Automatic pushing-in device for profile frame material

A frame material and profile technology, which is applied in the field of automatic push-in device for profile frame material, can solve the problems of time-consuming and laborious, unstable positioning, flawed cutting accuracy, etc., and achieve the effect of flexible adjustment range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

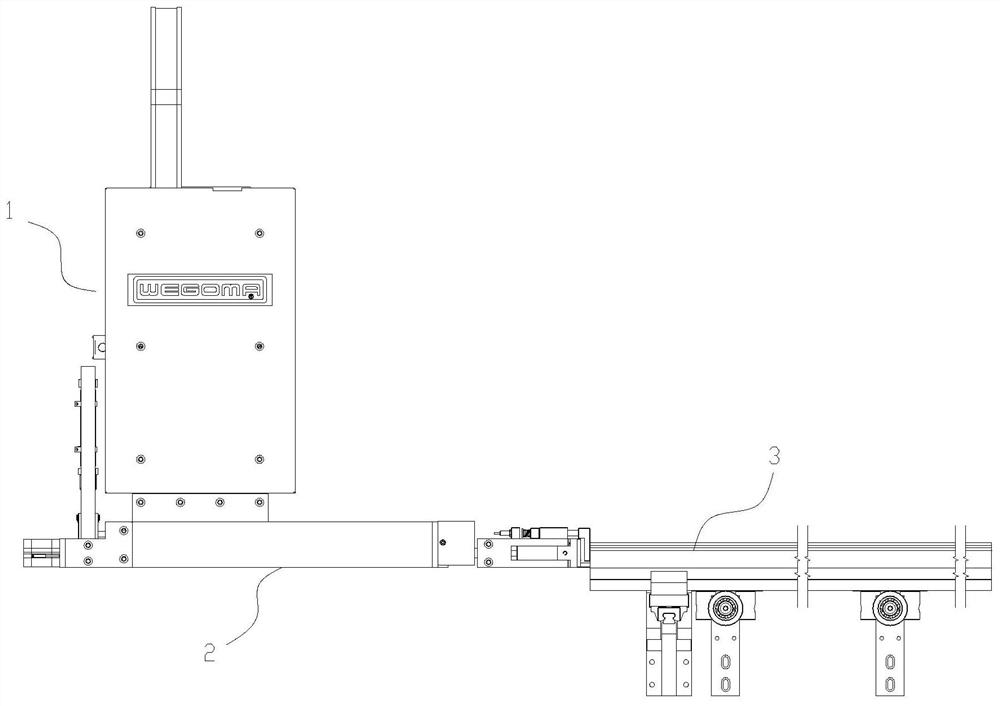

[0056] An automatic push-in device for profile frame materials, combined with a three-axis servo drive power head, can read and identify the CAD data file of the profile cross-section through the control software, automatically calculate the clamping position of the manipulator, and control the automatic clamping of the manipulator clamp. Positioning clamps the profile.

