Micro-interface reaction system and method for preparing butyraldehyde through propylene carbonylation

A propylene carbonyl and interfacial reaction technology, applied in the field of propylene hydroxylation reaction preparation, can solve the problems of short service life of catalyst, high energy consumption, increase production cost of enterprises, etc., so as to improve the distribution of bubbles, strengthen interaction, and promote uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

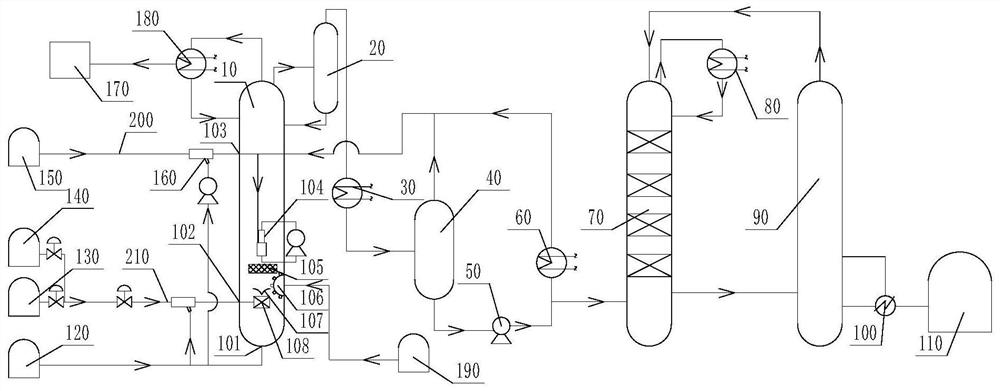

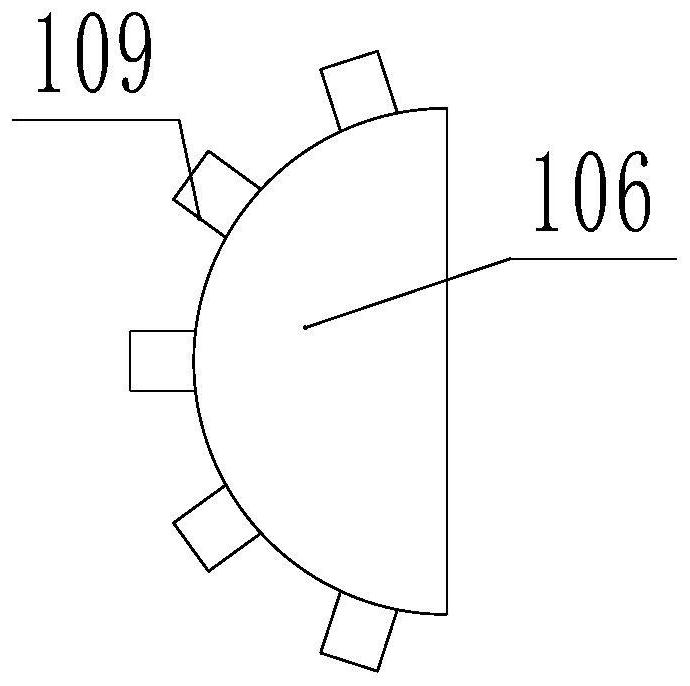

[0066] refer to Figure 1-3 As shown, this embodiment provides a micro-interface reaction system for the carbonylation of propylene to butyraldehyde, including: a solvent storage tank 120, a reactor 10, a gas-liquid separator 40, a propylene storage tank 150, a carbon monoxide storage tank 130, a hydrogen Storage tank 140, propylene pipeline 200 and synthesis gas pipeline 210; the side wall of reactor 10 is provided with propylene inlet 103 and synthesis gas inlet 102 in sequence from top to bottom; the bottom of reactor 10 is provided with solvent inlet 101, and solvent inlet 101 is connected with solvent Storage tanks 120 are connected; a mist eliminator 20 is installed between the reactor 10 and the gas-liquid separator 40; the product in the reactor 10 is demistered by the mist eliminator 20 and then flows into the gas-liquid separator 40 for gas-liquid separation.

[0067] The outlet of the gas-liquid separator 40 is connected with a third condenser 60 ; part of the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com