Stilling grid, cleaning method thereof and biological filtration equipment

A biological filtration and stilling technology, applied in biological treatment devices, chemical instruments and methods, biological water/sewage treatment, etc., can solve problems such as the inability to adjust the stilling grid, large loss of filter material, and inconvenient foam discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

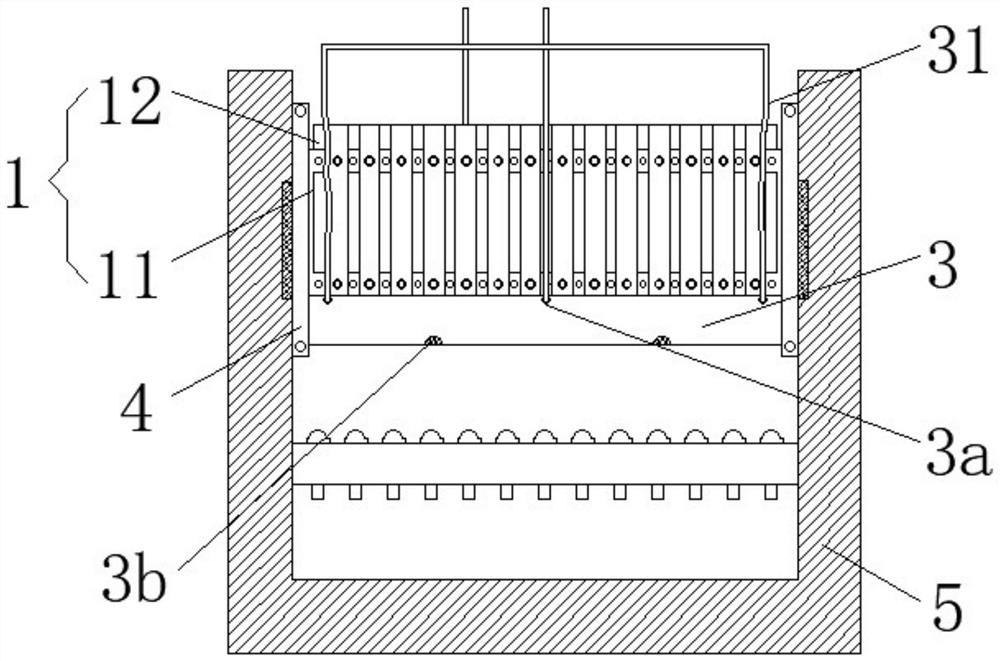

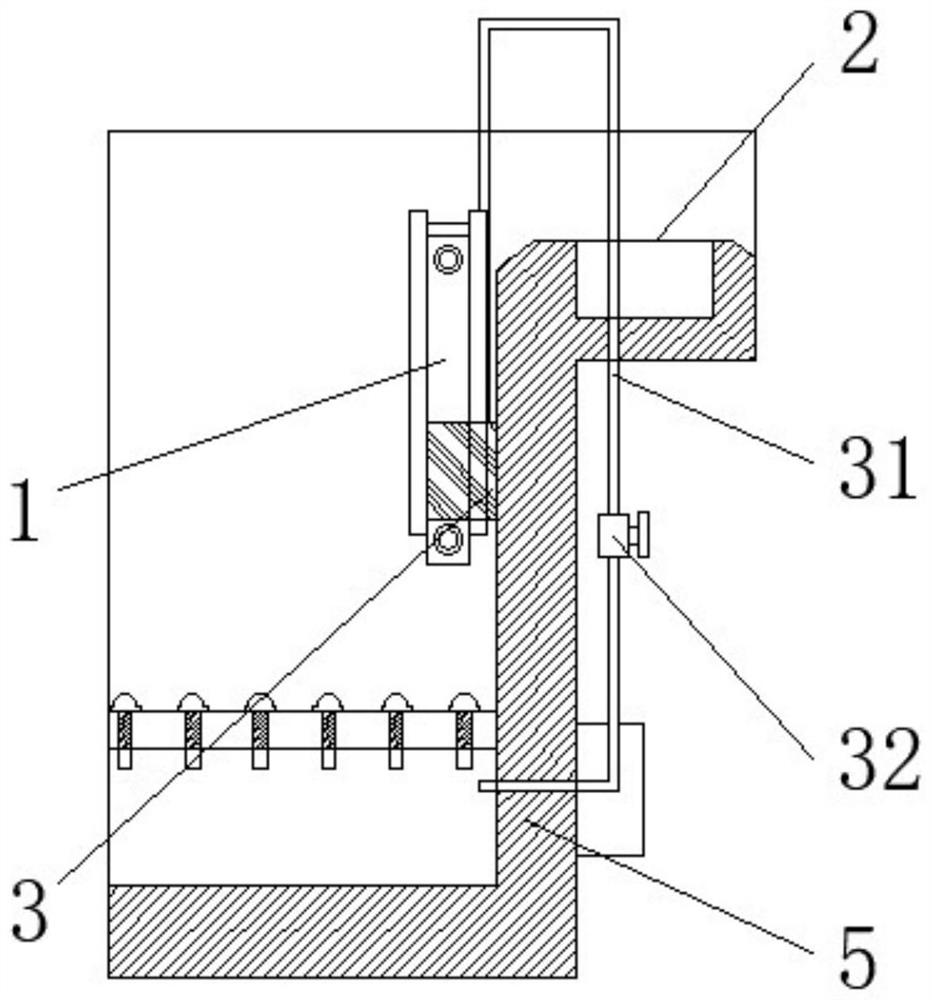

[0059] see Figure 1-3 as well as Image 6 , this embodiment provides a biological filter device. The biological filtration equipment includes a filter tank 5, at least one row of filter heads 6, at least one filter plate corresponding to the at least one row of filter heads 6, at least one water washing pipeline 7, an air source and a stilling grid.

[0060] The filter 5 in this embodiment is a biological filter, which has the advantages of high organic matter volume load, short hydraulic retention time, small footprint, high treatment efficiency, strong impact load resistance, easy film formation, and no secondary sedimentation. Pool and many other advantages, it is a process that can stably and effectively solve the problem of sewage TN and SS exceeding the standard in the current reclaimed water treatment technology.

