Desulfurization and denitrification device with dust removal function

A desulfurization, denitrification, functional technology, applied in the field of desulfurization and denitrification, can solve the problems of insufficient cleaning, affecting the working environment, affecting work efficiency, etc., to achieve the effect of improving convenience, keeping clean, and improving cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

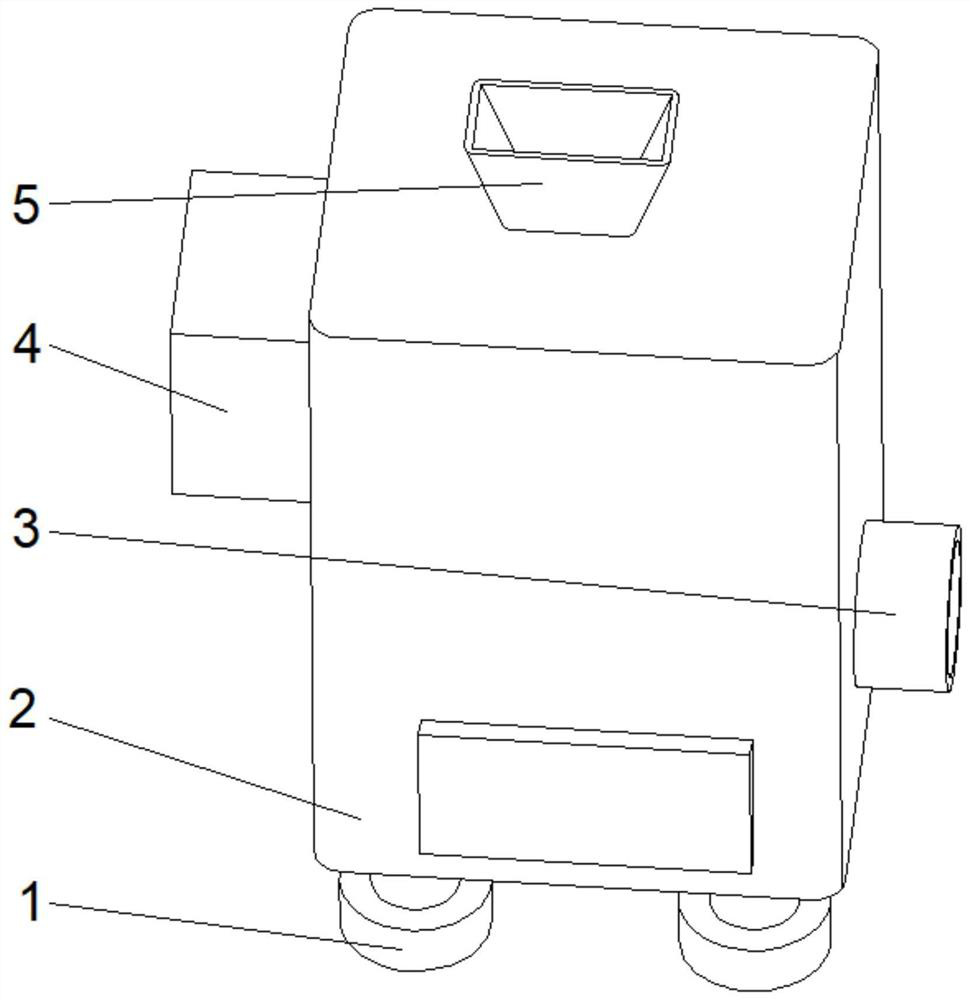

[0033] see Figure 1-2 , the present invention provides a technical solution: a desulfurization and denitrification device with dust removal function, including a support base 1, a desulfurization and denitrification device 2 is fixedly connected to the top of the support base 1, and a desulfurization and denitrification device 2 is provided between the bottom of one side. The inlet 3 and the middle position of the top of the desulfurization and denitrification device 2 are provided with an outlet 5 , and the left top of the desulfurization and denitrification device 2 is fixedly connected with a collection box 4 .

