Method for correcting overall torsional deformation of beam section of steel box girder

A correction method and technology of bridge sections, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as damage, uneconomical, high bending and torsional rigidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

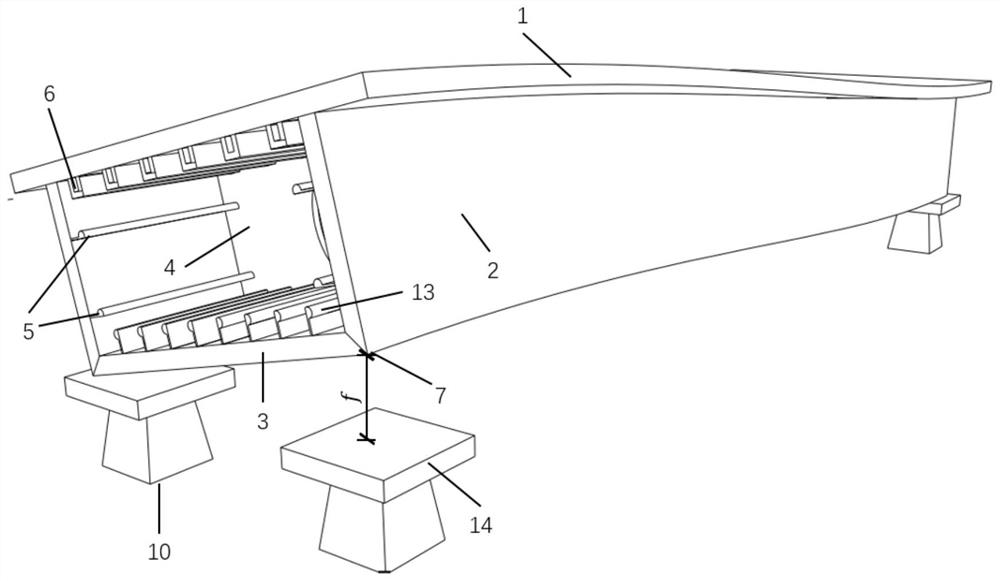

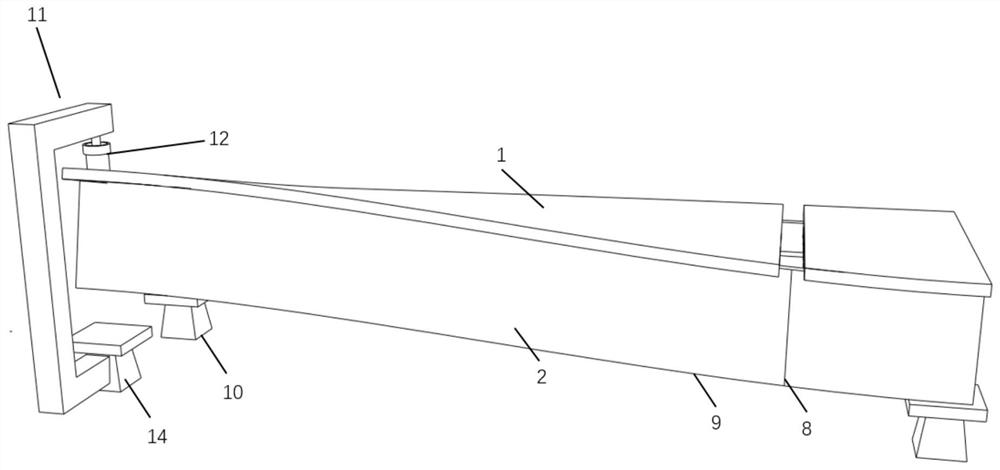

[0053] Such as Figure 1~6 As shown, the length of the beam section is 30m, the beam height is 5m, the distance between the diaphragms 4 is 3m, and the distance between the corner point (suspension) 7 and the fixed support 14 not in contact with the corner point is 240mm.

[0054] Determine the plane position and elevation of the fixed support 10 according to the design coordinates, place the beam section on the fixed support 10, and determine the suspended end of the corner point 7 as the correction end, and the other end as the fixed end.

[0055] Estimated number of revisions

[0056]

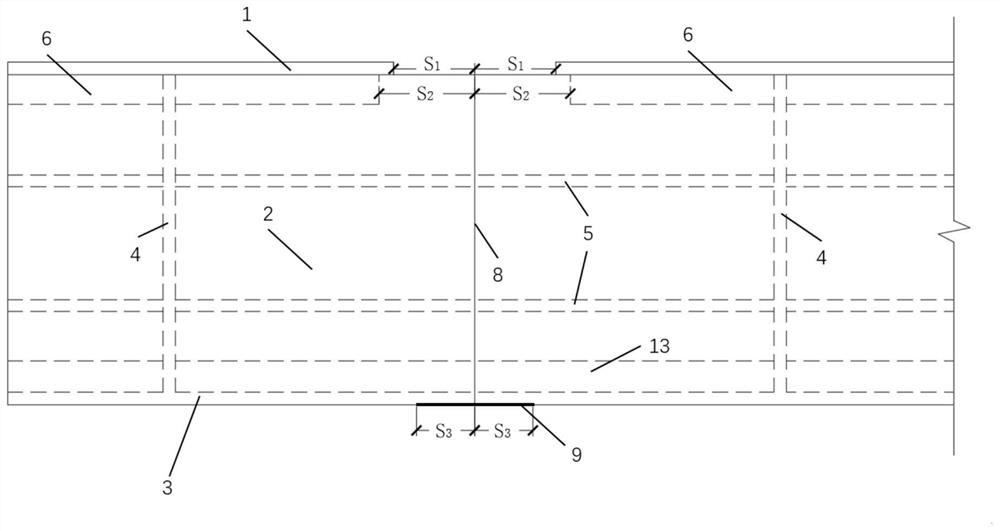

[0057] At the middle point of the bridge deck 1 of the segment closest to the fixed end, cut s symmetrically to both sides along the longitudinal direction 1 = 500mm of bridge deck 1, and s 2 = U-shaped rib 6 of 700mm. The above-mentioned cutting length is only a preferred cutting length of the embodiment of the present application, and the cutting length is not limited thereto, but it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com