Automobile glass forming die and production method thereof

A technology for automotive glass and forming molds, applied in the field of mold manufacturing, can solve the problems of unbalanced and stable laminated glass, poor production consistency, and pressing, so as to improve the overall optical quality and overall profile, reduce overall profile fluctuations, and improve production quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The content of the present invention will be further described below in conjunction with the accompanying drawings.

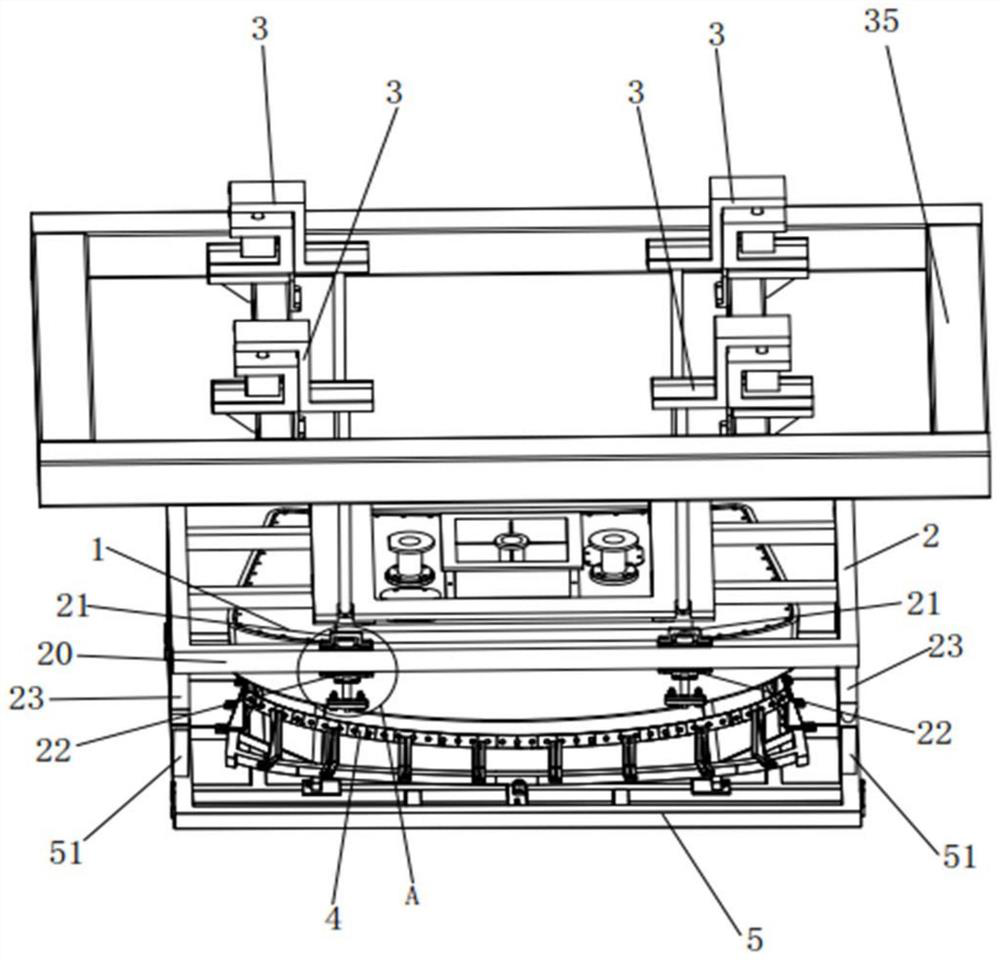

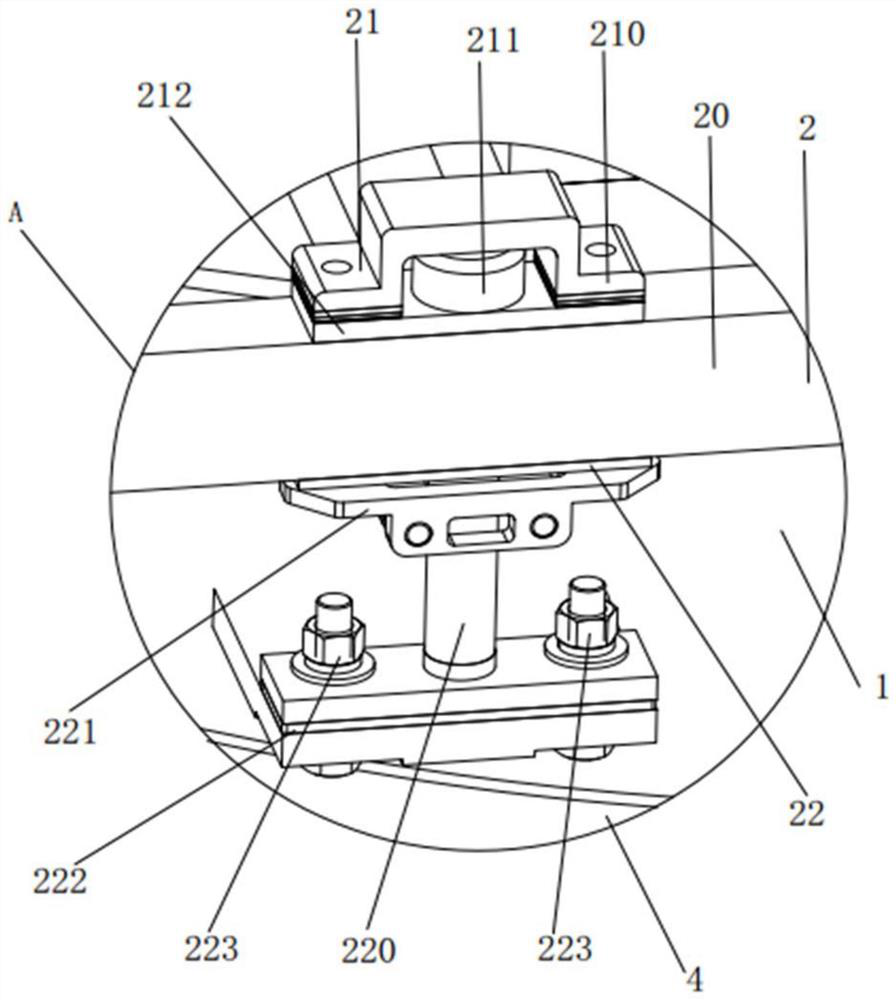

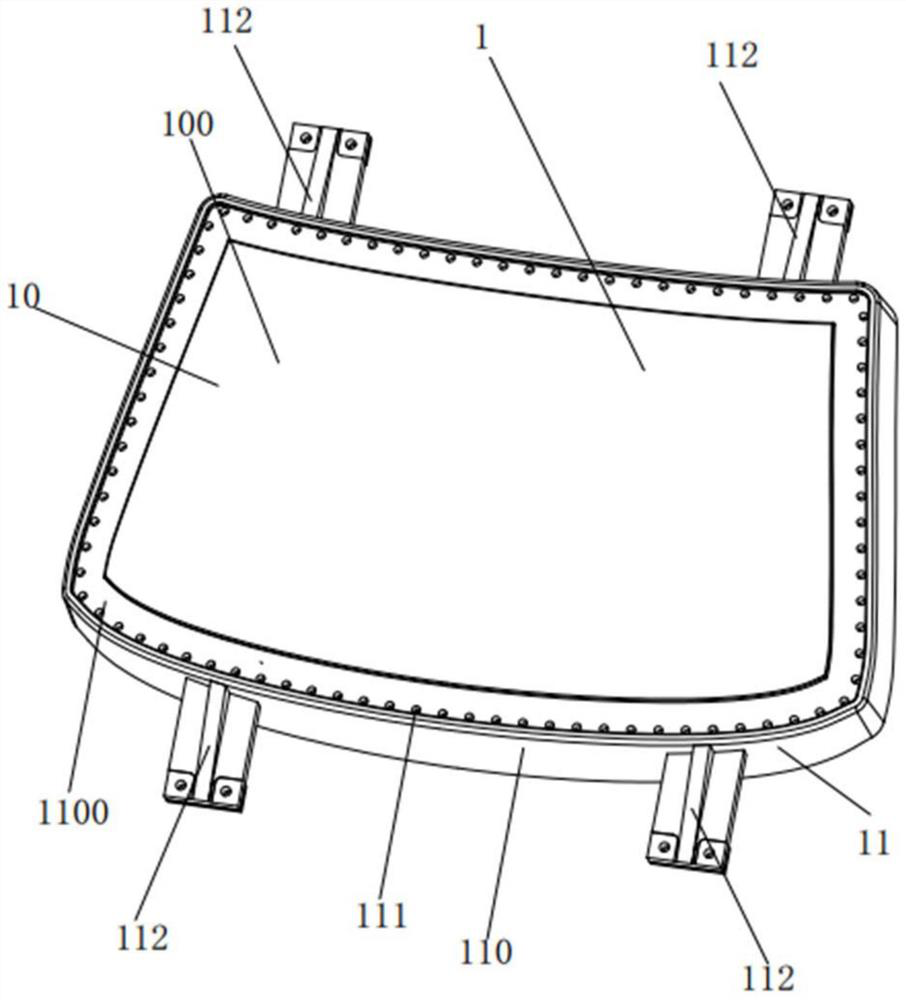

[0036] like Figure 1 to Figure 9As shown, a molding mold for automobile glass according to the present invention includes an upper punch 1, an upper frame 2, a lower die 4 and a lower frame 5, and the upper punch 1 is fixed directly below the upper frame 2 , the upper punch 1 has the same convex surface as the shape of the automobile glass; the lower die 4 is fixed directly above the lower frame 5, and the lower die 4 has the same outer concave surface as the shape of the automobile glass, The outer convex surface of the upper punch 1 is set corresponding to the outer concave surface of the lower die 4, and the lower die 4 is used to carry a plurality of glass plates; the upper punch 1 includes a plurality of vacuum holes 111, more A plurality of vacuum holes 111 are arranged around the edge portion of the outer convex surface of the upper punch 1, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap