Textured silicon nitride ceramic substrate and cutting method and application thereof

A technology of silicon nitride ceramics and texturing, which is applied in the direction of semiconductor devices, circuits, electrical components, etc., can solve the problems of low thermal conductivity of silicon nitride ceramics and limit the application of electronic component substrates, and achieve high thermal conductivity, The effect of good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

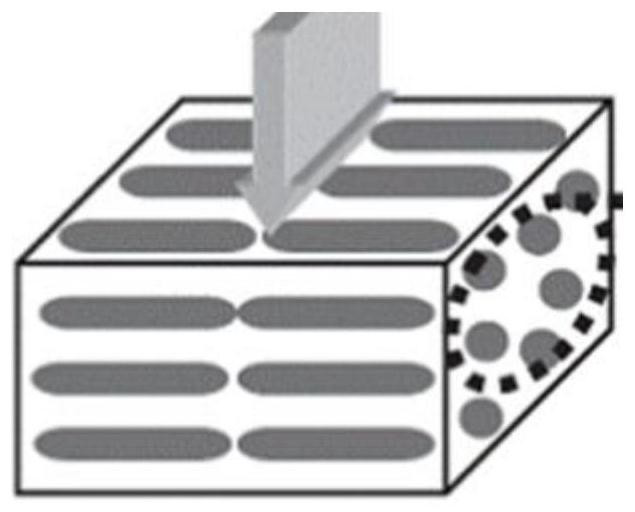

[0036] Using textured silicon nitride ceramics, adjusting its texture direction to be perpendicular to the diamond wire and clamping it on the stage of the electroplated diamond wire saw. Adjust the workpiece feed speed of the electroplated diamond wire saw to 0.08mm / min through the console, and set the wire speed to 30m / s. During the cutting process, it is necessary to keep the stage and the instrument flat, without other vibration effects, and set the tension of the diamond wire of the electroplated diamond wire saw to 27N through pneumatic adjustment. During the cutting process, the diamond wire has a certain swing angle, and the swing angle is 7°. In addition, the diamond of the diamond wire had a mesh number of 300 mesh.

[0037] By the method of Example 1, a total of 100 textured silicon nitride ceramic substrates were prepared, and the thermal conductivity (average value) of the prepared silicon nitride ceramic substrates was 102 W m -1 k -1 , surface roughness (aver...

Embodiment 2

[0039] Using textured silicon nitride ceramics, adjusting its texture direction to be perpendicular to the diamond wire and clamping it on the stage of the electroplated diamond wire saw. Adjust the workpiece feed speed of the electroplated diamond wire saw to 0.10mm / min through the console, and set the wire speed to 30m / s. During the cutting process, it is necessary to keep the stage and the instrument flat, without other vibration effects, and set the tension of the diamond wire of the electroplated diamond wire saw to 27N through pneumatic adjustment. During the cutting process, the diamond wire has a certain swing angle, and the swing angle is 8°. In addition, the diamond mesh of the diamond wire was 350 mesh.

[0040] By the method of Example 2, a total of 100 textured silicon nitride ceramic substrates were prepared, and the thermal conductivity (average value) of the prepared silicon nitride ceramic substrates was 102 W·m -1 k -1 , The surface roughness (average) is ...

Embodiment 3

[0042]Using textured silicon nitride ceramics, adjusting its texture direction to be perpendicular to the diamond wire and clamping it on the stage of the electroplated diamond wire saw. Adjust the workpiece feed speed of the electroplated diamond wire saw to 0.12mm / min through the console, and set the wire speed to 35m / s. During the cutting process, it is necessary to keep the stage and the instrument flat, without other vibration effects, and set the tension of the diamond wire of the electroplated diamond wire saw to 30N by means of pneumatic adjustment. During the cutting process, the diamond wire has a certain swing angle, and the swing angle is 9°. In addition, the diamond of the diamond wire had a mesh number of 400 mesh.

[0043] By the method of Example 3, a total of 100 textured silicon nitride ceramic substrates were prepared, and the thermal conductivity (average value) of the prepared silicon nitride ceramic substrates was 102 W·m -1 k -1 , The surface roughnes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com