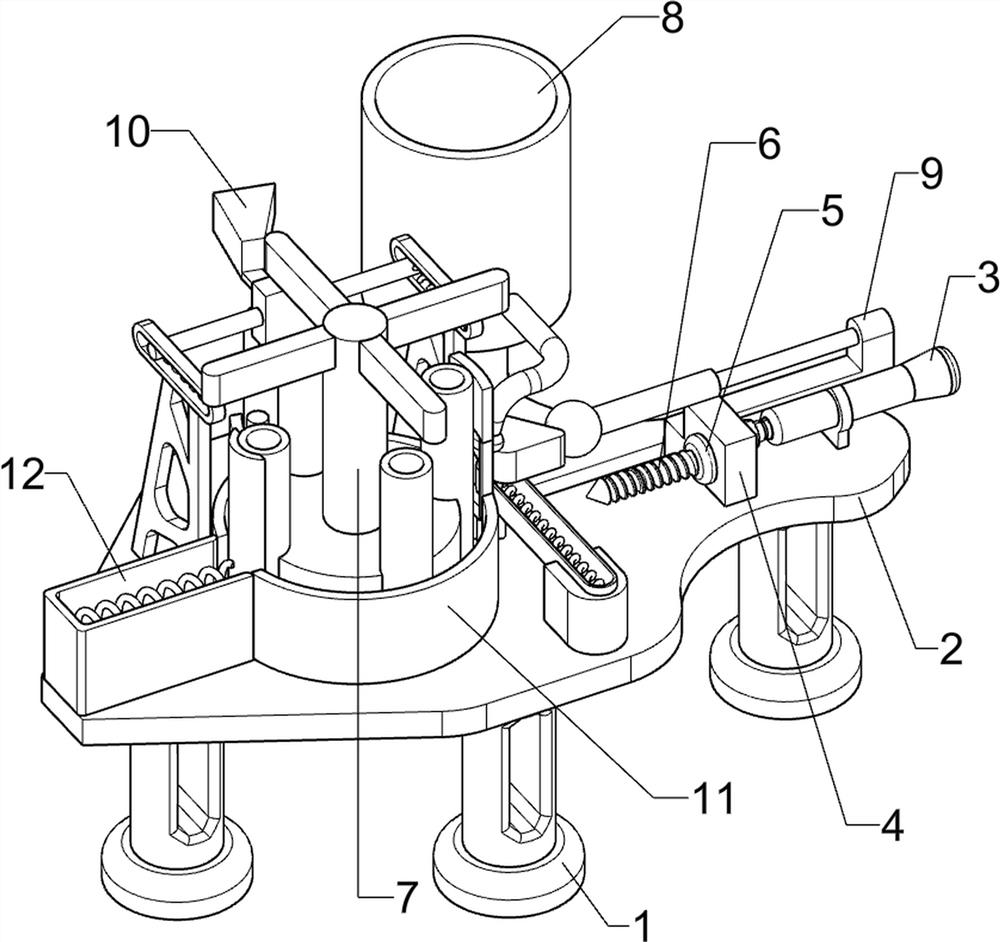

[0067] A high-end equipment manufacturing site assembly steel pipe threaded hole slotting equipment, such as figure 1 As shown, it includes a base 1, a mounting plate 2, a cylinder 3, a first connecting plate 4, a brushless motor 5, a tapping drill 6, a transport mechanism 7 and a cooling mechanism 8, which is provided with three bases 1, and the top of the base 1 There is a mounting plate 2 between them, and the right part of the mounting plate 2 is provided with a cylinder 3, the cylinder 3 is provided with a first connecting plate 4, the first connecting plate 4 is provided with a brushless motor 5, and the brushless motor 5 is provided with a tapping Wire drill bit 6, mounting plate 2 left parts are provided with transportation mechanism 7, and mounting plate 2 right rear parts are provided with cooling mechanism 8.

[0068] When people need to slot the material, they place the material on the mounting plate 2, and then they start the cylinder 3 and the brushless motor 5, ...

Embodiment 2

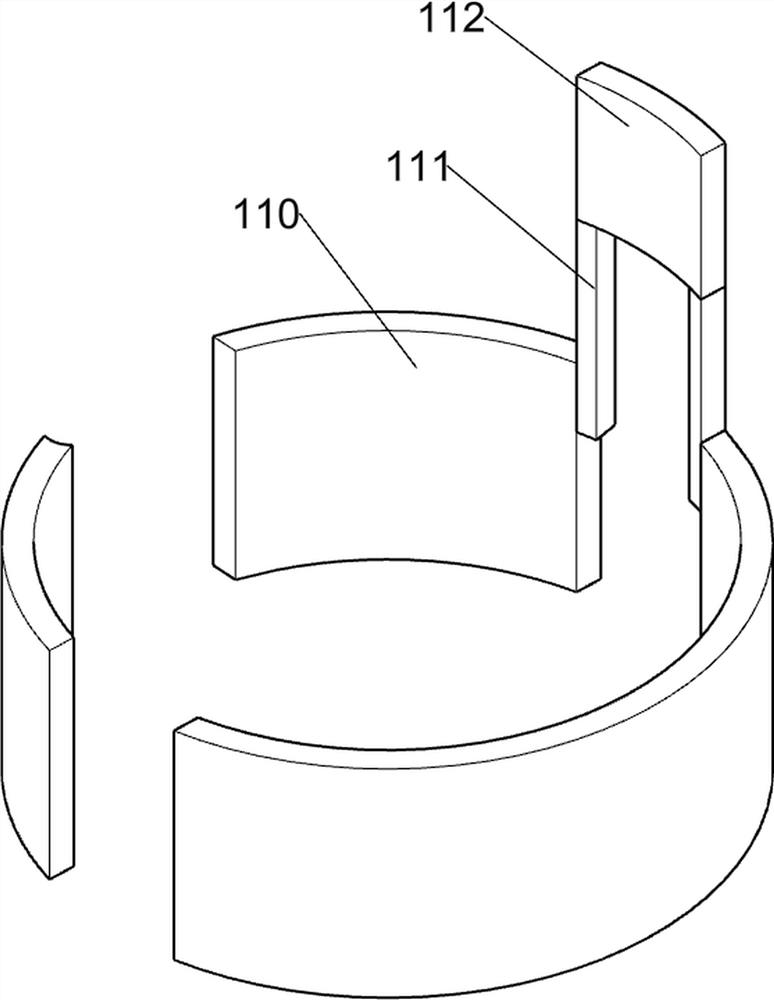

[0070] On the basis of Example 1, such as Figure 2 to Figure 8 As shown, the transportation mechanism 7 includes a rack 70, a rotating shaft 71, a gear 72, a one-way clutch 73 and a sheave 74, the first connecting plate 4 is provided with a rack 70, and the left part of the mounting plate 2 is rotationally connected with a rotating shaft 71 The bottom of the rotating shaft 71 is provided with a gear 72, the gear 72 cooperates with the rack 70, the bottom of the rotating shaft 71 is provided with a one-way clutch 73, and the rotating shaft 71 is provided with a sheave 74.

[0071] When people need to slot the material, people place the material on the left part of the mounting plate 2 to contact the sheave 74, and then people start the cylinder 3 and the brushless motor 5, and the cylinder 3 drives the first connecting plate 4 and the brushless motor 5. The tapping bit 6 and the rack 70 move to the left, the rack 70 meshes with the gear 72, drives the gear 72, the one-way clutch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com