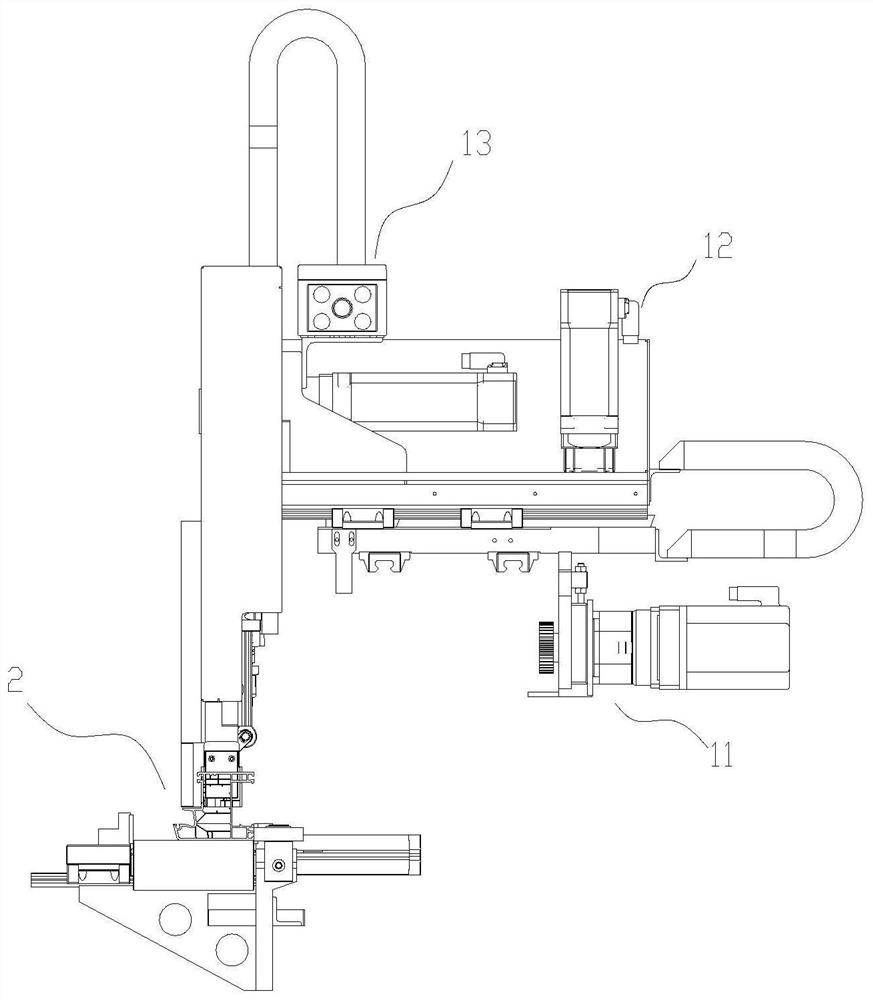

[0057] The three-axis power mechanism 1 includes an X-axis component 11 , a Y-axis component 12 and a Z-axis component 13 , and the X-axis component 11 is configured as an actuator component that provides an effective pushing displacement of the frame material. Specifically, the three-axis servo drive system composed of the X-axis assembly 11, the Y-axis assembly 12, and the Z-axis assembly 13, according to the instructions of the control system, the clamping part of the fully automatic pushing manipulator is positioned at the clamping position of the workpiece, And clamp the workpiece to realize the intellig...

Embodiment 2

[0064] An automatic push-in device for profile frame material, driven by a three-axis power mechanism based on rectangular coordinates, clamped from the end of the frame material and pushed along the length direction of the frame material, the three-axis power mechanism 1 drives the pusher manipulator 2 to generate displacement and push The power of frame material. Through the X-axis assembly 11 , the Y-axis assembly 12 and the Z-axis assembly 13 , the rapid and precise positioning of the clamping position of the pushing manipulator 2 is realized. At the same time, the X-axis assembly 11 is responsible for effectively pushing the workpiece.

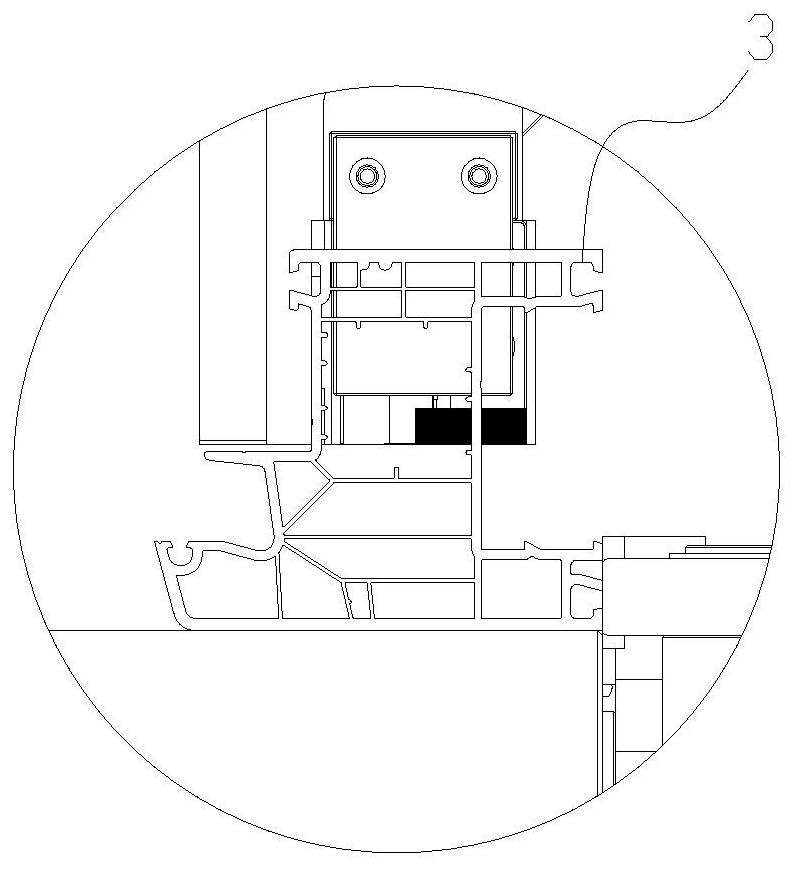

[0065] Specifically, the pushing manipulator 2 includes: a clamping part, a first component, a second component and an induction component.

[0066] The first component provides the driving force for the opening / closing action of the clamping part, while the second component provides the turning power of the clamping part. The sensing c...

Embodiment 3

[0079] This embodiment is the application of a fully automatic material pushing manipulator on the door, window and curtain wall profile processing equipment, and the profile frame material automatic pushing device is used in combination with the material feeding line. The feeding line is a belt-type feeding structure, such as Figure 11 shown. The fully automatic feeding table includes a plurality of conveying belts 4, the frame material 3 (or profile) is placed in parallel on the conveying belts 4, and the conveying belts 4 feed materials along a single direction. At the end of the conveying belt 4 is a row of supporting guide rollers 5, and the frame material 3 is transported to the supporting guiding rollers 5 by the conveying belt 4. The profile frame material automatic push-in device is arranged at the end of the material guide roller 5, and the corresponding processing host is arranged at the end of the material guide roller 5, and the profile frame material automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com