Intelligent control method and device for sensitivity of automatic ball valve sensing system

A technology of induction system and intelligent control, applied in valve operation/release device, valve device, pipeline system, etc., can solve the problems of waste of resources, poor control reliability, low control accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

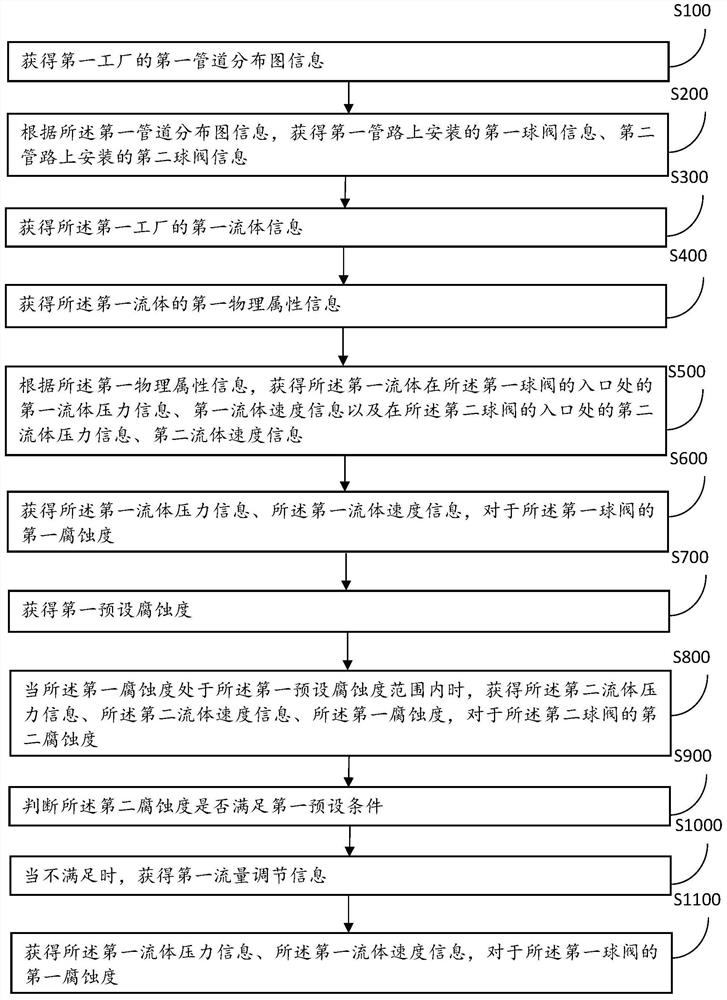

[0036] figure 1 A flow diagram of an intelligent control method for a sensitivity of an automatic ball valve induction system in an embodiment of the present invention. The method is applied to a ball valve induction system, wherein the ball valve sensing system has a smart control terminal that controls multiple automatic ball valves, such as figure 1 As shown, the embodiment of the present invention provides an intelligent control method of the sensitivity of an automatic ball valve induction system, the method comprising:

[0037] Step 100: Get the first pipeline distribution map information of the first factory;

[0038] Step 200: According to the first pipe distribution graph information, the first ball valve information installed on the first conduit is obtained, and the second ball valve information mounted on the second pipeline is obtained.

[0039] Specifically, the ball valve sensing system in this embodiment is a system for monitoring, management and analysis, and war...

