Water-based capsule and preparation method thereof

A capsule, water-based technology, applied in food science, application, tobacco, etc., can solve the problem of no water or water-soluble core liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Example 1: Preparation of aqueous capsules

[0069] The preparation steps of the preparation method are as follows:

[0070] A. Preparation of water-soluble core liquid

[0071] According to the weight ratio of pure water and ethyl acetate water-soluble flavor and fragrance water-soluble substance of 1:0.01, the water-soluble substance is dissolved in pure water under stirring to obtain a density of 0.9g / cm 3 The water-soluble core liquid;

[0072] B. Preparation of capsule wall material solution

[0073] Stir 50 parts by weight of bisphenol A epoxy resin, 38 parts by weight of urethane acrylate other resins, and 3 parts by weight of 5-aminolevulinic acid photosensitizer at room temperature, stir and mix thoroughly, then keep it in the dark for 12.0h, remove Air bubbles, get a density of 1.0g / cm 3 The capsule wall material solution;

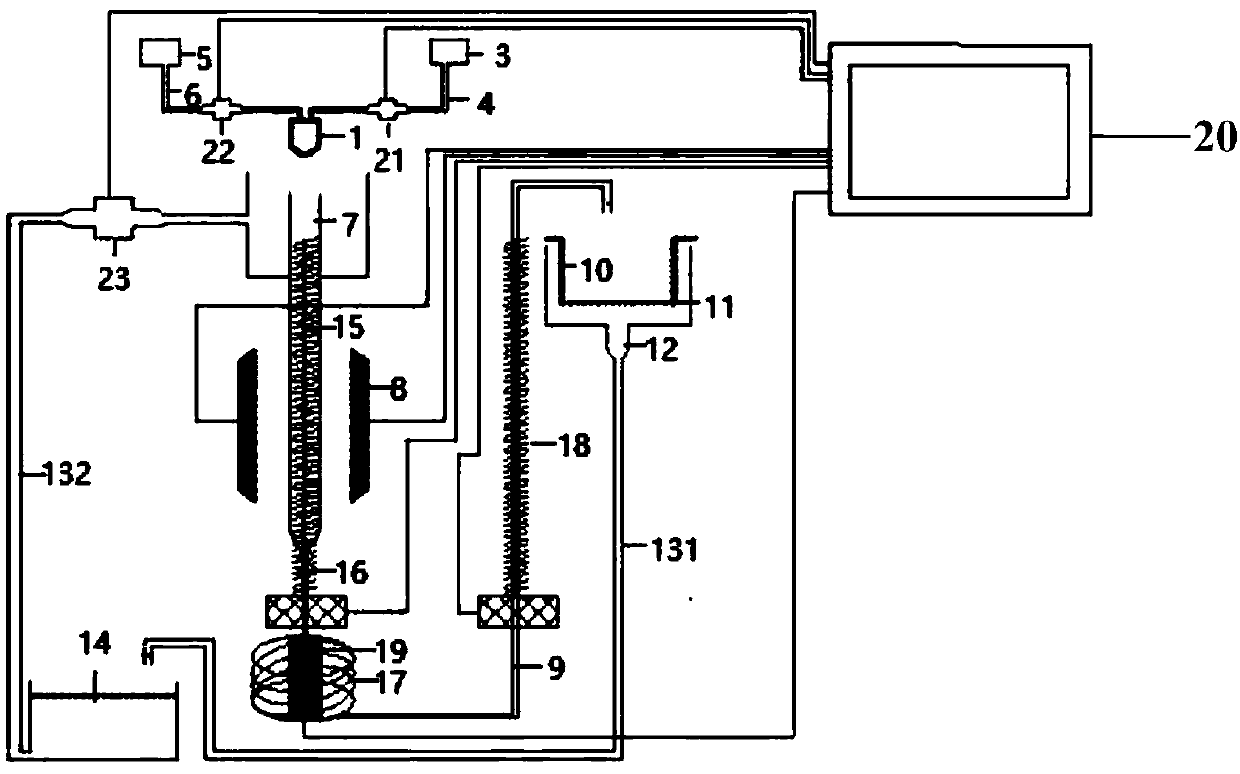

[0074] C. Water-based capsule drip system

[0075] According to 8 parts by weight of the capsule wall material liquid and 92 parts by weight of the ...

Embodiment 2

[0079] Example 2: Preparation of aqueous capsules

[0080] The preparation steps of the preparation method are as follows:

[0081] A. Preparation of water-soluble core liquid

[0082] According to the weight ratio of pure water to the water-soluble substance of the protein plant extract of 1:0.08, the water-soluble substance is dissolved in the pure water under stirring to obtain a density of 1.0g / cm 3 The water-soluble core liquid;

[0083] B. Preparation of capsule wall material solution

[0084] Stir 60 parts by weight of bisphenol A epoxy resin, 42 parts by weight of polyester acrylic resin and other resins, and 4 parts by weight of meta-tetrahydroxyphenyl chlorin photosensitizer at room temperature, stir and mix thoroughly, and then stand in the dark Store for 12.4h, remove bubbles, and get a density of 1.2g / cm 3 The capsule wall material solution;

[0085] C. Water-based capsule drip system

[0086] The dropping pill device described in Example 1 was used for dropping. According ...

Embodiment 3

[0088] Example 3: Preparation of aqueous capsules

[0089] The preparation steps of the preparation method are as follows:

[0090] A. Preparation of water-soluble core liquid

[0091] According to the weight ratio of pure water to the water-soluble substance of plum extract 1:0.1, the water-soluble substance is dissolved in pure water under stirring to obtain a density of 1.1g / cm 3 The water-soluble core liquid;

[0092] B. Preparation of capsule wall material solution

[0093] Mix 20 parts by weight of bisphenol A epoxy resin, 46 parts by weight of polyether acrylic resin and other resins with 1 part by weight of protoporphyrin tin photosensitizer at room temperature, stir and mix thoroughly, and then store for 12.6 hours in the dark to remove air bubbles , The density is 1.2g / cm 3 The capsule wall material solution;

[0094] C. Water-based capsule drip system

[0095] The dropping pill device described in Example 1 was used for dropping. According to 1 part by weight of the capsule w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com