Environment-friendly type stone surface maintenance method

An environmentally friendly, stone technology, applied in stone processing equipment, stone processing tools, coatings, etc., can solve the problems of poor stone surface maintenance, non-environmental protection of coating materials, and large environmental pollution, so as to achieve environmental protection. Fast curing speed and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

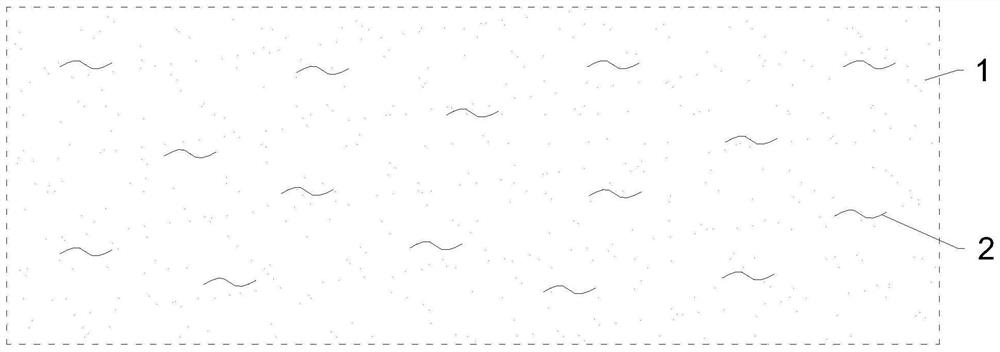

[0038] see figure 1 A maintenance method for an environment-friendly stone surface, which includes the following steps:

[0039] Step 1. Grinding the surface of the stone and cleaning up the debris generated during the grinding process;

[0040] Step 2, filling the cracks or sunken surfaces on the stone surface with a supplementary layer;

[0041] Step 3. After the supplementary layer is solidified, polish the stone surface again, so that the solidified supplementary layer is consistent with the stone surface;

[0042] Step 4. According to the size of the surface area of the stone to be treated, shake the crystalline paint evenly and sprinkle it evenly on the surface of the stone to crystallize the surface of the stone and form a hard and dense protective layer.

[0043] Before grinding the stone surface, clean the stone surface to remove dust, particles and other impurities, and keep the stone surface dry, so that during the process of grinding the stone surface, dust, pa...

Embodiment 2

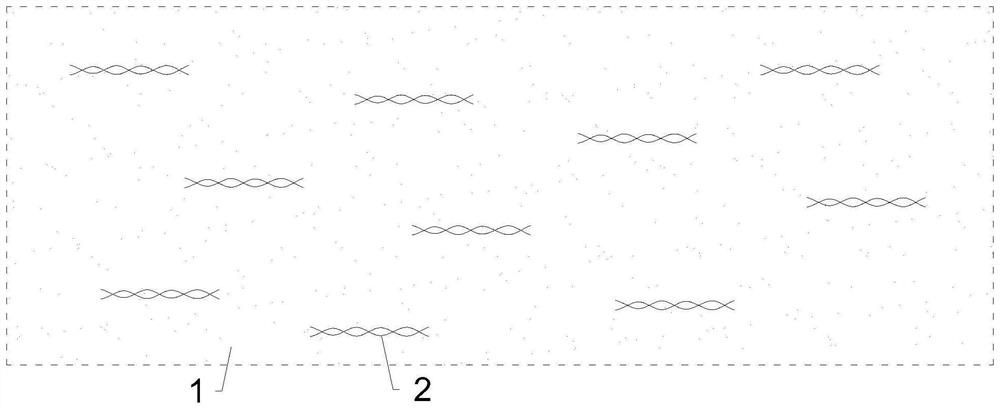

[0057] see figure 2 , superfine fibers (2) are dispersed in the modified epoxy resin slurry (1) in a spiral shape, and the spiral superfine fibers (2) are formed by twisting at least two filamentary fibers, which can make the prepared supplement layer for better abrasion resistance, water absorption and stretch resistance.

[0058] The difference between embodiment two and embodiment one is: the morphology of the ultrafine fiber (2) in embodiment two is different, and the helical ultrafine fiber (2) in embodiment two is more than single filamentary ultrafine fiber For the fiber (2), the structure is more stable, so that the obtained supplementary layer has better wear resistance, water absorption and stretch resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com