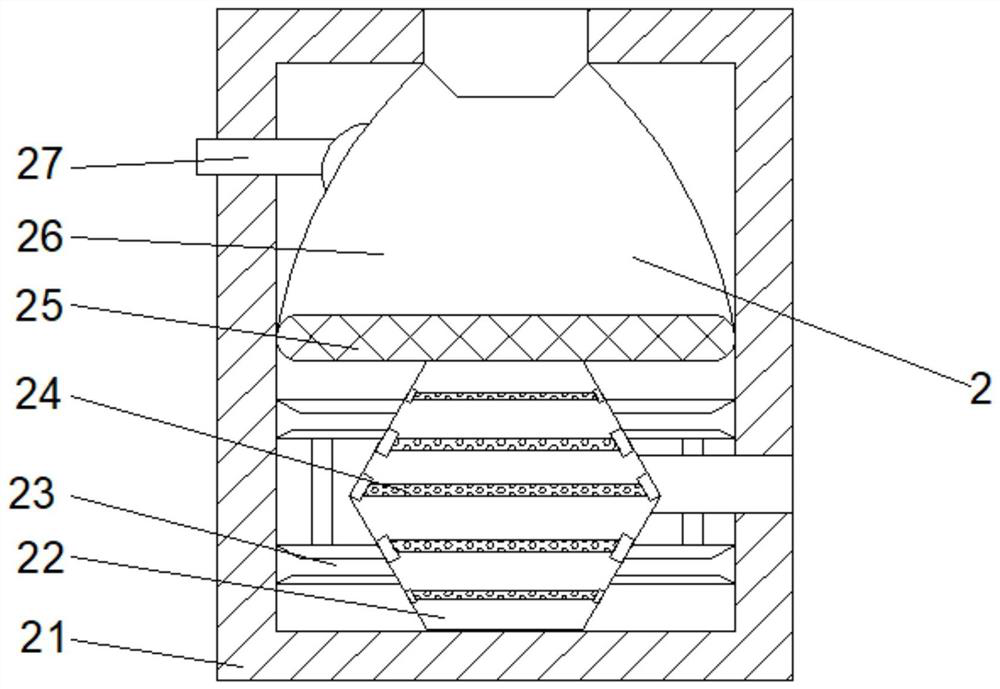

[0034] Wherein, the desulfurization and denitrification device 2 includes a frame 21, a desulfurization and denitrification device 22 is fixedly connected to the middle position of the inner cavity bottom of the frame 21, a return pipe 23 is arranged at the bottom of the inner wall on both sides of the frame 21, and the inner wall on both sides of the desulfurizati...

Embodiment 2

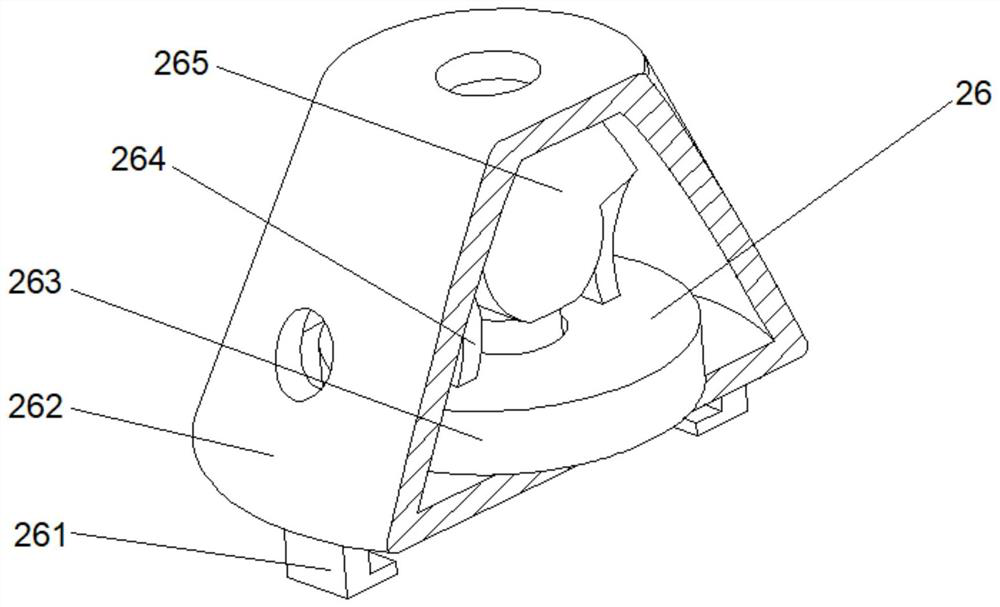

[0037] see Figure 1-4 , On the basis of Embodiment 1, the present invention provides a technical solution: the dust removal mechanism 26 includes a housing 262, the two sides of the bottom of the housing 262 are fixedly connected with clamping blocks 261, and the middle position of the bottom of the inner cavity of the housing 262 is provided with a flange 263 , side plates 264 are fixedly connected to the middle of both sides of the shell 262 , and an intercepting mechanism 265 is fixedly connected to the top of the inner cavity of the shell 262 .

[0038] Among them, the intercepting mechanism 265 includes an auxiliary frame d1, and the two sides of the inner cavity top of the auxiliary frame d1 are provided with flow grooves d2, the middle parts of the inner walls on both sides of the auxiliary frame d2 are fixedly connected to the intercepting plate d3, and the bottoms of the inner walls on both sides of the auxiliary frame d1 are fixedly connected. There is a retracting ...

Embodiment 3

[0041] see Figure 1-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the piston mechanism d7 includes a leakage plate d71, and the middle position of the inner cavity top of the leakage plate d71 is connected with an inlaid pipe d73, and the inlaid pipe d73 The outer surface is fixedly connected with a rubber strip d74, and the top of the inner cavity of the leakage plate d71 is located on both sides of the inlaid pipe d73, and is fixedly connected with an embedded block d72, and the bottom of the leakage plate d71 is provided with a diversion groove d76. The top of the inner cavity is fixedly connected with a vibrating rod d75.

[0042] Wherein, the vibrating rod d75 includes a connecting rod t3, a guide plate t1 is fixedly connected to the top of the connecting rod t3, and hook blocking plates t2 are fixedly connected to both sides of the guide plate t1.

[0043] When in use, the hook block t2 on the surface of the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com