Production process of 8630MOD3-85K forge piece for deep sea wellhead casing hanger

A production process and casing technology, which is applied in the field of 8630MOD3-85K forgings for deep-sea wellhead casings, can solve the problems of inability to meet the application requirements of deep-sea forgings, poor low-temperature impact toughness, and low local strength, so as to optimize the heat treatment process and improve Hardness and wear resistance, the effect of optimizing the forging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

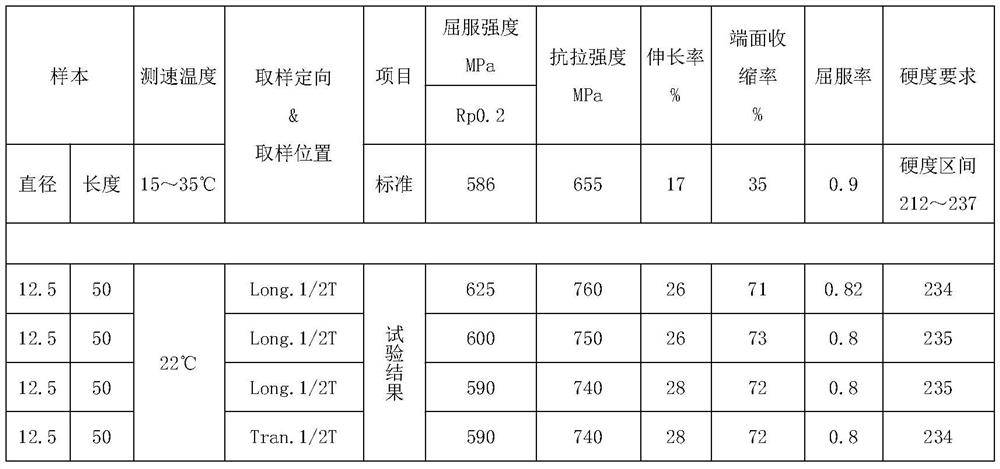

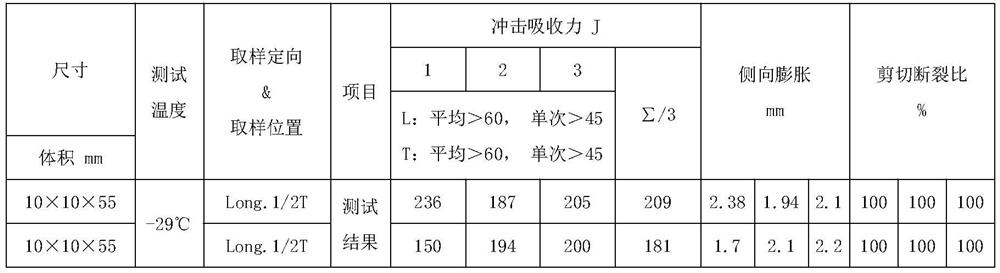

Embodiment 1

[0019] The production process of the 8630MOD3-85K forging used for deep-sea wellhead casing hanging of the present invention, its production steps are as follows:

[0020] The chemical composition is: C: 0.25~0.33%; Si: 0.15~0.35%; Mn: 0.7~1.1%; P: ≤0.015%; S: ≤0.01%; Cr: 0.85~1%; Ni: 0.75~0.99 %; Mo:0.35~0.45%; Cu:≤0.25%; Ti:≤0.025%; Bi:≤0.01%; N:≤0.012%; Nb:≤0.01%; Al:0.02~0.035%; Sn:≤0.015 %; V:0.002~0.03%; B:≤0.0005%; Pb:≤0.01%; As:≤0.02%; Sb:≤0.02%; H:≤1.6ppm; O:≤25ppm; The rest is Fe, and steel billets with a DI value greater than 8.0 are raw materials;

[0021] Preheat the billet first. After the preheating is completed, put the billet into the forging furnace for heating. When the temperature of the billet reaches the initial forging temperature, carry out constant temperature and heat preservation. The heat preservation time is 0.5h / inch to 1.5h / inch (inch is the maximum Wall thickness dimension) calculation, and then use the WHF forging method and FM forging method...

Embodiment 2

[0025] The percentage by weight of the chemical composition is: C: 0.29-0.33%; Si: 0.15-0.35%; Mn: 0.89-1.1%; P: ≤0.015%; S: ≤0.01%; Cr: 0.9-1%; Ni: 0.75~0.99%; Mo:0.35~0.42%; Cu:≤0.25%; Ti:≤0.025%; Bi:≤0.01%; N:≤0.012%; :≤0.015%;V:0.002~0.03%;B:≤0.0005%;Pb:≤0.01%;As:≤0.02%;Sb:≤0.02%;H:≤1.6ppm;O:≤25ppm;CE:< 0.833%, the rest is Fe, the steel billet with DI value greater than 8.0 is the raw material;

[0026] Preheat the billet first. After the preheating is completed, put the billet into the forging furnace for heating. When the temperature of the billet reaches the initial forging temperature, carry out constant temperature and heat preservation. The heat preservation time is 0.5h / inch to 1.5h / inch (inch is the maximum Wall thickness dimension) calculation, and then use the WHF forging method and FM forging method to repeatedly upsetting and drawing the steel billet three times in the horizontal and vertical directions, so that the steel billet is forged into a casing hanging f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com