Fabricated floor slab hoisting and positioning device for green building construction

A technology of green building and positioning device, applied in construction, hoisting device, building structure, etc., can solve the problems of large force on hoisting equipment, long moving distance, rope wear, etc., to reduce the use of rope for a long time, Ensure stability and reduce the effect of buffer strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

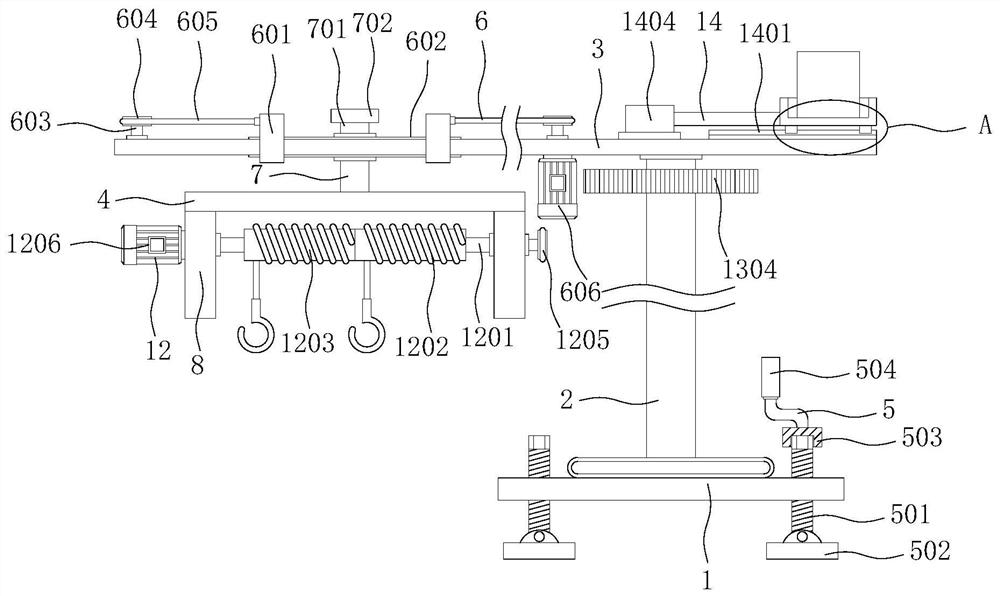

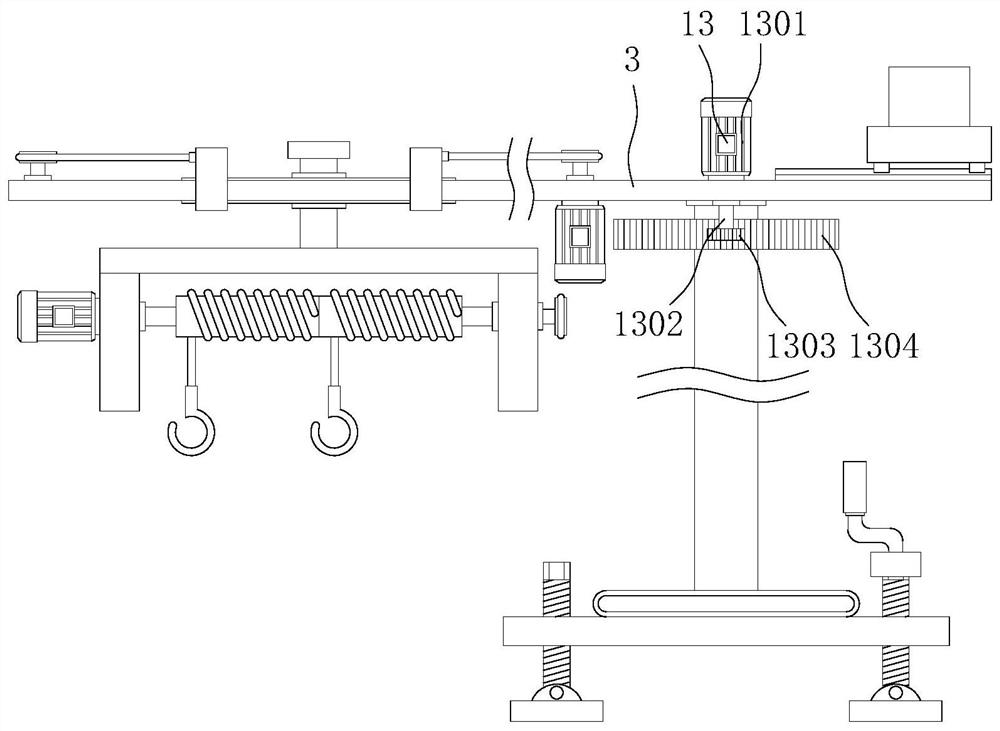

[0027] see Figure 1-7 , the present invention provides a technical solution: a prefabricated floor hoisting and positioning device for green building construction, comprising a base 1, a support column 2 is fixedly installed on the top of the base 1, a top plate 3 is installed on the top of the support column 2, and the top plate 3 The bottom of the rotating plate 4 is provided, the base 1 is provided with a leveling mechanism 5, the upper part of the top plate 3 is provided with a transport mechanism 6, a rotating mechanism 7, a rotating mechanism 13 and an adjusting mechanism 14, and the bottom of the rotating plate 4 is fixedly installed with two sets of The annular plates 8 and the two groups of annular plates 8 are provided with a movable plate 10 inside, and a contraction mechanism 12 is provided under the rotating plate 4 .

