Soldering tin machine capable of recycling soldering tin

A soldering machine and soldering technology, applied in the direction of welding equipment, auxiliary equipment, metal processing equipment, etc., can solve the problems of inconvenient use, high work intensity, and poor practicability, and achieve the effects of convenient use, improved quality, and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

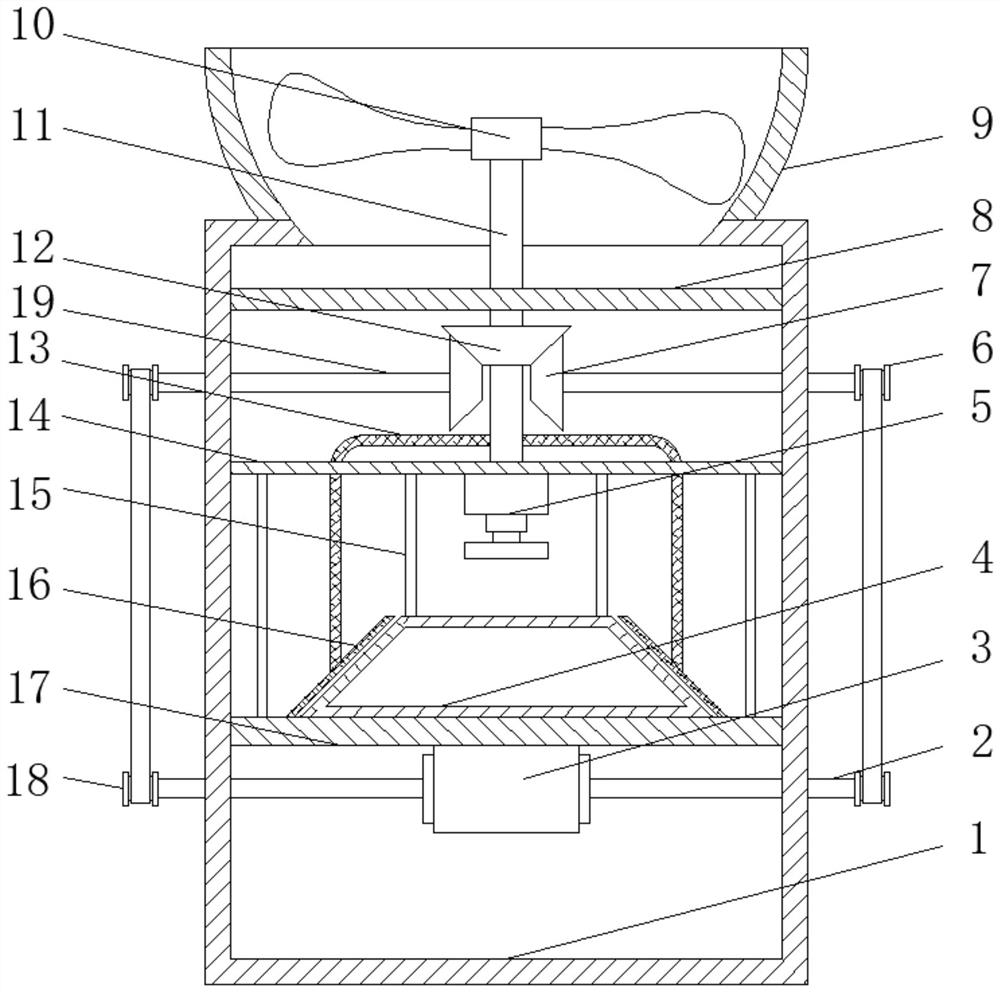

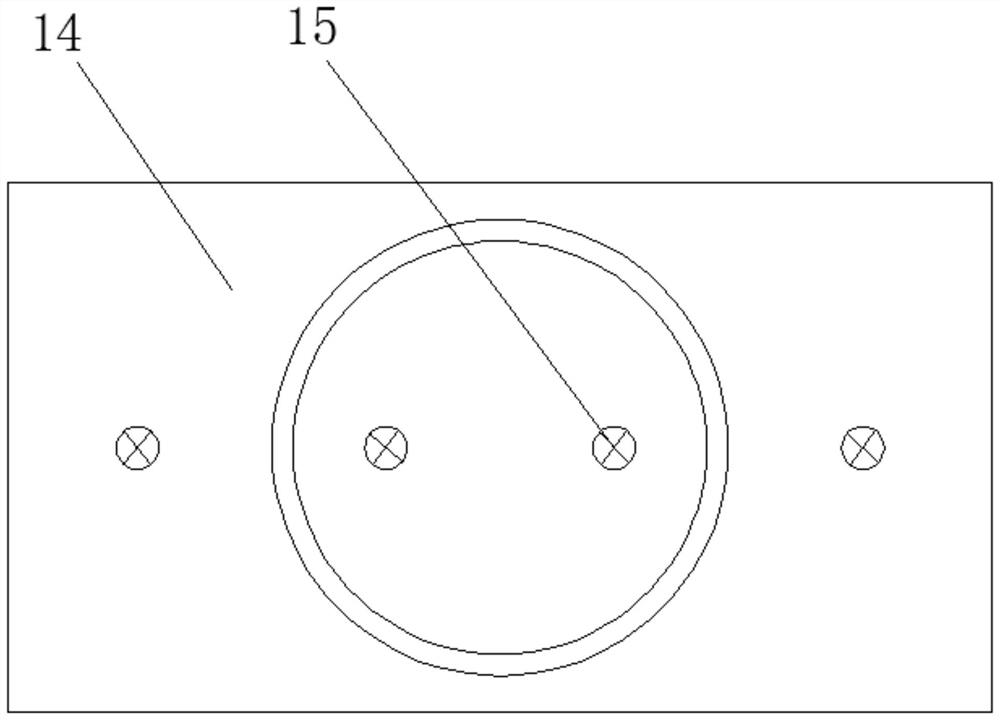

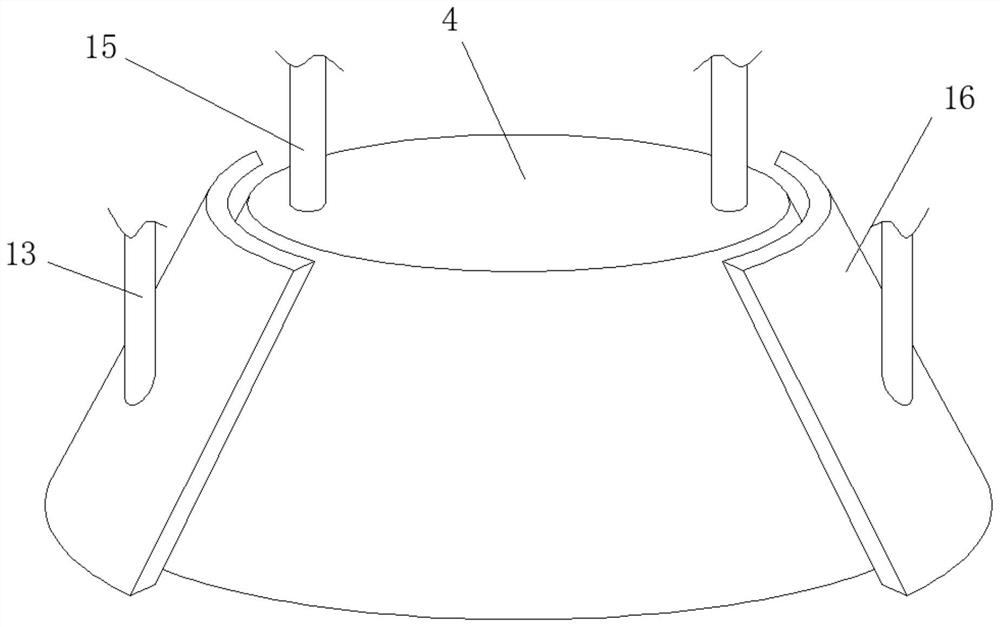

[0025] Embodiment 1: as Figure 1-3 As shown, a soldering machine with recyclable soldering proposed by the present invention includes a box body 1, a support plate 17 is welded to the bottom of the inner wall on both sides of the box body 1, and as a support structure, the bottom of the support plate 17 is fixedly connected with a biaxial motor 3. As a power source to provide power, the output shafts on both sides of the biaxial motor 3 are welded with a shaft 2 that penetrates and extends outside the box 1, and the end of the shaft 2 away from the biaxial motor 3 is welded with a second pulley 18 and a support plate The top of 17 is welded with workbench 4, is convenient to prevent parts, and the top of workbench 4 is welded with support rod 15, and the top of support rod 15 is welded with fixed plate 14, and the bottom of fixed plate 14 is fixedly connected with soldering machine 5;

[0026] The two sides of the fixed plate 14 are welded with the inner walls of both sides o...

Embodiment 2