[0061] There are several filter heads in every row of filter heads 6, which are used to purify the sewage in the filter tank 5. In this embodiment, the n...

Embodiment 2

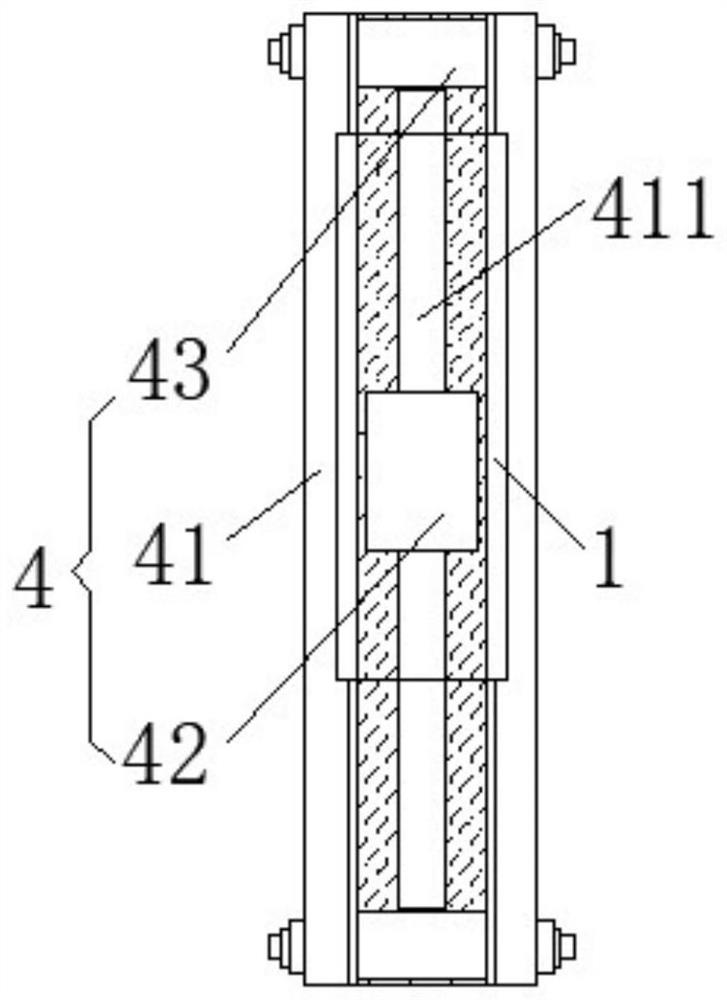

[0084] see Figure 4 The difference between this embodiment and Embodiment 1 is that the moving member 42 includes a pulley 42a and a wheel frame 42b mounted on the pulley 42a. The wheel frame 42b is fixedly connected to the position where the rectangular frame 11 faces the slide rail 41 . The wheel frame 42b is fixed on the rectangular frame 11 to realize the assembly of the pulley 42a in the slide rail 41. When the stilling grid is moved by buoyancy or its own gravity, the pulley 42a moves along the slide rail 41 to assist the lifting of the stilling grid.

Embodiment 3

[0086] see Figure 5 , The difference between this embodiment and Embodiment 1 is that the moving part 42c adopts double flat wheels. The double flat wheels are fixedly connected to the position where the rectangular frame 11 faces the slide rail 41 . The double flat wheels are installed on the rectangular frame 11 and assembled in the slide rail 41, so that when the stilling grid moves under the control of buoyancy or its own gravity, the movement of the double flat wheels assists the lifting of the stilling grid

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com