A modular channel mechanism

A modular and ducted technology, applied to aircraft parts, power plant types, propellers, etc., can solve problems such as energy component separation and maintenance difficulties, and achieve the effects of reducing energy consumption, reducing duct weight, and prolonging flight time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

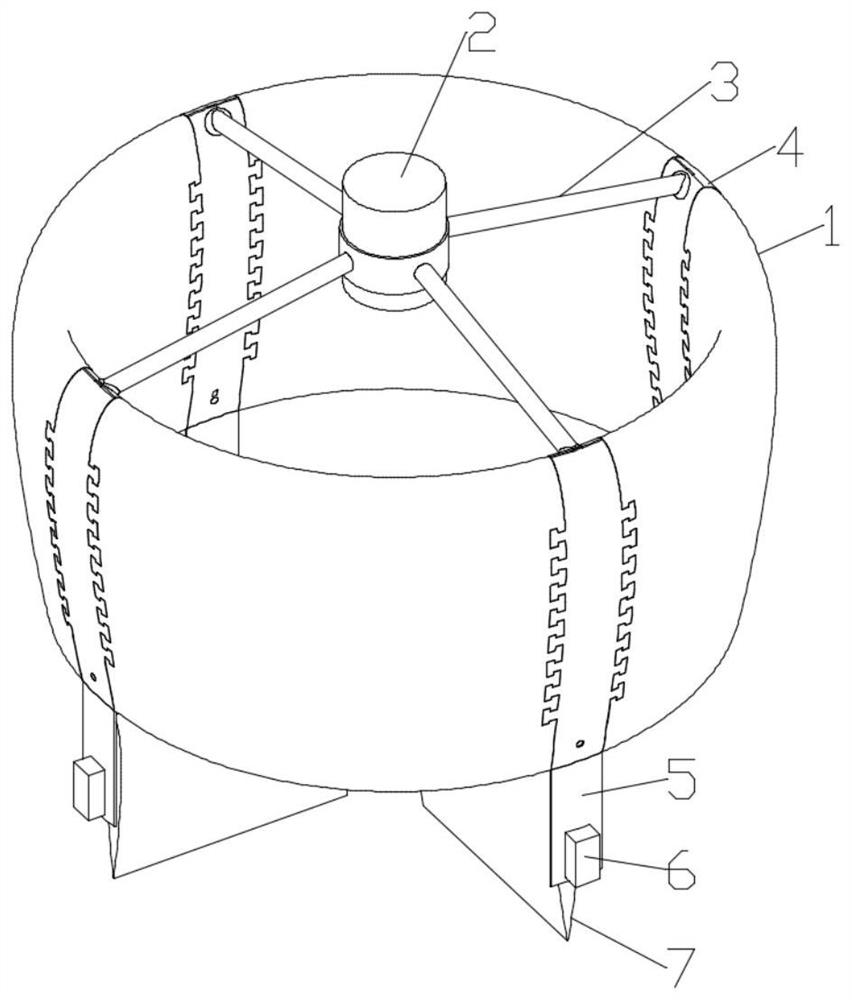

[0034] Such as figure 1 As shown, a modular duct mechanism is disclosed in this embodiment, including a duct housing 1, a motor 2 and a connecting arm 3, wherein the duct housing 1 is in an annular structure, and the motor 2 is located in the duct Inside the casing 1 , and the duct casing 1 and the engine 2 are fixed by a plurality of connecting arms 3 .

