Fragrant and moist cigarette blasting bead and preparation method thereof

A technology for explosive beads and cigarettes, which is applied in the preparation of microspheres, tobacco, and applications, can solve the problems of affecting the sensory quality of cigarettes and the lack of comfort in the throat of cigarettes, so as to improve the taste characteristics of smoke, and achieve a clear and sweet aroma. Feature-enhancing, scent-styled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

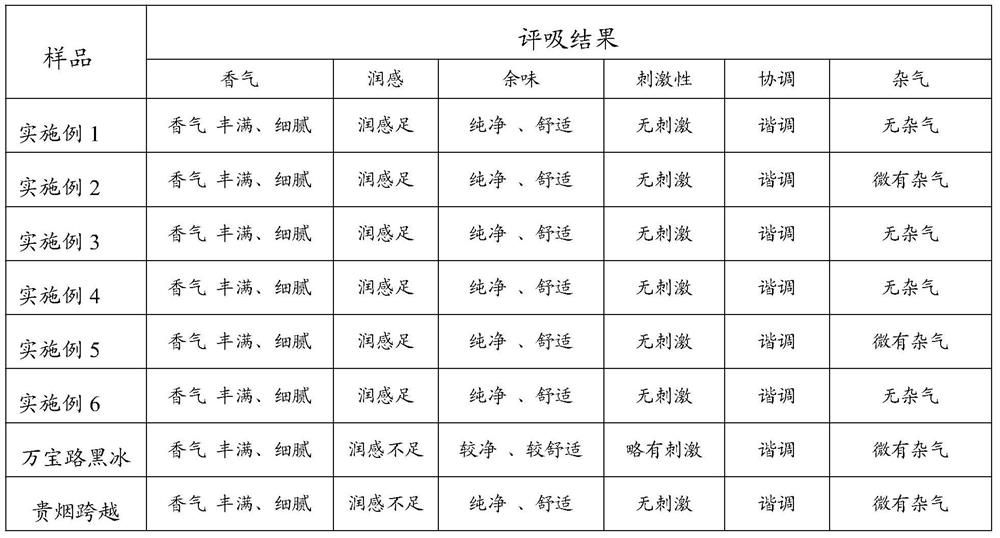

Examples

Embodiment 1

[0072] Embodiment 1: Preparation of popping beads for fragrant cigarettes of the present invention

[0073] The implementation steps of this embodiment are as follows:

[0074] A. Preparation of fragrant liquid core solution

[0075] Use a shearing machine to stir and mix pure water, blueberry essence and monoglyceride emulsifier according to the weight ratio of 10:0.1:0.1 to form a stable and uniform emulsion, and obtain a fragrant liquid core solution with blueberry flavor;

[0076] According to the method described in the specification of this application, the density of the fragrance liquid core solution is 0.9g / cm 3 .

[0077] B. Prepare the bead wall material solution

[0078] At normal temperature, 50 parts by weight of bio-based epoxy resin sold by Sicomin under the trade name bio-based epoxy resin resin, 38 parts by weight of polyester acrylic resin sold by Shanghai Fushun International Trade Co., Ltd. under the trade name polyester acrylic resin Resin and 3 parts...

Embodiment 2

[0085] Embodiment 2: Preparation of popping beads for fragrant cigarettes of the present invention

[0086] The implementation steps of this embodiment are as follows:

[0087] A. Preparation of fragrant liquid core solution

[0088] Use a shearing machine to stir and mix pure water, orange peel essence and sodium stearoyl lactylate emulsifier according to the weight ratio of 10:5:5 to form a stable and uniform emulsion, and obtain a fragrant liquid core solution with orange peel flavor;

[0089] According to the method described in the specification of this application, the density of the fragrance liquid core solution is 1.0g / cm 3 .

[0090] B. Preparation of Bead Wall Material Solution

[0091] At normal temperature, 60 parts by weight of bio-based epoxy resin sold by Sicomin under the trade name bio-based epoxy resin, 42 parts by weight of polyester acrylic resin sold by Shanghai Fushun International Trade Co., Ltd. under the trade name polyester acrylic resin The resin ...

Embodiment 3

[0098] Embodiment 3: Preparation of popping beads for fragrant cigarettes of the present invention

[0099] The implementation steps of this embodiment are as follows:

[0100] A. Preparation of fragrant liquid core solution

[0101] Use a shearing machine to mix pure water, cantaloupe flavor and calcium stearoyl lactylate emulsifier at a weight ratio of 10:1:1 to form a stable and uniform emulsion, and obtain a cantaloupe-flavored liquid core solution;

[0102] According to the method described in the specification of this application, the density of the fragrance liquid core solution is 1.2g / cm 3 .

[0103] B. Preparation of Bead Wall Material Solution

[0104] At normal temperature, 20 parts by weight of bio-based epoxy resin sold by Sicomin under the trade name bio-based epoxy resin, 46 parts by weight of polyurethane acrylate sold under the trade name polyurethane acrylate by Chengdu Sicheng Optoelectronics Co., Ltd. and 1 The OmnipolBP photosensitizer sold under the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com