High-plasticity cold roll forming steel with tensile strength of 500 MPa and production method

A tensile strength and cold-formed technology, applied in the field of high-plasticity cold-formed steel with a tensile strength of 500 MPa and the production field, can solve the problems of increased production cost, low component hit rate, and narrow production process window.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

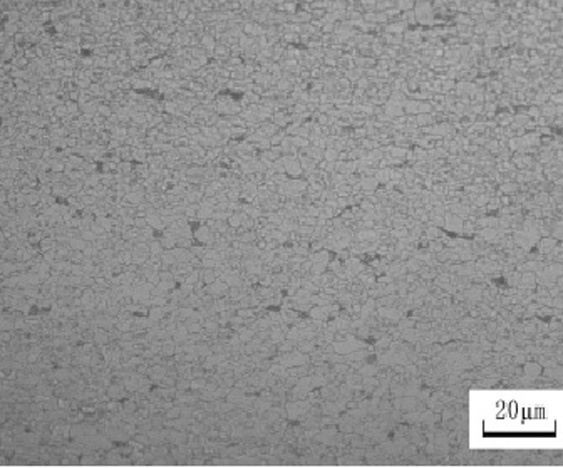

Image

Examples

Embodiment Construction

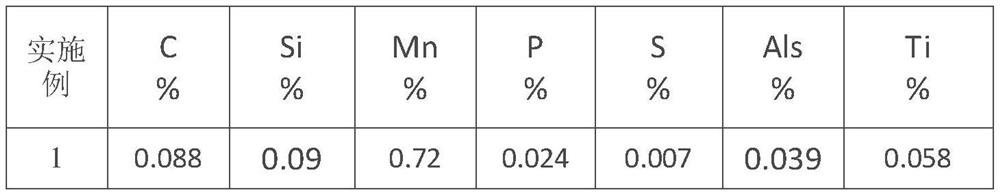

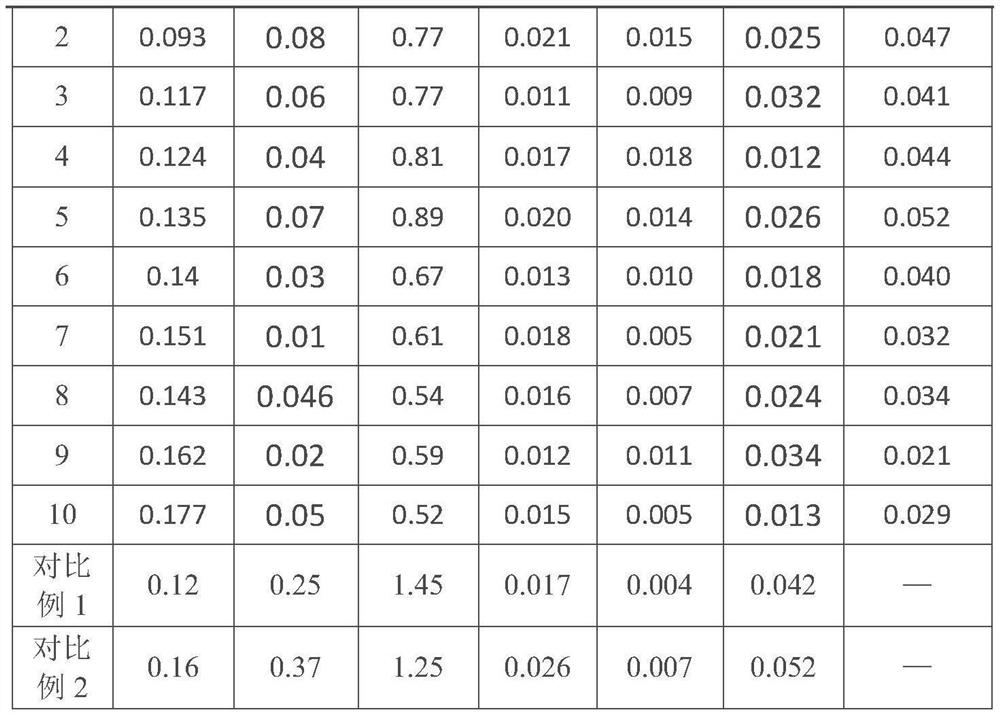

[0037] The present invention is further described below in conjunction with specific embodiment:

[0038] Table 1 is the component value list of each embodiment of the present invention and comparative example;

[0039] Table 2 is the value list of the main process parameters of each embodiment of the present invention and comparative examples;

[0040] Table 3 is a list of performance test results of each embodiment of the present invention and comparative examples.

[0041] Each embodiment of the present invention is produced according to the following steps:

[0042] 1) After smelting in the converter, carry out argon blowing treatment in the tundish, and the argon blowing time should not be less than 5 minutes

[0043] 2) Continuous casting into billets, and control the superheat of molten steel to ≤22°C;

[0044] 3) Heating the slab, and controlling the heating temperature of the slab at 1170-1230°C;

[0045] 3) Carry out rough rolling, and control the exit temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com