[0028] Further, the inner top and bottom of the annular plate 8 are fixedly equipped with a slide bar 9, the movable plate 10 is slidably install...

Embodiment 2

[0030] see Figure 1-7On the basis of Embodiment 1, the leveling mechanism 5 includes a threaded rod 501, a spacer 502, a block 503 and a rotating handle 504. The base 1 is threaded with a threaded rod 501, and the bottom end of the threaded rod 501 is hingedly mounted with a pad Block 502, the top of the threaded rod 501 is hexagonal, the top of the threaded rod 501 is engaged with a block 503, the top of the block 503 is fixed with a rotating handle 504, and the rotating handle 504 is turned, and the rotating handle 504 drives the block 503 and threaded rod 501 are rotated, and the height of the four corners of the base 1 can be adjusted, so that the device can maintain the vertical direction of the base 1 during the lifting process, thereby keeping the top plate 3 stable and preventing the device from Misalignment occurs, causing the device to tip over.

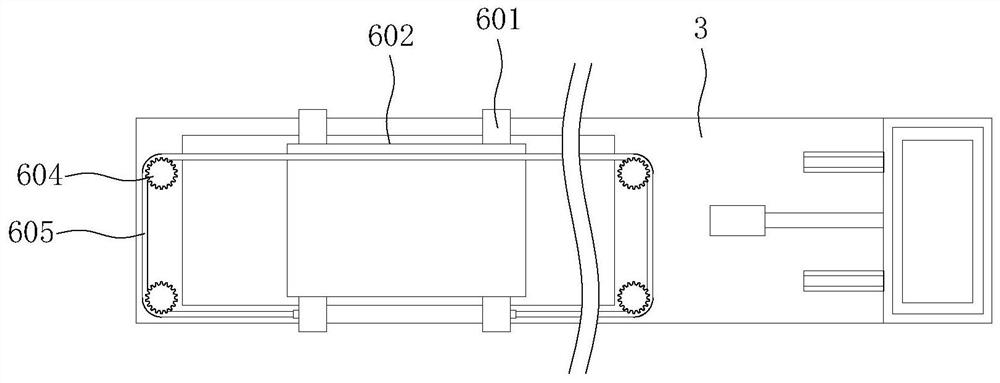

[0031] Further, the transportation mechanism 6 includes a slider 601, a transportation plate 602, a rotating shaft 603,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com