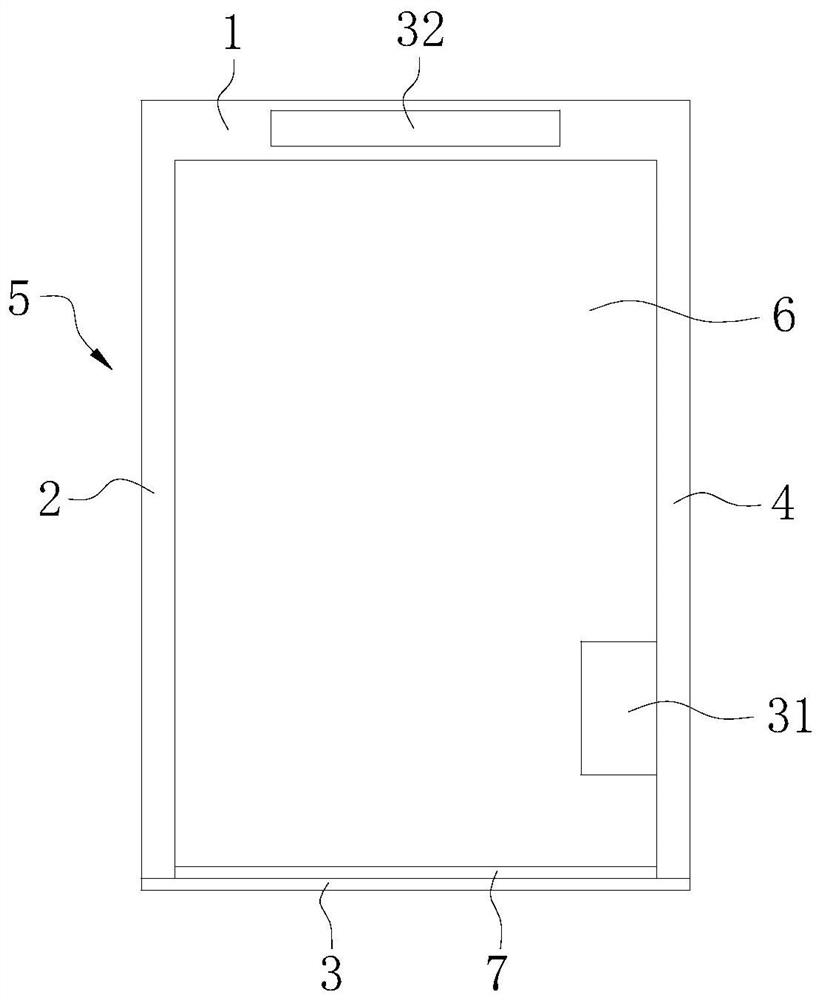

Toilet mirror with cleaning function

A vanity mirror and functional technology, applied in the field of vanity mirrors, can solve problems such as hitting the reset coil box, affecting the service life of the reset coil box, and generating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

