Flip heat source chip and preparation method and application method thereof

A technology of chip and heat source, which is applied in the field of flip-chip heat source chip and its preparation, to achieve the effect of improving heat dissipation capacity, temperature uniformity and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

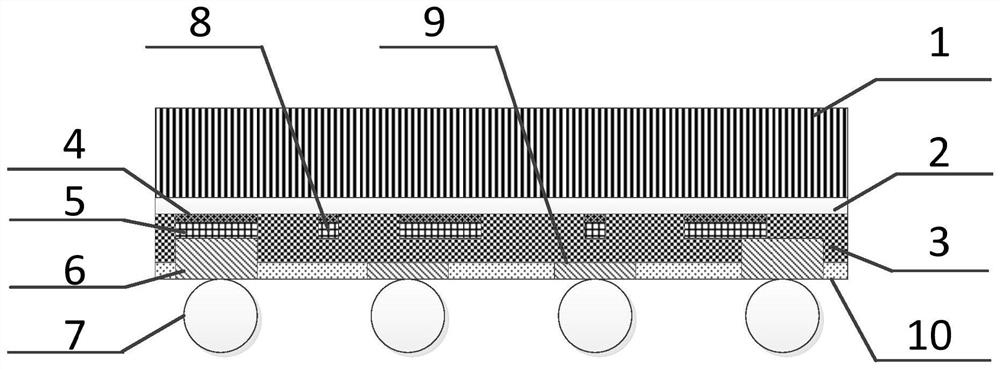

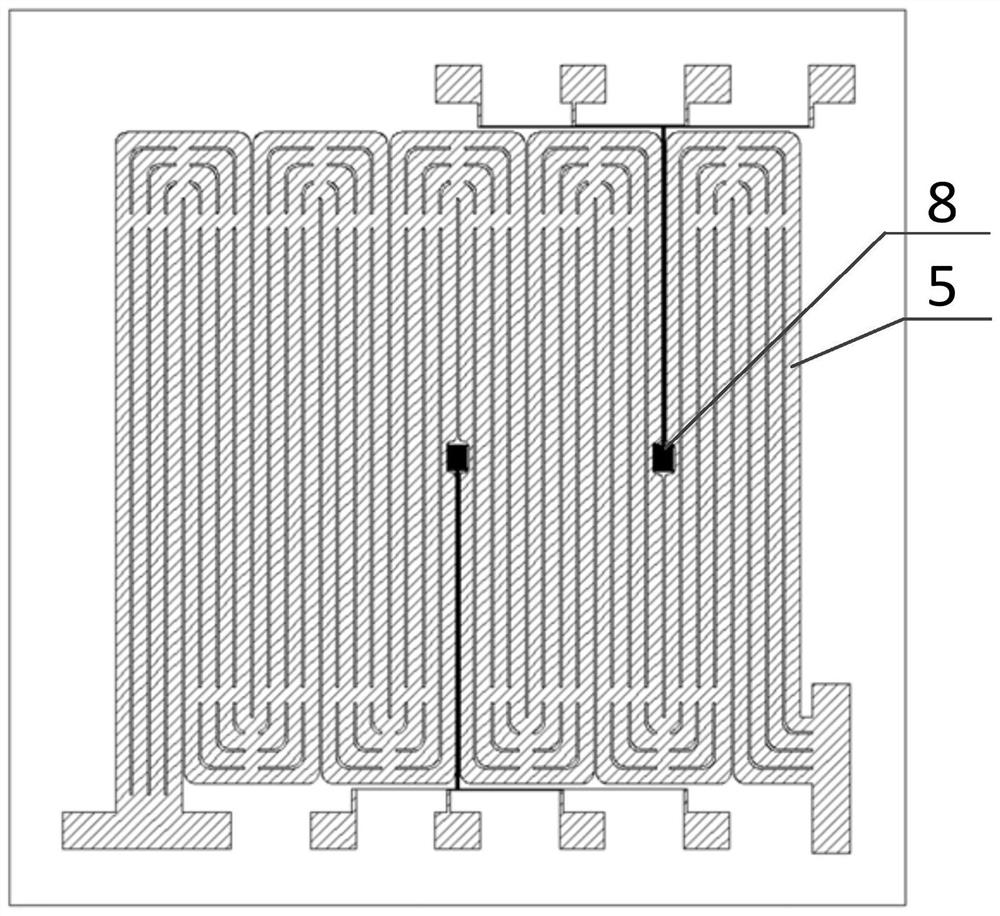

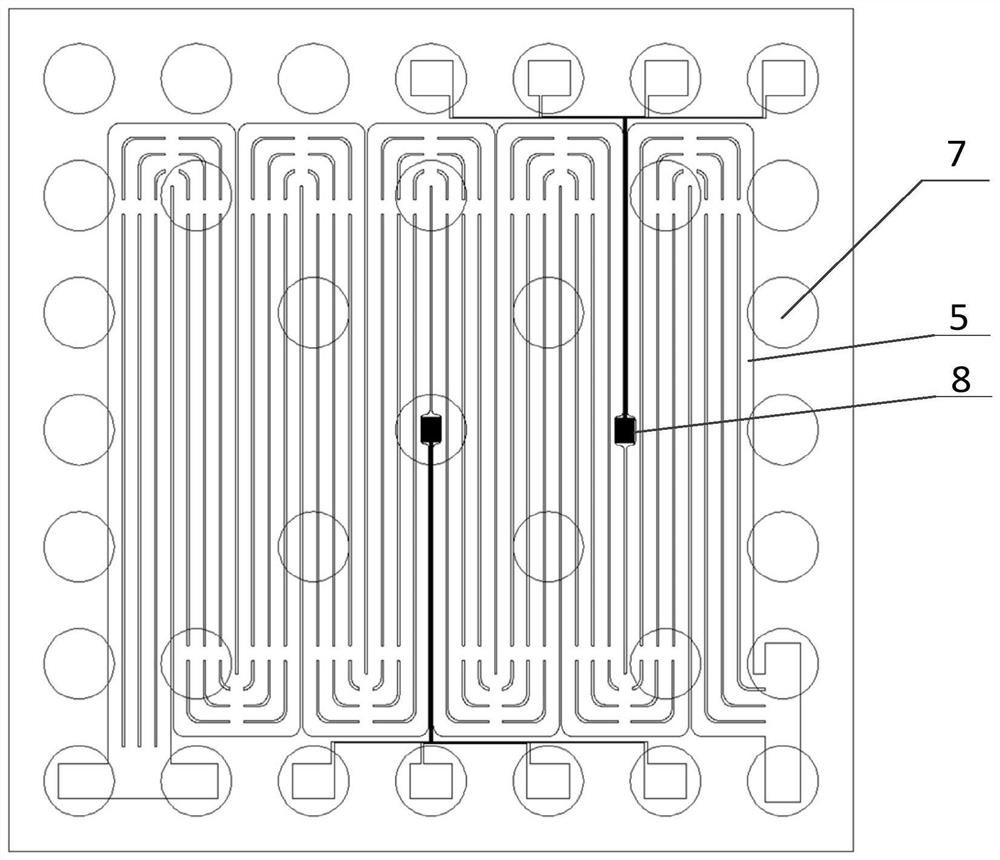

[0052] This embodiment provides a flip-chip heat source chip, such as figure 1 As shown, it includes: chip substrate 1, bottom insulating layer 2, heat conduction passivation layer 3, solder resist layer 10, adhesion layer 4, heating resistor 5, temperature sensor 8, metal interconnection pad 6, metal heat conduction pad 9 and micro-bumps 7, wherein the chip substrate 1, the bottom insulating layer 2, the heat conduction passivation layer 3 and the solder resist layer 10 are sequentially connected. A heating resistor 5 and a plurality of temperature sensors 8 are arranged in the thermally conductive passivation layer 3 , and the heating resistor 5 and the temperature sensors 8 are connected to the bottom insulating layer 2 through an adhesive layer 4 . A plurality of metal interconnection pads 6 and a plurality of metal heat conduction pads 9 are penetratingly arranged in the solder resist layer 10, the metal interconnection pads 6 are electrically connected to the heating res...

Embodiment 2

