Anti-leakage water blasting ball and preparation method thereof

An anti-leakage and explosion-proof technology, applied in the fields of food science, application, coating, etc., can solve the problem of no water or water-soluble material core liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

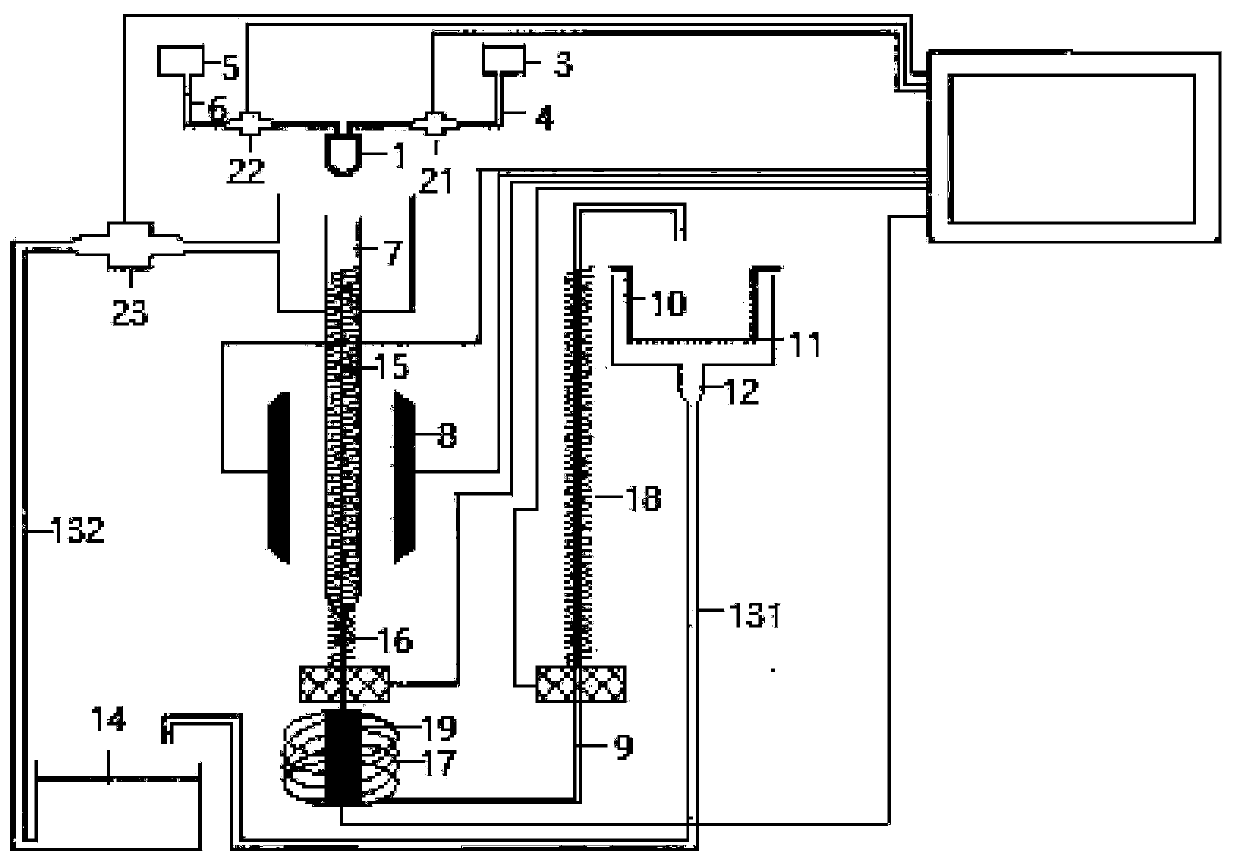

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1: Preparation of anti-seepage water blasting beads

[0084] The preparation steps of this preparation method are as follows:

[0085] A. Preparation of water-soluble core fluid

[0086] According to the weight ratio of pure water to plum extract 1:1, dissolve the plum extract in pure water under stirring to obtain a density of 0.9g / cm 3 Water-soluble substance core fluid;

[0087] B. Preparation of the material liquid for the first photosensitive resin rubber layer

[0088] Stir 20 parts by weight of bisphenol A epoxy resin, 50 parts by weight of polyurethane acrylate and 1 part by weight of KIP150 photosensitizer at room temperature and mix thoroughly, then keep it in the dark for 12.0 hours, remove air bubbles, and obtain a density of 0.9g / cm 3 The first photosensitive resin rubber layer material liquid;

[0089] C, the preparation of the second polyacrylic resin rubber layer material liquid

[0090] Put the polyacrylic acid resin in an ethanol solu...

Embodiment 2

[0096] Embodiment 2: Preparation of anti-seepage water blasting beads

[0097] The preparation steps of this preparation method are as follows:

[0098] A. Preparation of water-soluble core fluid

[0099] According to the weight ratio of pure water to ethyl acetate 1:0.5, dissolve ethyl acetate in pure water under stirring to obtain a density of 1.0g / cm 3 Water-soluble substance core fluid;

[0100] B. Preparation of the material liquid for the first photosensitive resin rubber layer

[0101] 70 parts by weight of bisphenol A type epoxy resin, 30 parts by weight of polyester acrylic resin and 5 parts by weight of Omnipol BP photosensitizer were stirred and fully mixed at room temperature, then kept in the dark for 12.2 hours, and air bubbles were removed to obtain a density of 1.0g / cm 3 The first photosensitive resin rubber layer material liquid;

[0102] C, the preparation of the second polyacrylic resin rubber layer material liquid

[0103] Put the polyacrylic acid res...

Embodiment 3

[0109] Embodiment 3: Preparation of anti-seepage water blasting beads

[0110] The preparation steps of this preparation method are as follows:

[0111] A. Preparation of water-soluble core fluid

[0112] According to the weight ratio of pure water to glutamic acid 1:0.4, dissolve the amino acid in pure water under stirring to obtain a density of 1.2g / cm 3 Water-soluble substance core fluid;

[0113] B. Preparation of the material liquid for the first photosensitive resin rubber layer

[0114] Mix 50 parts by weight of bisphenol A type epoxy resin, 40 parts by weight of polyether acrylic resin and 3 parts by weight of Irgacure 127 at room temperature, stir and mix well, then keep it in the dark for 12.3 hours, remove air bubbles, and obtain a density of 1.2g / cm 3 The first photosensitive resin rubber layer material liquid;

[0115] C, the preparation of the second polyacrylic resin rubber layer material liquid

[0116] Put the polyacrylic acid resin in an ethanol soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com