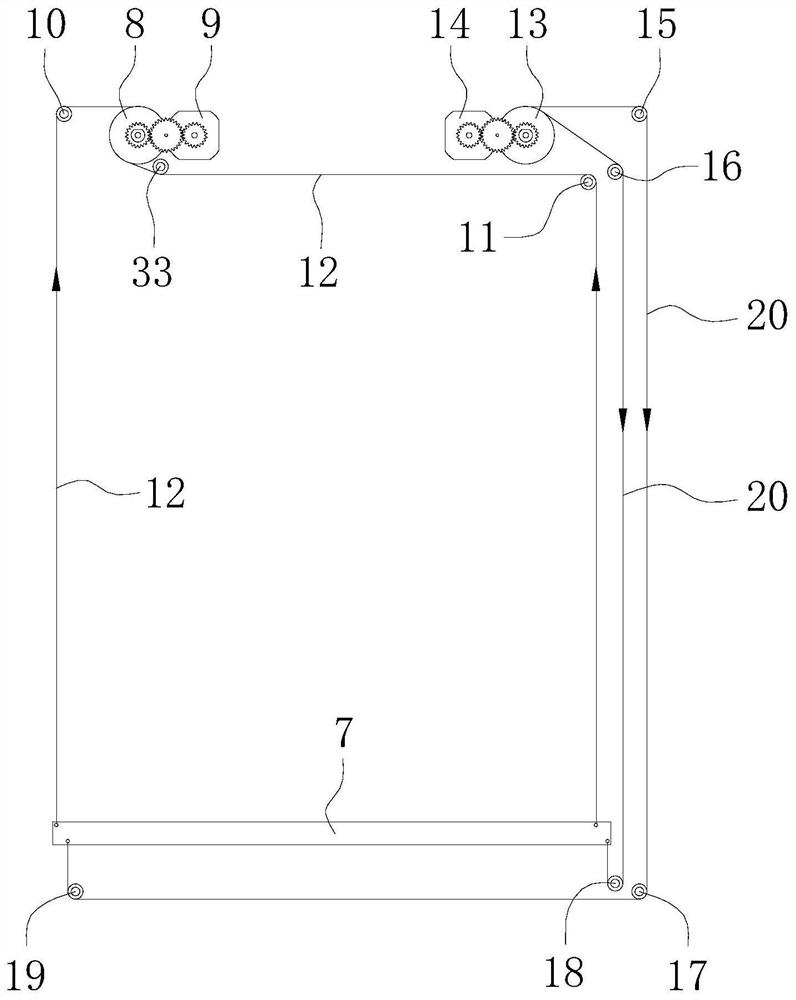

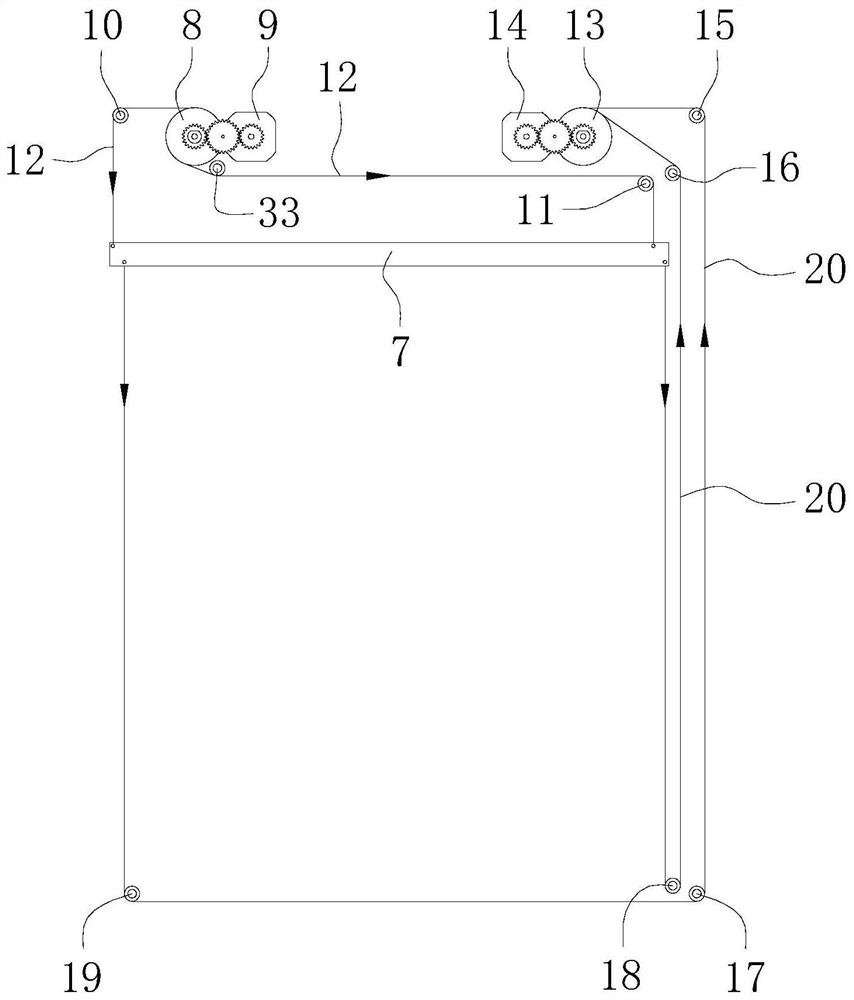

[0085] As an embodiment, the second drive mechanism may include a third motor fixed below the upper frame 1, and the other end is fixed on the output shaft of the third motor, and the other end is fixed to the upper end of the imaging mirror 6. When working, the third motor drives the output shaft to rotate, wrap the drawntrope on the output shaft of the third motor, and then pull the upper end of the imaging mirror 6 to pull down by drawing.

[0086] Preferably, continue to see Figure 9 to 13 The second drive mechanism includes a steering machine 28 and a drawn cord 29; the steering machine 28 is disposed on the back side of the imaging mirror 6, and is fixed below the upper frame 1; one end of the drawn cord 29 and the steering machine 28 The rocker arm is connected, and the other end is connected to the upper end of the imaging mirror 6.

[0087] The steering machine 28 is a power device, mainly including driving motor, reducer, rocker arm and position detecting element, etc., ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com