Energy accumulator arrangement structure and excavator

A technology for arranging structures and accumulators, which is applied in the direction of earthmoving machines/shovels, construction, etc., can solve the problems of environmental pollution, disassembly, and assembly difficulty, and achieves lower production costs, greater disassembly difficulty, and savings. The effect of cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

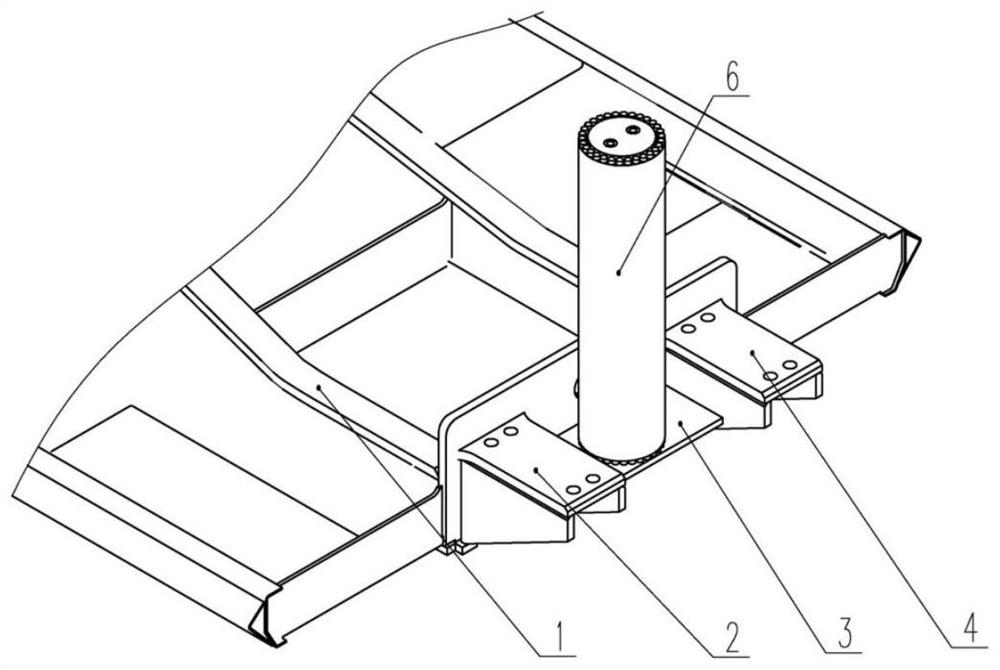

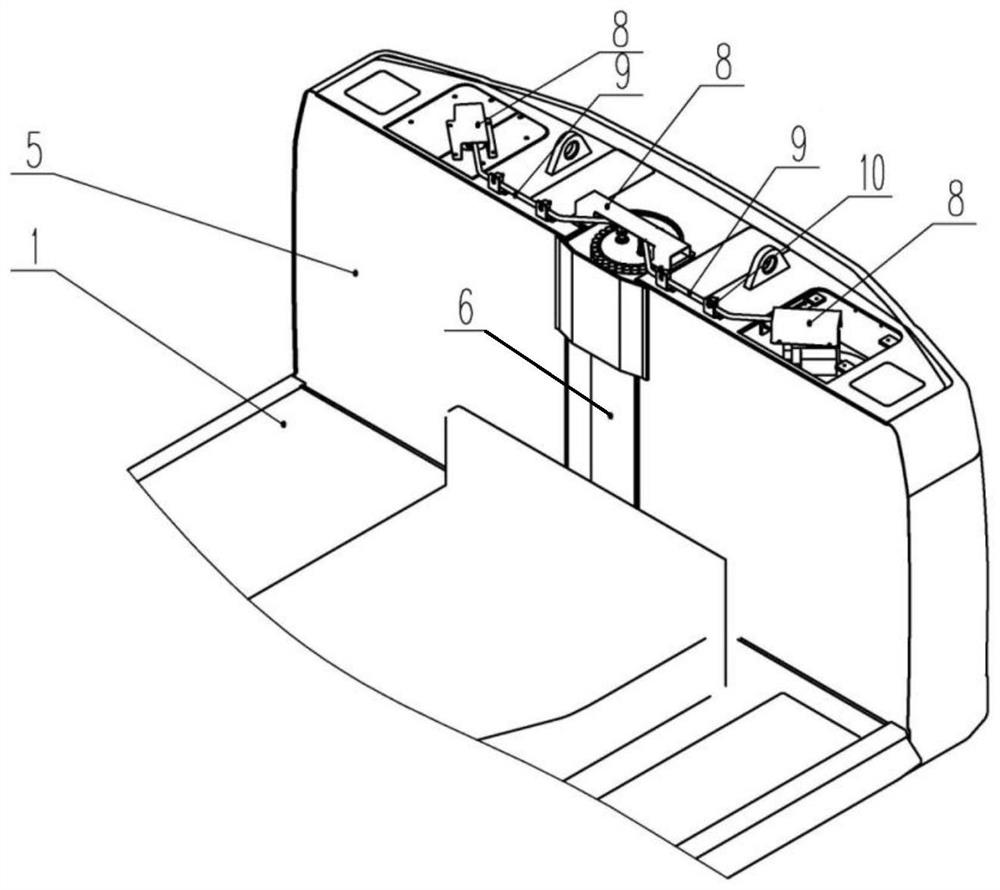

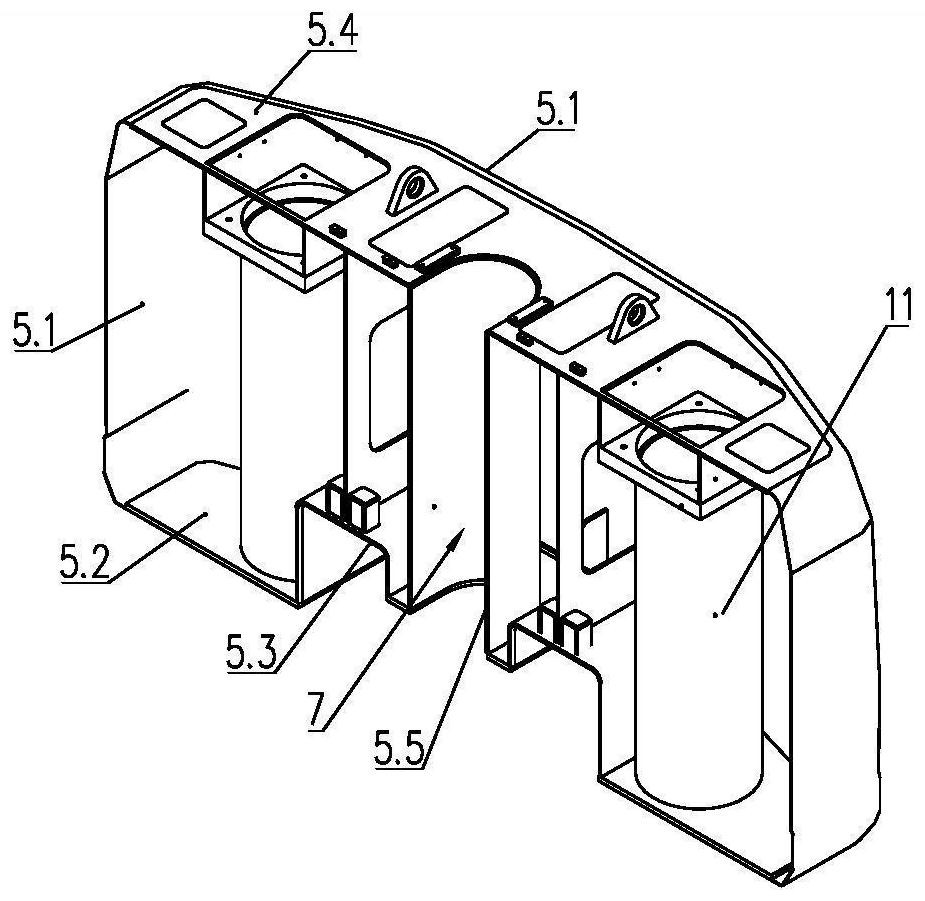

[0034] Such as figure 1 , figure 2 As shown, the tail end of the slewing platform 1 is fixedly provided with a first counterweight support plate 2, an accumulator support plate 3, and a second counterweight support plate 4, and the accumulator support plate 3 is located between the two first and second counterweights. Between the support plates, and the accumulator support plate 3 is welded and fixed with two counterweight support plates at the same time, wherein the first counterweight support plate 2 and the second counterweight support plate 4 have mounting holes above, fasteners (such as Bolts) pass through the mounting holes to install the counterweight component 5 on the first and second counterweight support plates, and the accumulator support plate 3 is provided with a notch (not shown) and a mounting hole (not shown). In the installation of accumu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com