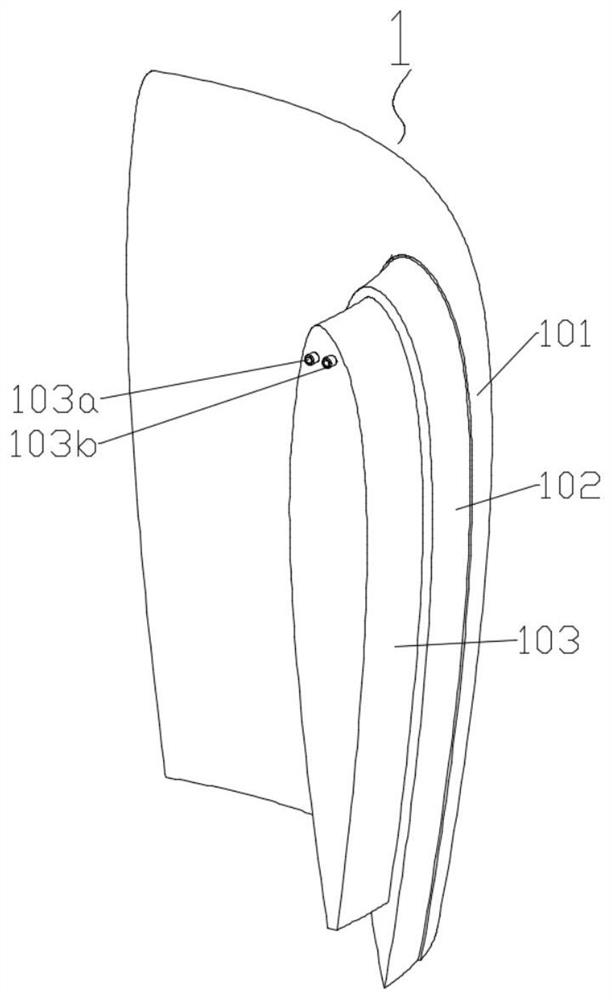

[0035] Specifically, the duct housing 1 includes a plurality of arc-shaped duct bodies 101 and duct connectors 4, the interior of the arc-shaped duct bodies 101 is hollow, and the plurality of arc-shaped duct bodies 101 surround the center of the engine 2 Arranged in a circle, adjacent arc-shaped duct bodies 101 are fixedly connected by duct connectors 4 .

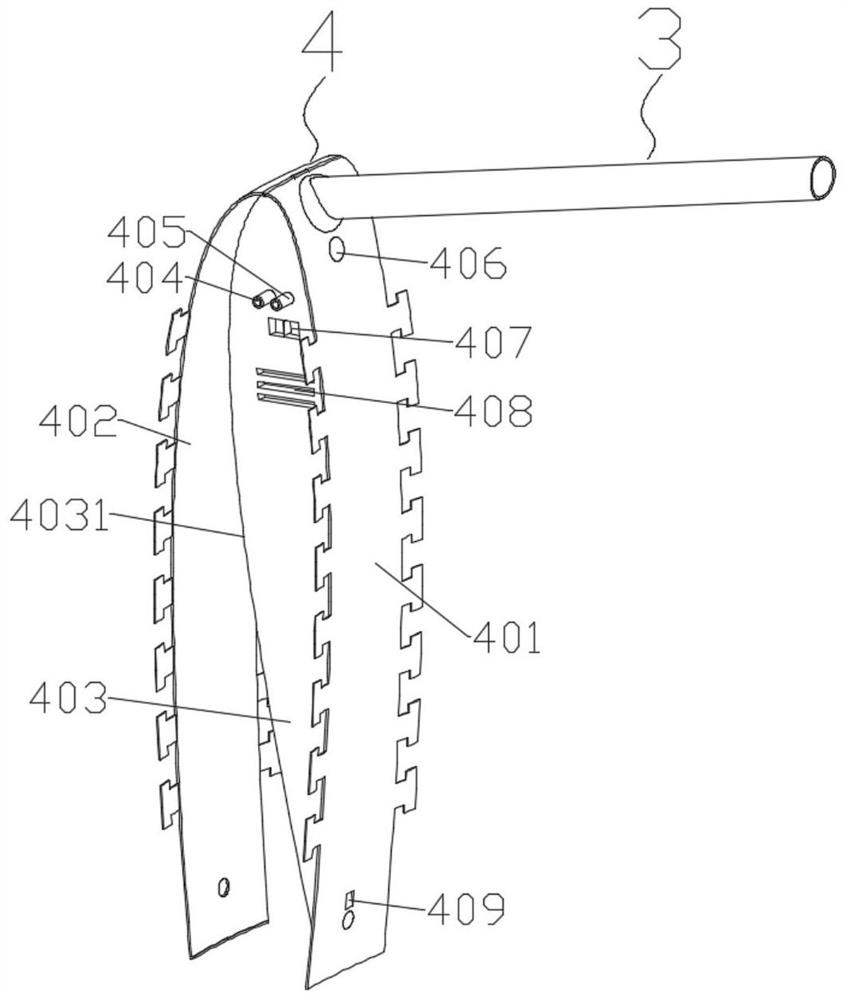

[0036] Such as figure 2As shown, the duct connector 4 includes a movable cover 402, a fixed cover 401 and a fixed part 403, the fixed part 403 is fixedly connected with one end of the connecting arm 3, and the fixed cover 401 and the fixed part 403 The sides are fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com