[0058] On the basis of Embodiment 1, this embodiment provides a flip-chip heat source chip, wherein: the chip substrate 1 is Si with a thickness of 300 μm; the bottom insulating layer 2 is SiO x Insulating film with a thickness of 300nm; the thermal conduction passivation layer 3 is SiN x Insulating film with a thickness of 400nm; the adhesion layer 4 is a Ti film with a thickness of 10nm; the heating resistor 5 and the temperature sensor 8 are W (tungsten) thin films with a thickness of 300nm, and the resistance of the heating resistor 5 is 20 ohms. The resistance of 8 is 2000 ohms; the metal interconnection pad 6 and the metal heat conduction pad 9 are Ti / Au metal pads; the solder resist layer 10 is SiN x The insulating film has a thickness of 100nm; the micro bumps 7 are gold bumps.

Embodiment 3

[0060] On the basis of Example 1, this embodiment provides a method for preparing a flip-chip heat source chip, such as Figure 6 shown, including the following steps:

[0061] Step 101: providing a chip substrate 1;

[0062] Step 102: growing a bottom insulating layer 2 on the surface of the chip substrate 1 using thin film vapor deposition technology;

[0063] Step 103: Prepare an adhesion layer 4 on the surface of the bottom insulating layer 2 by magnetron sputtering;

[0064] Step 104: Prepare a temperature-resistant thin film metal on the surface of the adhesion layer 4 by using thin film vapor deposition technology;

[0065] Step 105: using photolithography combined with thin film etching technology to prepare heat-resistant thin film metal into heating resistor 5 and temperature sensor 8;

[0066] Step 106: Prepare a thermally conductive passivation layer 3 on the surface of the heating resistor 5 and the temperature sensor 8 using thin film vapor deposition technolo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com