Multifunctional clamping jaw for injection molding machine assembly

An injection molding machine, multi-functional technology, applied in the direction of chuck, claw arm, manipulator, etc., can solve the problems of cumbersome equipment installation and debugging, high overall cost, complex mechanism, etc., and achieve ingenious design, simple structure, stable and reliable clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

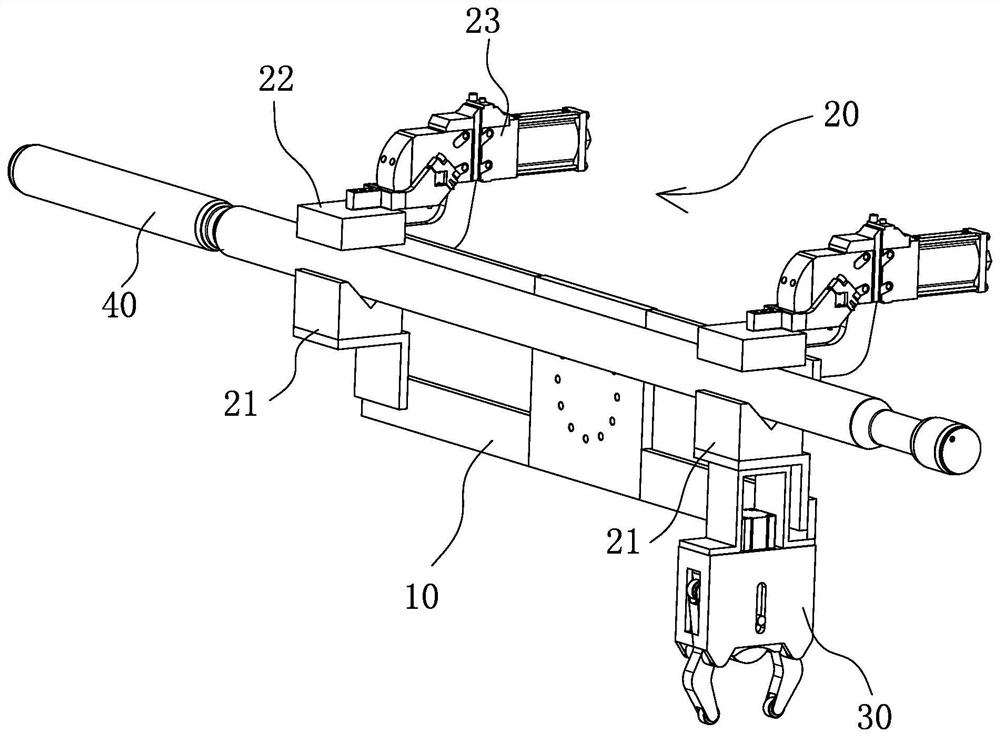

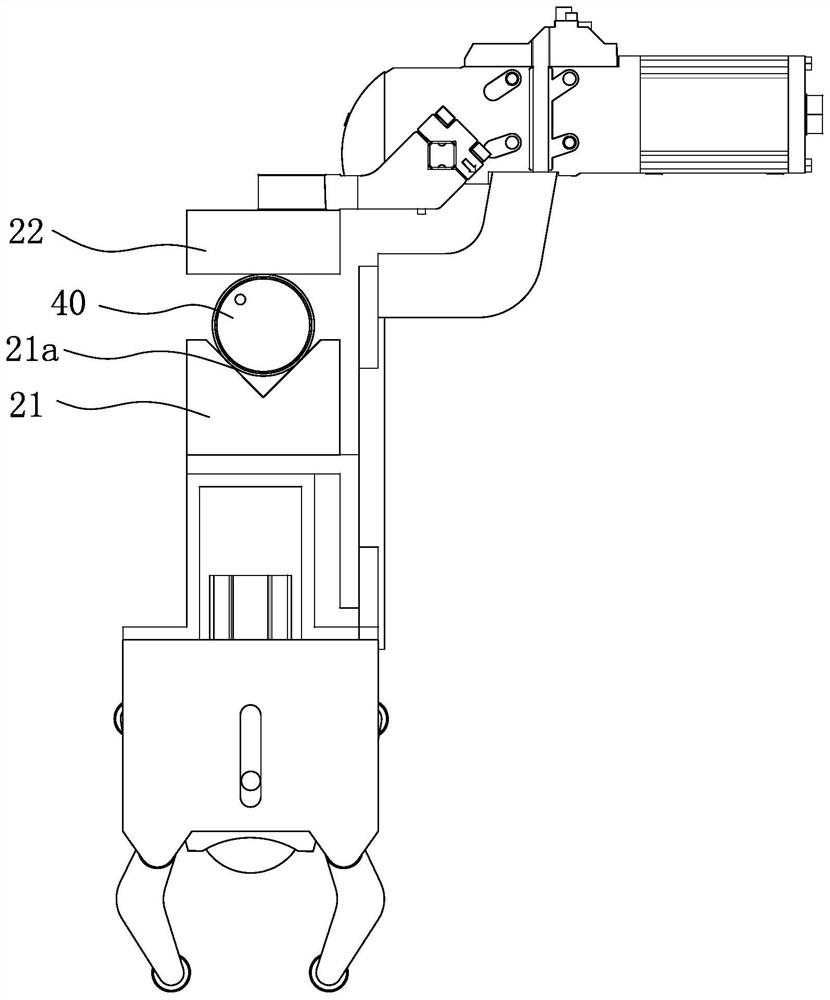

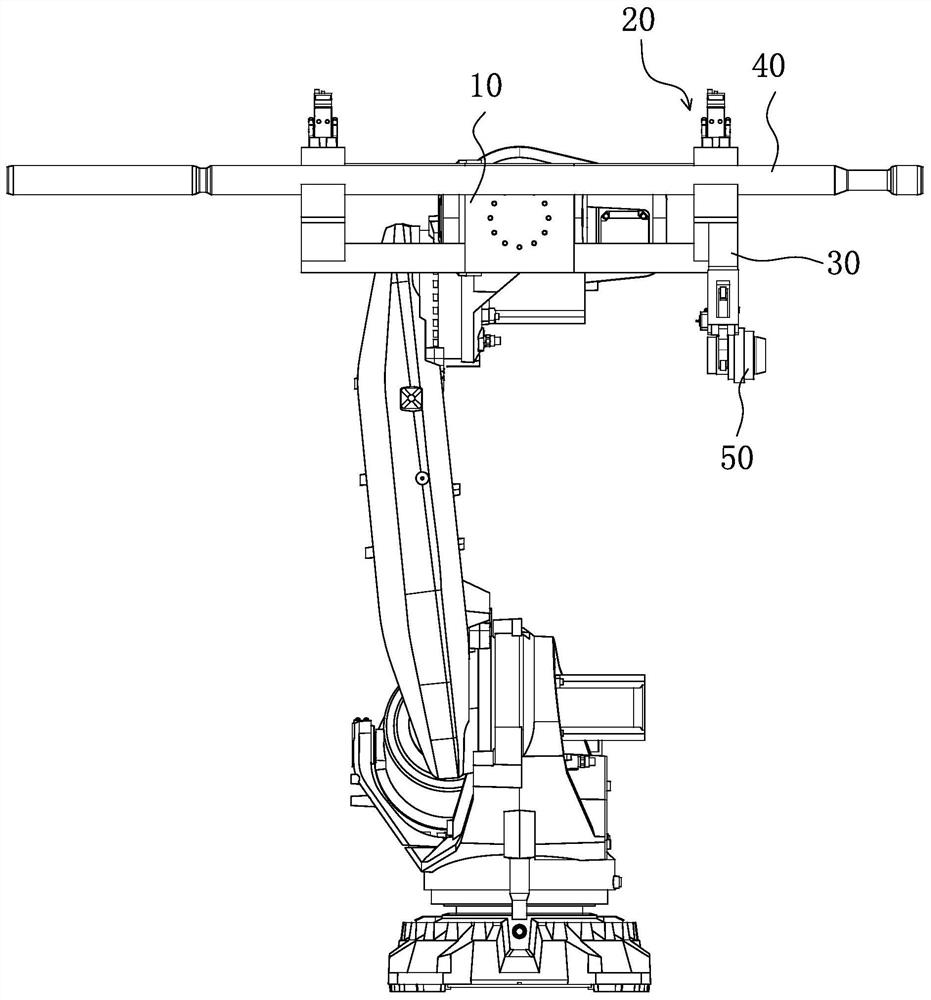

[0031] like Figure 1 to Figure 3 As shown, the multifunctional clamping jaw used for assembling the injection molding machine includes a bracket 10 , a tie rod clamping assembly 20 , and a nut clamping assembly 30 .

[0032] The tie rod clamping assembly 20 includes two lower clamping blocks 21 installed on the front side of the bracket 10, the two lower clamping blocks 21 are located at the same level, and each lower clamping block 21 is correspondingly provided with a clamping cylinder 23 connected to the bracket 10 , the clamping cylinder 23 is located at the rear side of the bracket 10, the swing arm of the clamping cylinder 23 is connected with the upper clamping block 22, and the clamping cylinder 23 can drive the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com