Portal frame plate exchange type AGV

An exchange type, gantry technology, which is applied in the building type, buildings where cars are parked, buildings, etc., can solve the problems of complex, inconvenient, and high maintenance cost of transfer and exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

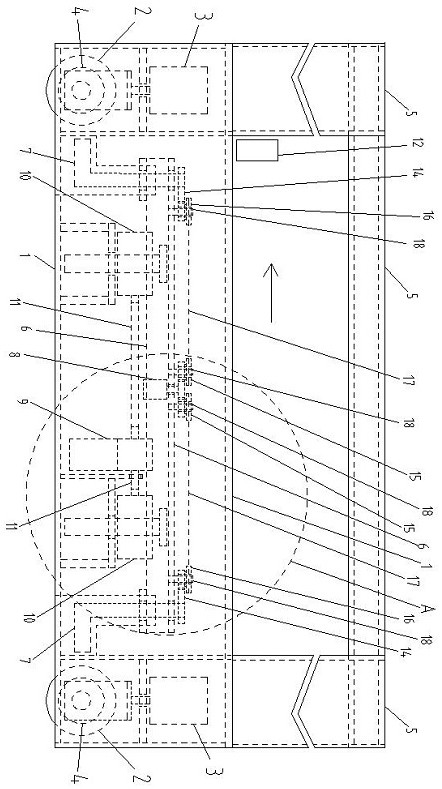

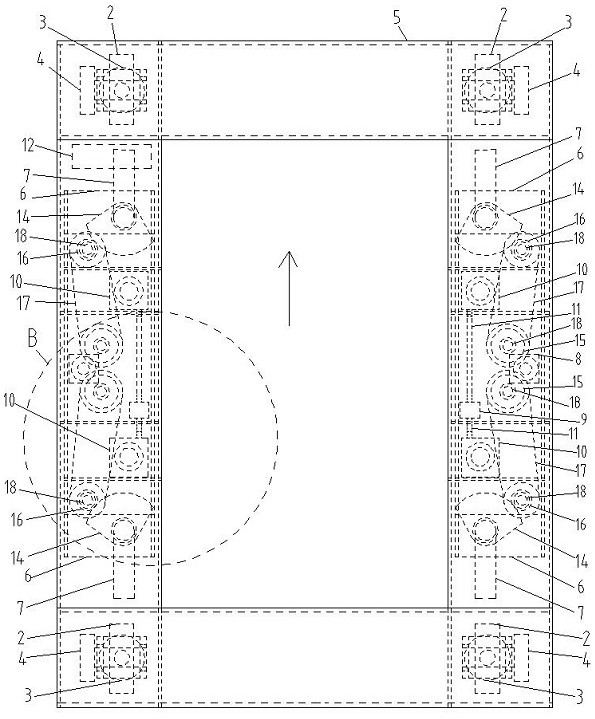

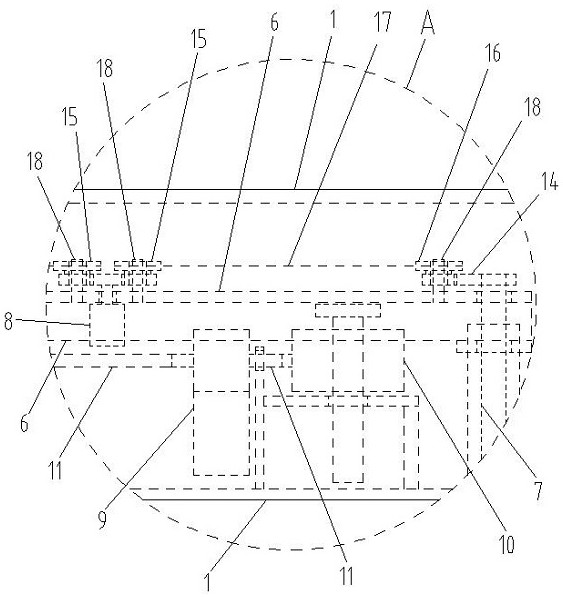

[0015] See attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4, the direction of the arrow is forward. Looking down, the lower ends of the arched structural members 5 are respectively fixed and the strip-shaped box-shaped structural components 1 are arranged symmetrically. 1. The main structure of the front and rear through-type gantry plate exchange type AGV transport vehicle; from the top view and the left view, the four corners of the elongated box-shaped structural component 1 are respectively embedded and fixed with two axial steering wheel assemblies 2; Corresponding positions in the elongated box-type structural assembly 1 are respectively fixedly provided with a lifting motor 9 and a screw lift 10, and the incoming shaft of the screw lifting machine 10 is fixedly connected with the outgoing shaft of the lifting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com