Health monitoring equipment for hot water energy storage tank

A technology of health monitoring and energy storage tank, which is applied in the measurement, container, packaging and other directions by measuring the frequency change force of the stressed vibrating element, which can solve the problems of unification and achieve the effect of ensuring safe operation and early warning of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

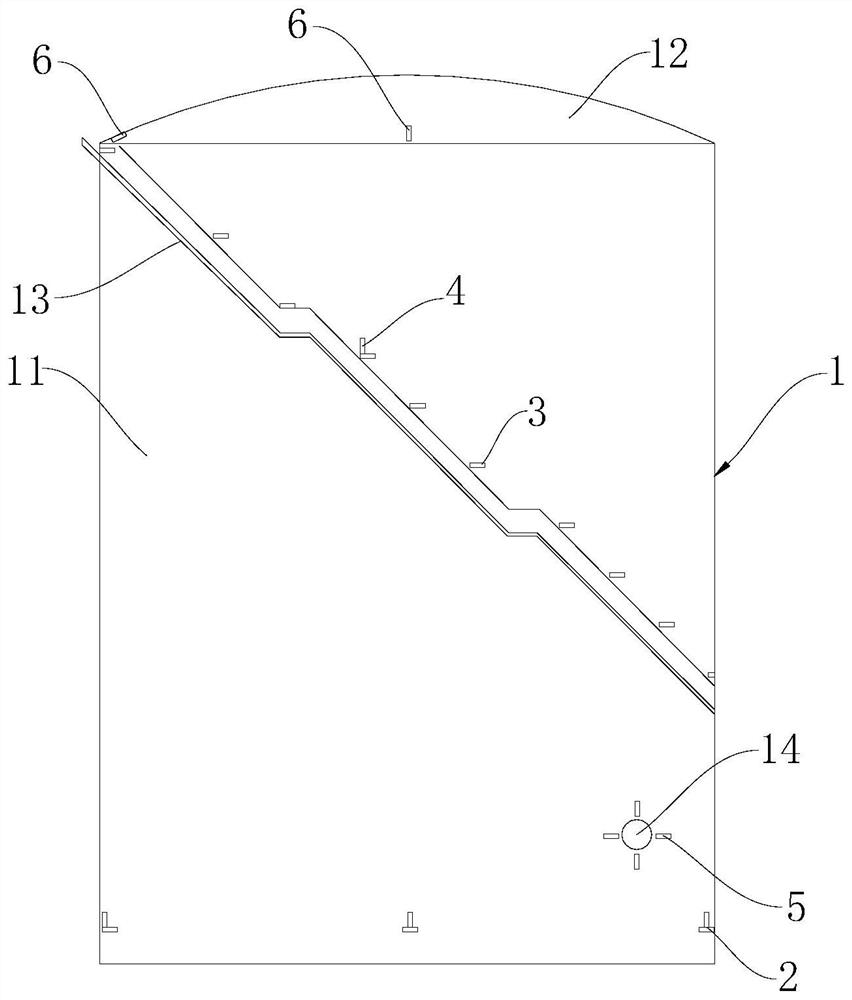

[0023] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

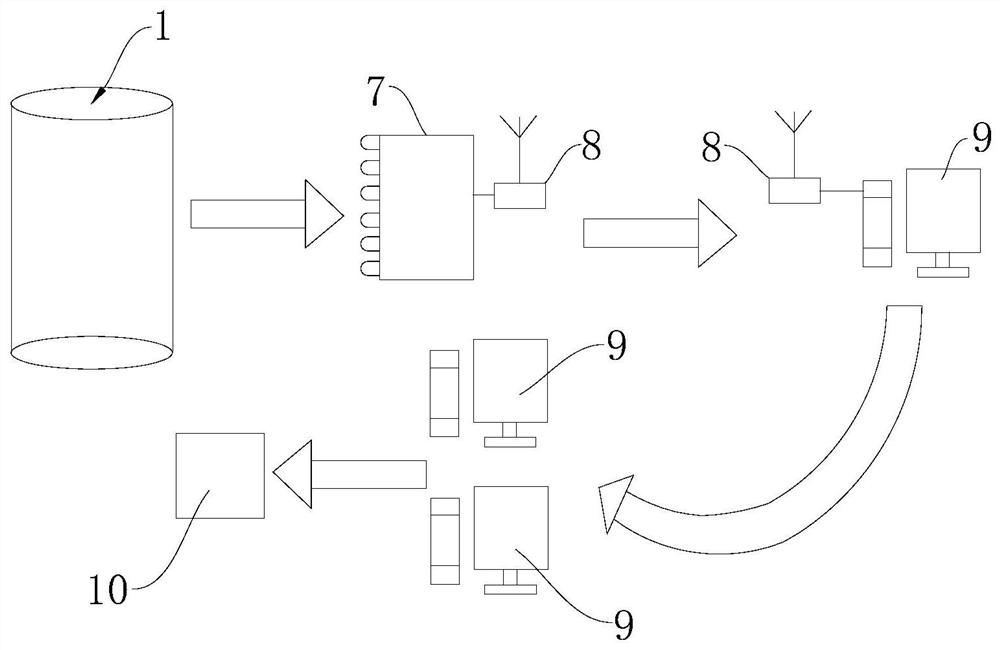

[0024] Combine below figure 1 and figure 2 A hot water storage tank health monitoring device according to an embodiment of the present invention is described.

[0025] The hot water energy storage tank health monitoring device according to the embodiment of the present invention includes a hot water energy storage tank 1 , a vibrating wire sensor and a data acquisition instrument 7 . There are multiple vibrating wire sensors, and the multiple vibrating wire sensors are fixed on the outer surface of the hot water energy storage tank 1 . Each of the plurality of vibrating wire sensors is connected to a data acquisition instrument 7 .

[0026] Specifically, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com