Multi-gear rotatable hub power assembly

A powertrain and rotating wheel technology, which is applied in the field of multi-speed rotatable hub powertrains, can solve the problems of inability to meet complex and changeable, single operating conditions, and poor driving flexibility of vehicles with operating requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

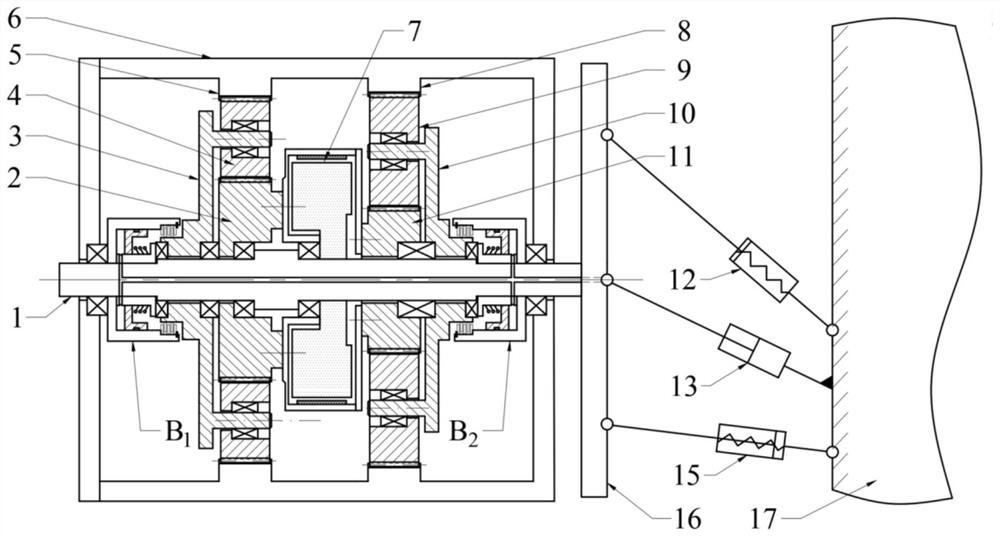

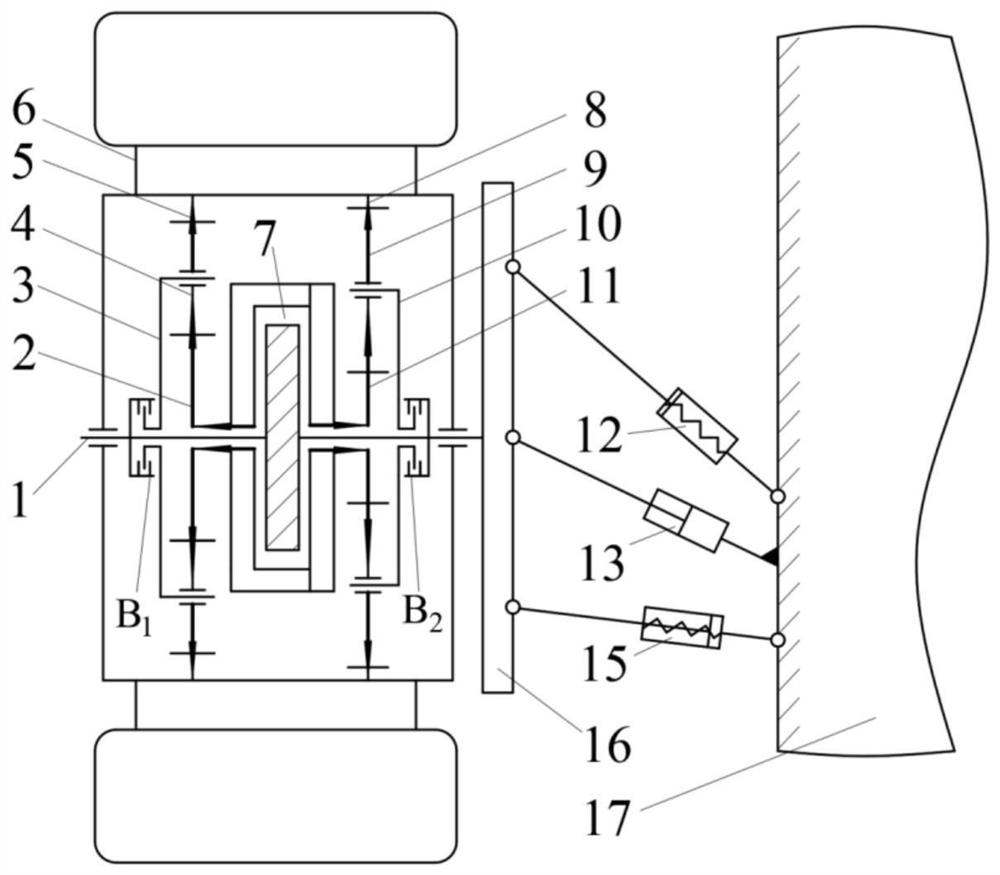

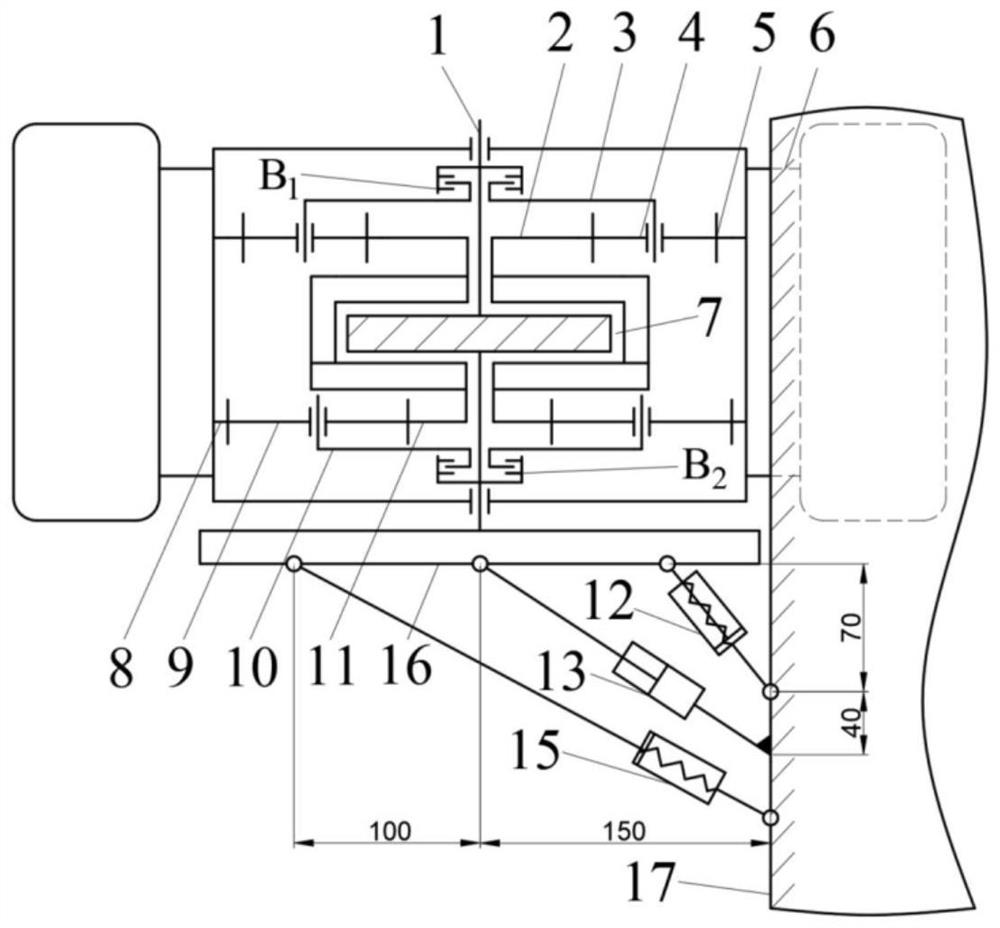

[0026] Example: see figure 1 , a multi-gear rotatable hub power assembly includes a motor 7, two planetary gear trains, electric push rods 12 and 15, supporting piston cylinders 13 and 14, and a first brake B 1 , the second brake B 2 , tire support 16 and vehicle frame 17 are formed.

[0027] For the transmission module, on the one hand, the left end of the rotor of the motor 7 is fixedly connected with the sun gear 2 in the left planetary gear system, and the power is directly transmitted to the sun gear 2, the sun gear 2 and the planetary gear 4 are externally meshed, and the planetary carrier 3 and the planetary gear 4 pass through The bearing forms a revolving pair, the planetary gear 4 meshes internally with the ring gear 5, and the ring gear 5 is fixedly connected inside the hub 6 to output power with a certain transmission ratio; on the other hand, the right end of the rotor of the motor 7 and the sun gear in the right planetary gear 11 is solidly connected, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com