Self-propelled trailing suction offshore ore mining ship

A kind of ore sand and offshore technology, which is applied in mineral mining, earth square drilling, ship accessories, etc., can solve the problems of seabed ore mining equipment mechanization, low degree of automation, shallow mining water depth, and low mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

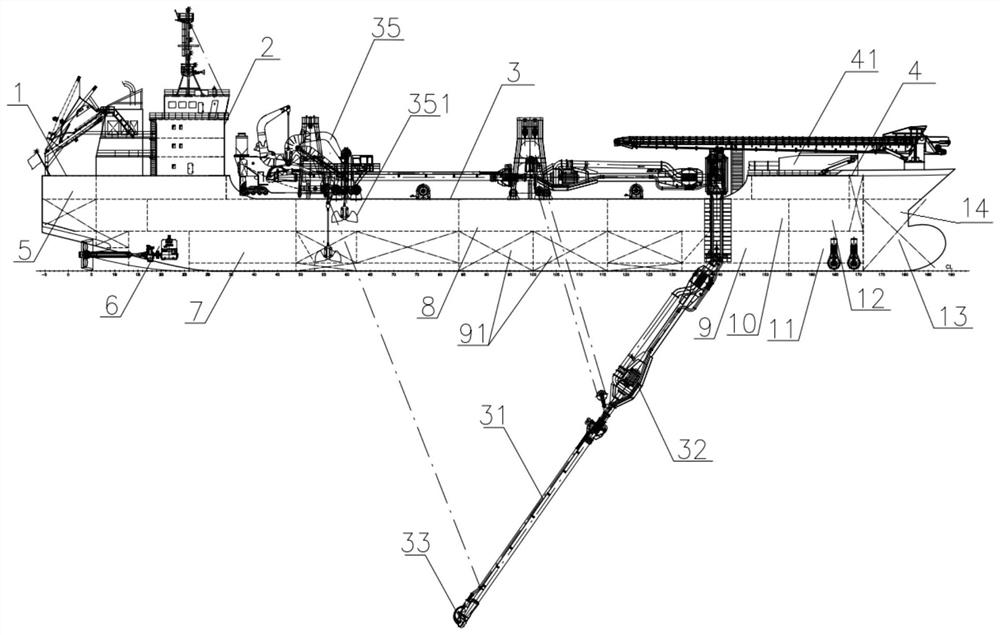

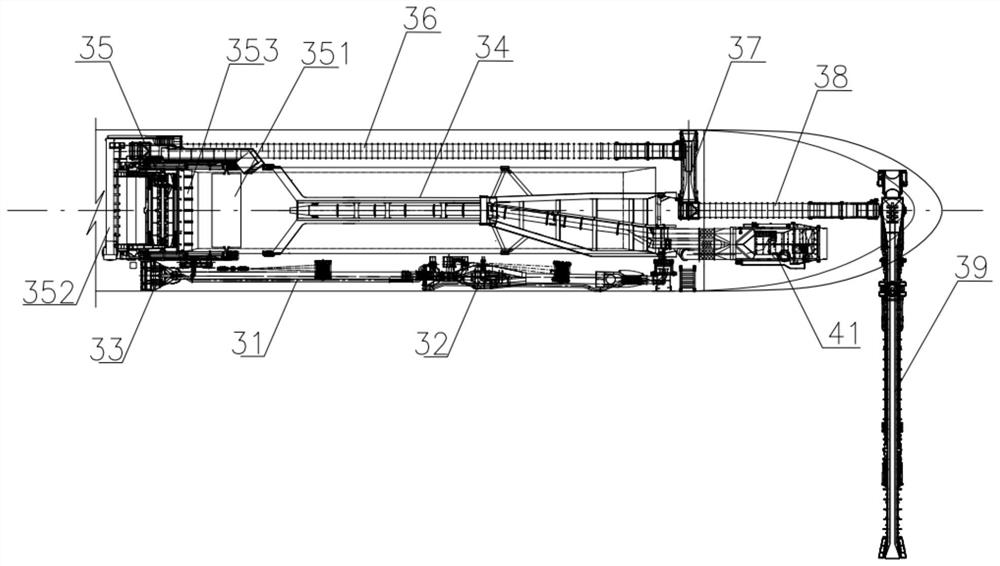

[0028] figure 1 It is the front view of the general layout of the specific embodiment of the self-propelled suction type offshore ore mining ship of the present invention, from the stern above the main deck to the bow, there are stern mooring area 1, stern building and stern deck house 2, and ore loading and unloading operations. Area 3, bow operation and mooring area 4, from the stern below the main deck to the bow are steering gear room 5, propulsion motor room 6, engine room 7, ore tank 8, buoyancy tanks on both sides of the ore tank 9, pump room 10, Spare parts compartment 11, motor compartment 12, electrical equipment room 13, and fore peak compartment 14.

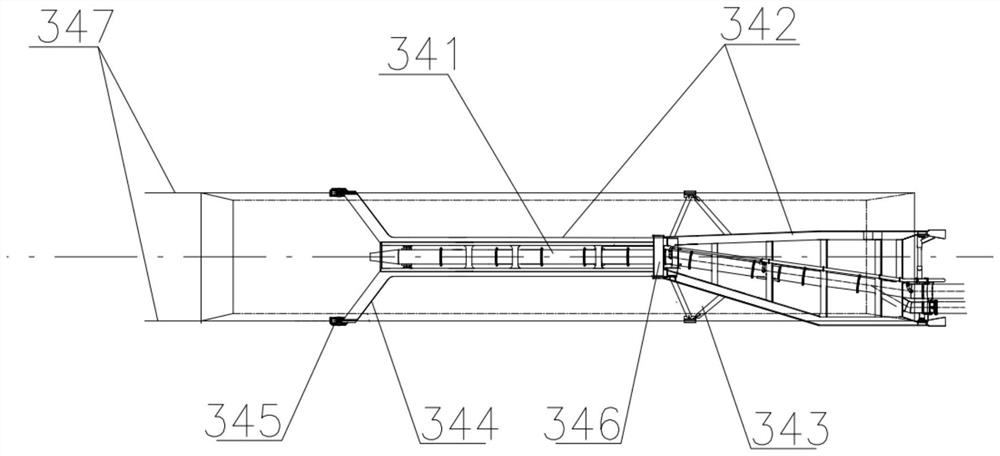

[0029] The starboard side of the main deck of the self-propelled rake-suction offshore ore mining ship of the present invention is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube chief | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap