Smoke and steam pollution treatment and waste heat recovery comprehensive reutilization system in catering industry

A pollution control and waste heat recovery technology, applied in air conditioning systems, ventilation systems, applications, etc., can solve environmental pollution and other problems, achieve the effects of reducing atmospheric environmental pollution, saving operating costs and labor costs, and reducing exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

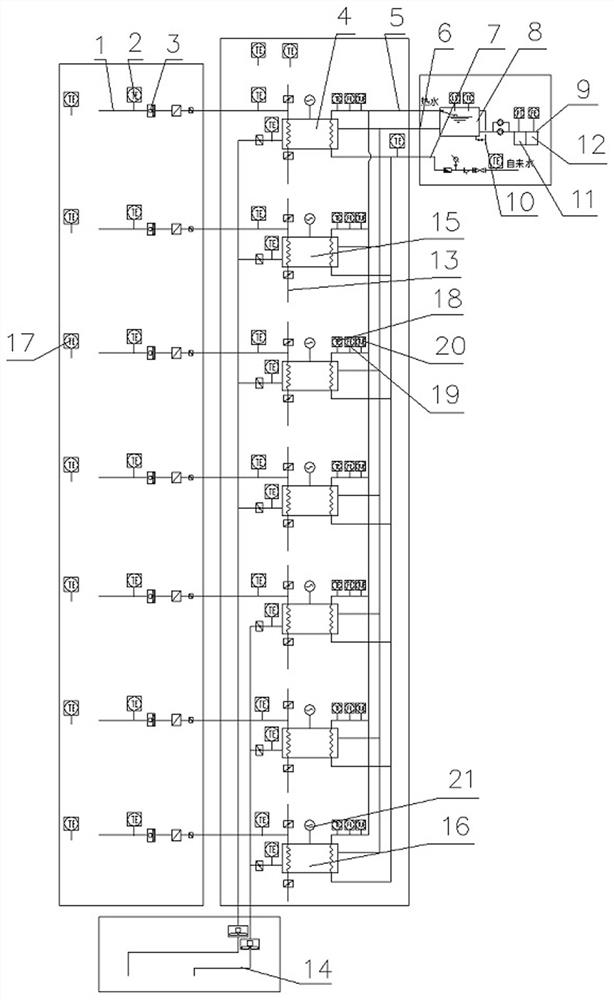

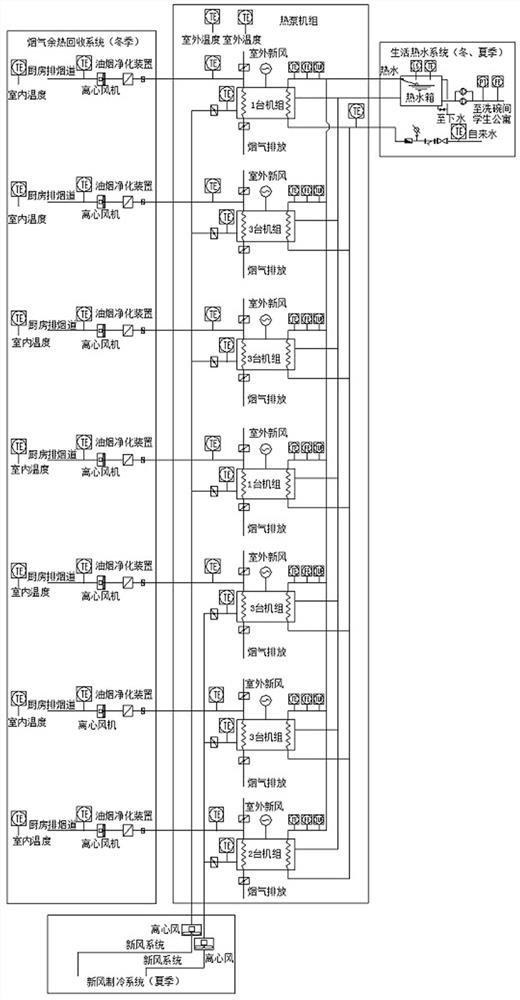

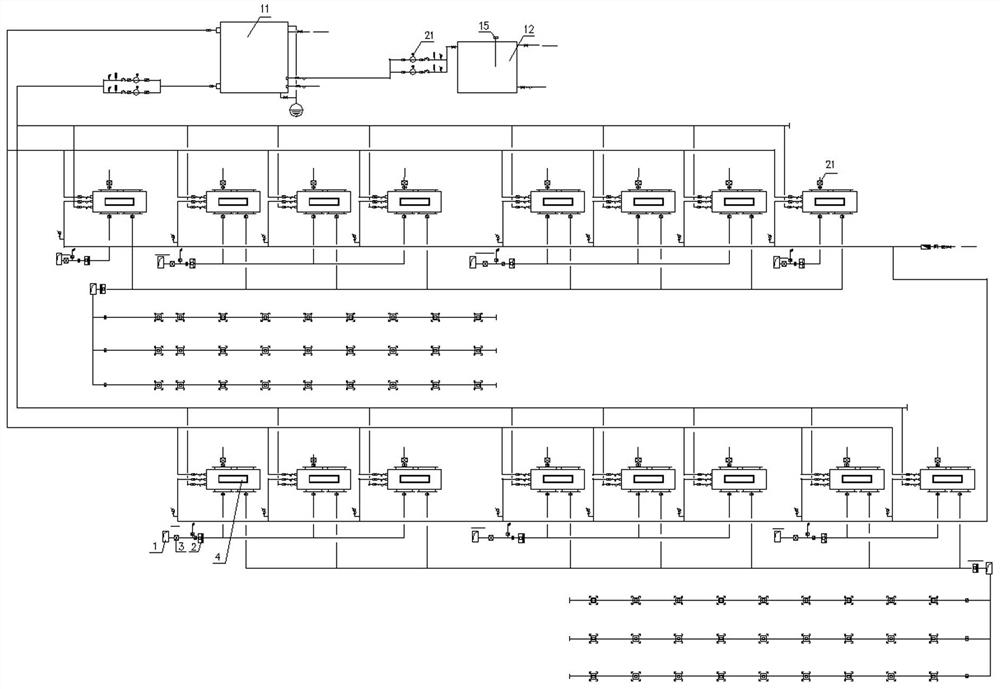

[0039] A comprehensive reuse system for the treatment of smoke and steam pollution in the catering industry and waste heat recovery, which comprises: a kitchen exhaust duct 1, the kitchen exhaust duct is connected to a centrifugal fan 2, and the centrifugal fan is connected to an electrostatic oil fume purifier 3 , the electrostatic oil fume purifier is connected to a unit 4, the unit is connected to a hot water pipe 5, a flue gas circulation pipe 6, and a tap water pipe 7, and the hot water pipe communicates with the flue gas The pipes are all connected to the canteen hot water tank 8, the canteen hot water tank is connected to the hot water use pipe 9 and the sewer pipe 10, the hot water use pipe is connected to the dishwashing room 11 and the apartment hot water tank 12, and the 1 The unit is connected to the purification flue gas discharge pipe 13 and the fresh air system 14.

[0040] The kitchen exhaust duct, centrifugal fan, and electrostatic oil fume purifier are the ex...

Embodiment 2

[0046] In the catering industry smoke and steam pollution control and waste heat recovery comprehensive reuse system described in Example 1, the fresh air system, the tap water pipe, and the hot water pipe are all connected to a group of 3 units 15, and the The three units are connected to the purified flue gas discharge pipe, the three units are connected to the electrostatic oil fume purifier, the electrostatic oil fume purifier is connected to the centrifugal fan, and the centrifugal fan is connected to The kitchen flue as described.

Embodiment 3

[0048] In the catering industry smoke and steam pollution control and waste heat recovery comprehensive reuse system described in Example 1, the fresh air system, the tap water pipe, and the hot water pipe are all connected to one unit, and the one unit Connect the purification flue gas discharge pipe, and connect the one unit to the electrostatic oil fume purifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com