[0027] Embodiment 2: the top of the box body 1 is welded with a case cover 9, and both sides of the top of the support plate 17 are welded with a stop bar, the top of the stop bar is welded to the bottom of the fixed plate 14, the first bevel gear 7 and the second bevel gear 12 are meshed with each other, the middle part of the fixed plate 14 is provided with a ring hole, the connecting rod 13 passes through the ring hole and is welded with the cleaning plate 16, the two sides of the support plate 17 are provided with slag holes, the material of the cleaning plate 16 is metal, and the double-axis motor The top of 3 is fixedly connected to the top of the support plate 17 by bolts, the model of the biaxial motor 3 is XDF52-B, the top of the soldering machine 5 is fixedly connected to the bottom of the fixing plate 14 by bolts, and the model of the soldering machine 5 is HS375;

[0028] The top of the box body 1 is provided with a smoke outlet, the diameter of the smoke outlet is ...

Embodiment 3

[0029] Embodiment 3: In the present invention, when the device needs to be used, first the workpiece to be processed is placed on the workbench 4 for processing, and the biaxial motor 3 is started during the processing, and the startup of the biaxial motor 3 can drive The output shafts on both sides of it rotate, and the rotation of the output shaft can drive the rotating shaft 2 to rotate, and the rotation of the rotating shaft 2 can drive the second pulley 18 to rotate, and the rotation of the second pulley 18 can drive the first pulley 6 to rotate through the belt. The rotation of a pulley 6 can drive the roller shaft 19 to rotate, and the rotation of the roller shaft 19 can drive the first bevel gear 7 to rotate. Since the first bevel gear 7 and the second bevel gear 12 are meshed with each other, the first bevel gear 7 can rotate. Drive the second bevel gear 12 to rotate, the rotation of the second bevel gear 12 can drive the rotation rod 11 to rotate, the rotation of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com