Embodiment 2

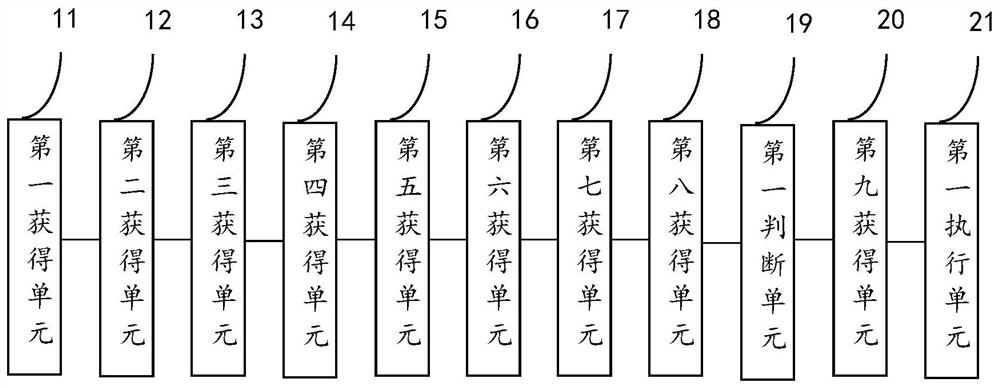

[0099] According to an intelligent control method according to a sensitivity of an automatic ball valve induction system in the foregoing embodiment, the present invention also provides an intelligent control device for automatic ball valve induction system sensitivity, which is applied to a ball valve induction system, wherein The ball valve induction system has a smart control terminal that controls multiple automatic ball valves, such as figure 2 As shown, the apparatus comprises:

[0100] The first obtaining unit 11, the first obtaining unit 11 is used to obtain the first pipe distribution map information of the first factory;

[0101] The second obtaining unit 12, the second obtaining unit 12 is used to obtain a first ball valve information installed on the first line according to the first pipeline distribution map information;

[0102] The third obtaining unit 13, the third obtaining unit 13 is used to obtain a first fluid information of the first factory;

[0103] The four...

Embodiment 3

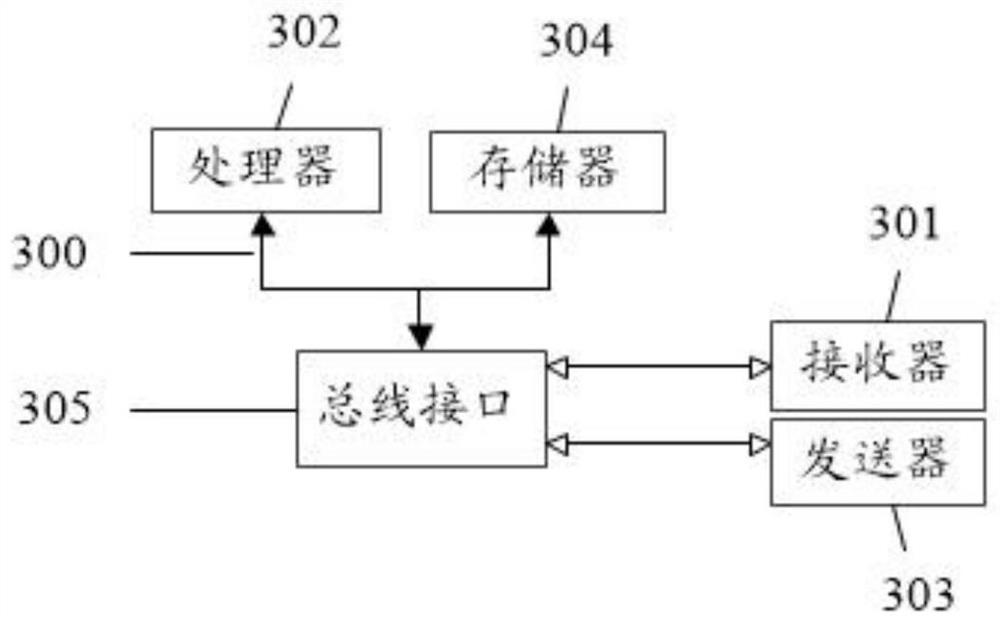

[0149] Based on the intelligent control method of the sensitivity of an automatic ball valve induction system in the foregoing embodiment, the present invention also provides an exemplary electronic device, such as image 3 As shown, including the memory 304, the processor 302, and a computer program stored on the memory 304 and can run on the processor 302, the processor 302 performs the procedure of the procedure as described above inductive sensitivity The step of any method of the intelligent control method.

[0150] Among them, image 3 In the bus architecture (representing the bus 300), the bus 300 can include any number of interconnected bus and bridge, and bus 300 will include various types of memory representative represented by processor 302 and memory 304. The circuit links together. The bus 300 can also link various other circuits such as peripherals, regulators, and power management circuits, which are well known in the art, and therefore, this paper will not be further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com