Automatic sealing type pipe-pipe welding machine head

A welding head and automatic sealing technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of delayed work progress, workers unable to work for a long time, and serious eye damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention are described in detail below, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

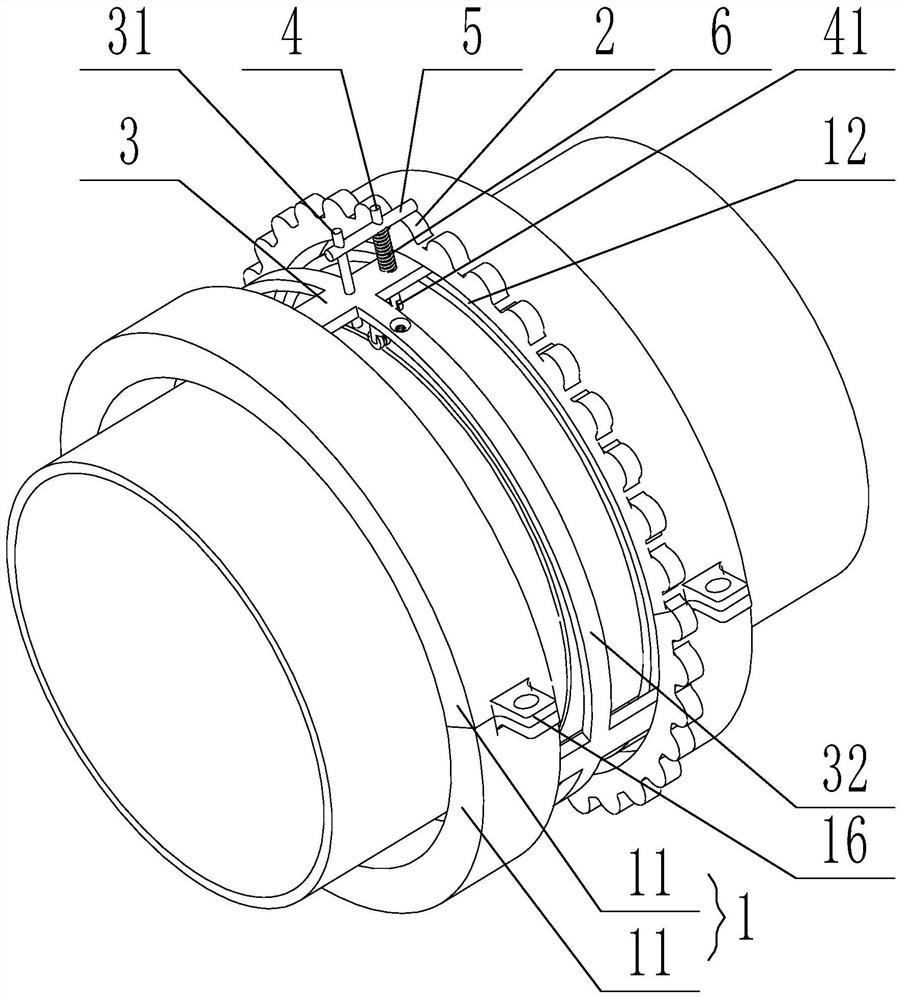

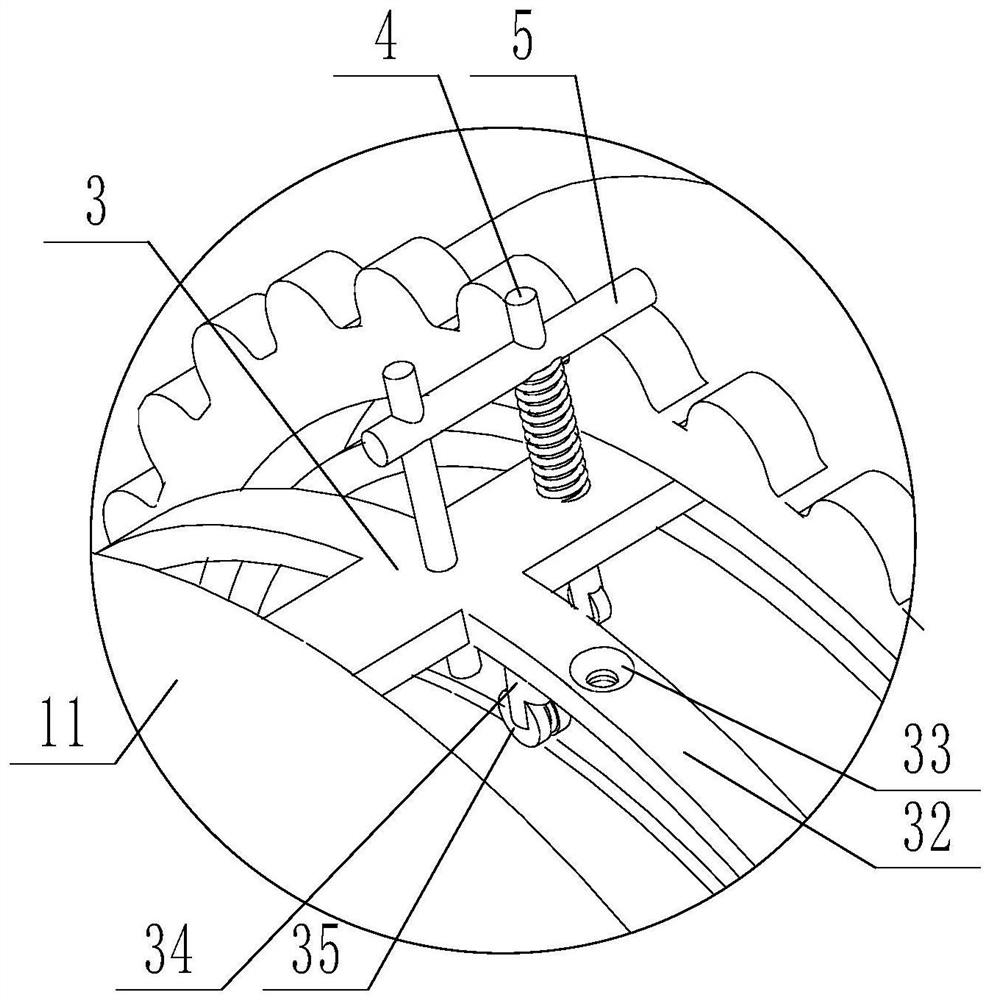

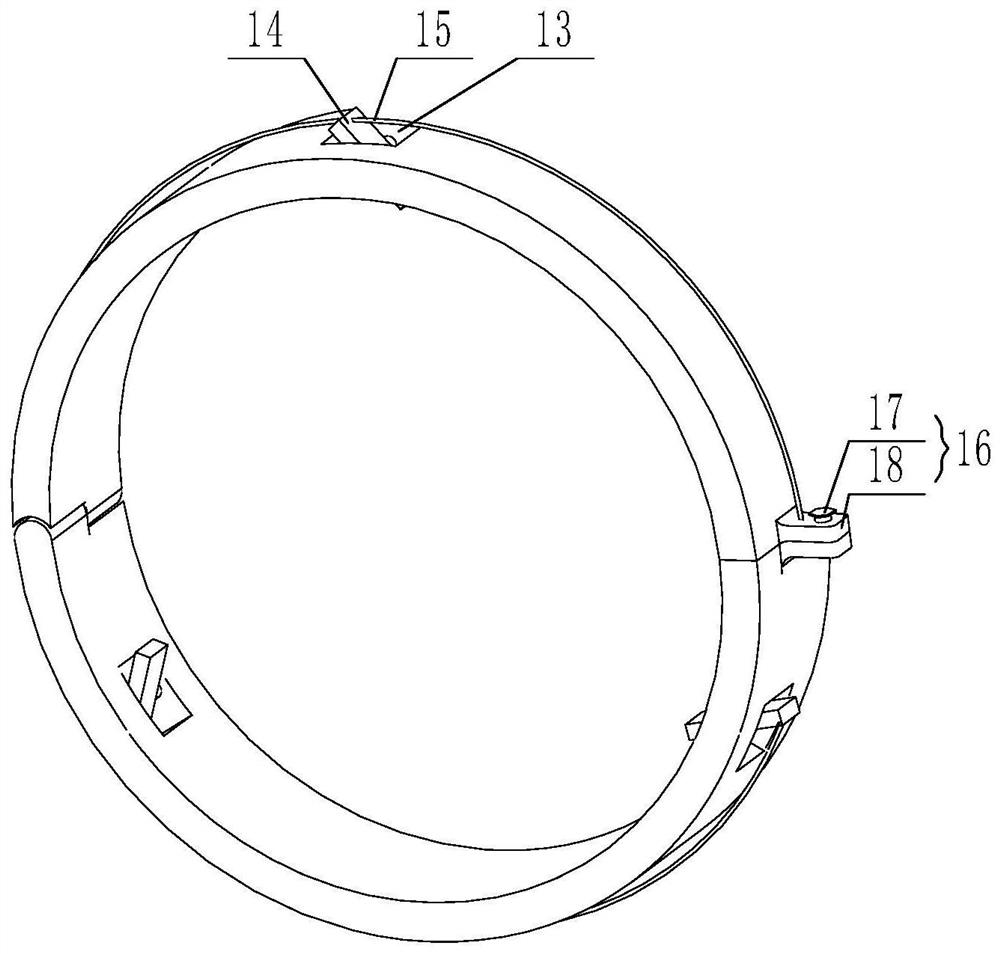

[0029] An automatic sealing pipe welding machine head provided by the present invention comprises: two fixed rings 1, a plurality of half cylinders 2, arc panels 3, vertical bars 4, horizontal bars 5 and tension springs 6; two fixed rings 1 Coaxial left and right, each fixed ring 1 includes two semi-circular rings 11, one end of the two semi-circular rings 11 is hinged, and the other end is fixedly connected by a connector 16; There is an annular groove 12; a plurality of half cylinders 2 are evenly fixed on the outer wall of the right side fixing ring 1 around the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com