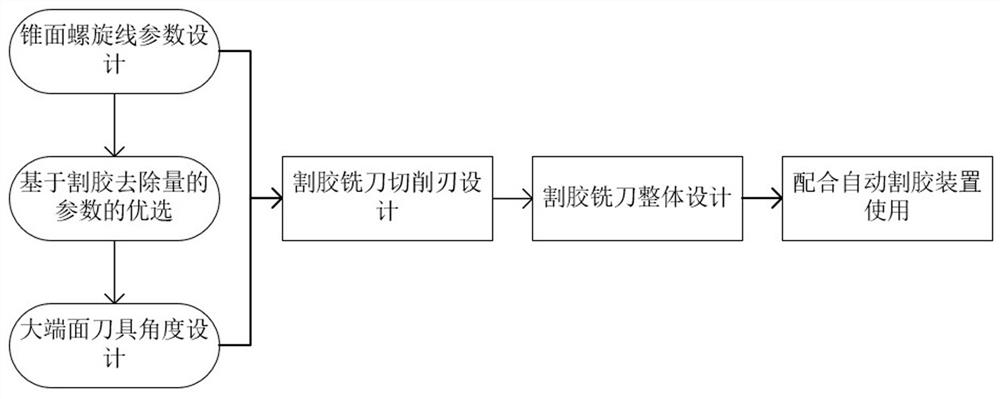

A special high-speed integral rubber tapping tool design method

A tool design, integrated technology, applied in the field of special rubber tapping tool design, can solve the problems of not being able to process the drainage groove at the same time, blocking the rubber tree latex tube, and the wood chips cannot be discharged smoothly. The effect of finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

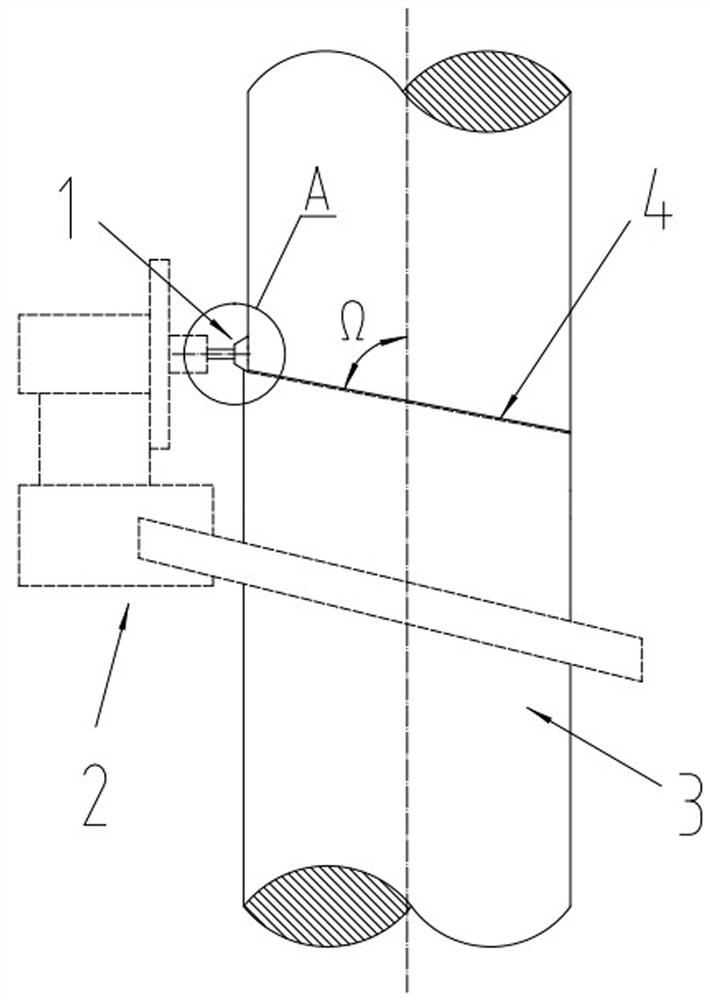

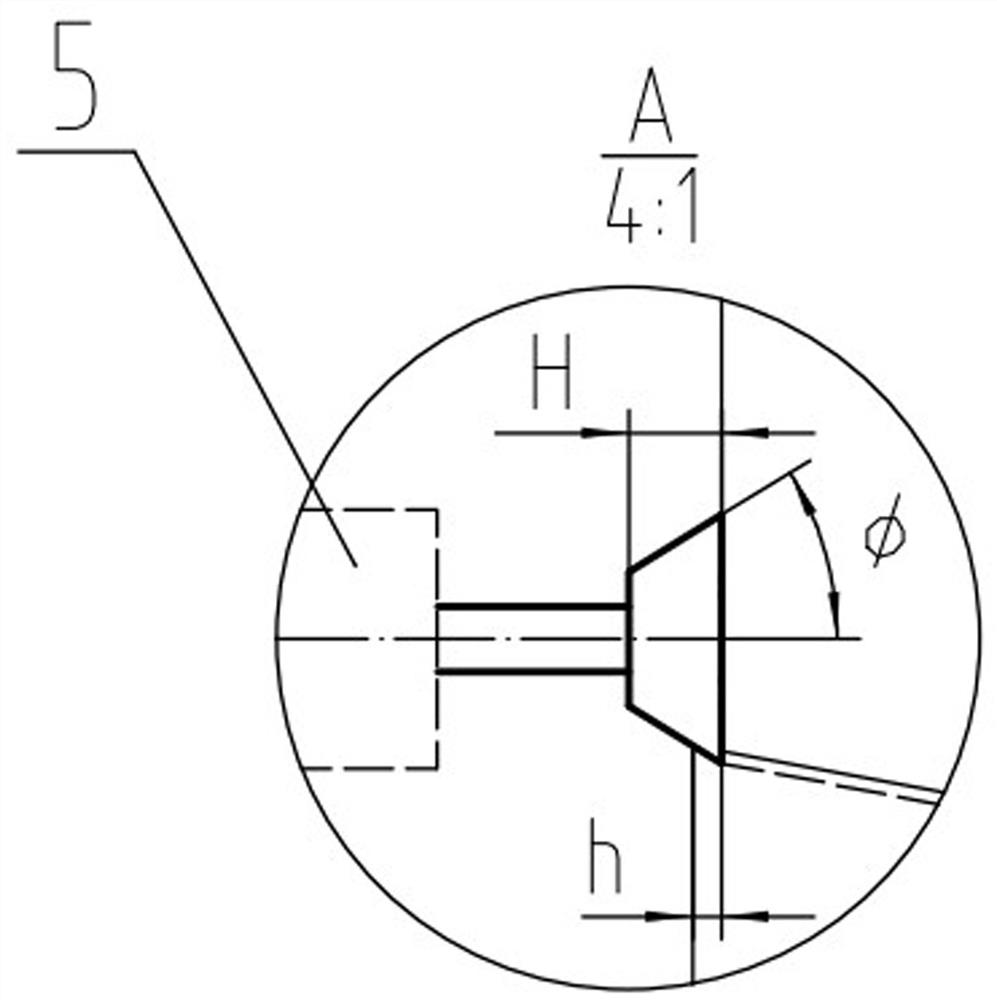

[0114] Take the parameters of the integral rubber tapping cutter 1 designed in the present invention and the parameters of the rubber tree 3 as examples to illustrate in detail, the angle Ω of the helix angle of the cutting surface of the rubber tree 3 is 60°, the tapping depth h is 2mm, and the radius of the rubber tree 3 is 60°. R is 150mm, the time T for one cycle of cutting is 1min, and the spindle speed n is 200rpm, then the tapping feed is determined by formula (7) as

[0115]

[0116] Then the feed per tooth is:

[0117]

[0118] The actual rubber tapping removal rate requires 0.189cm 3 / min, then from formula (9):

[0119]

[0120] Therefore, the half cone angle of the conical surface of the milling cutter head 101 is 5°.

[0121] When the actual tapping width h varies from 0 to 2mm, the corresponding milling area is:

[0122]

[0123] The cutting volume per tooth is:

[0124]

[0125] Calculate the tapping removal rate of the tapping milling cutter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com