Numerical control drilling machine for punching surface of mechanical part

A technology of mechanical parts and CNC drilling machines, which is applied in the direction of metal processing mechanical parts, drilling/drilling equipment, boring machines/drilling machine parts, etc. to improve safety and insulation, avoid wire slipping and breakage, and reduce potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

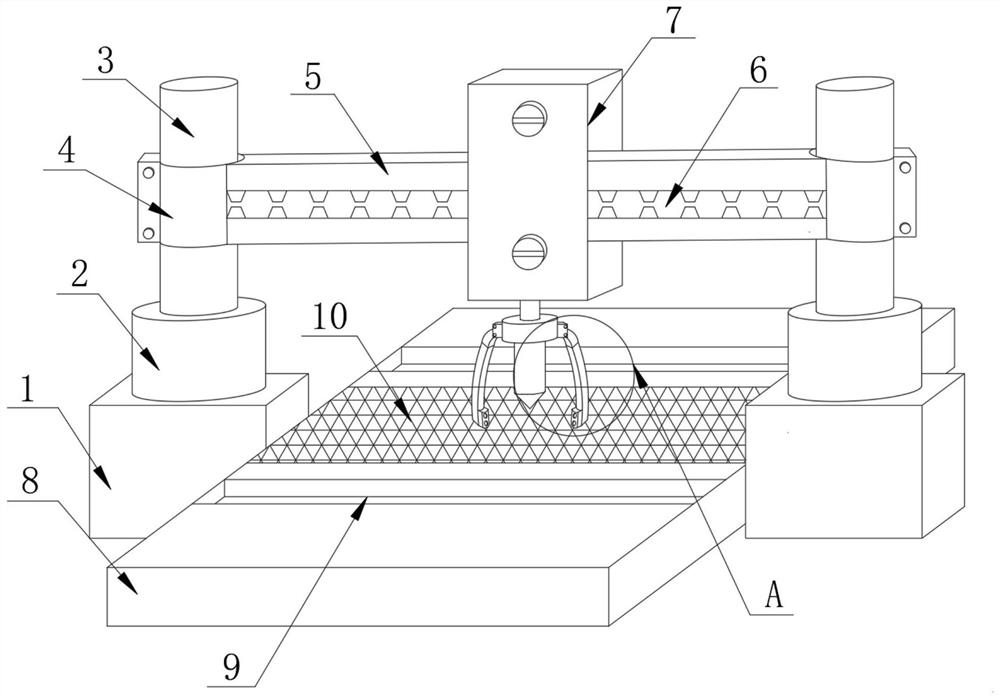

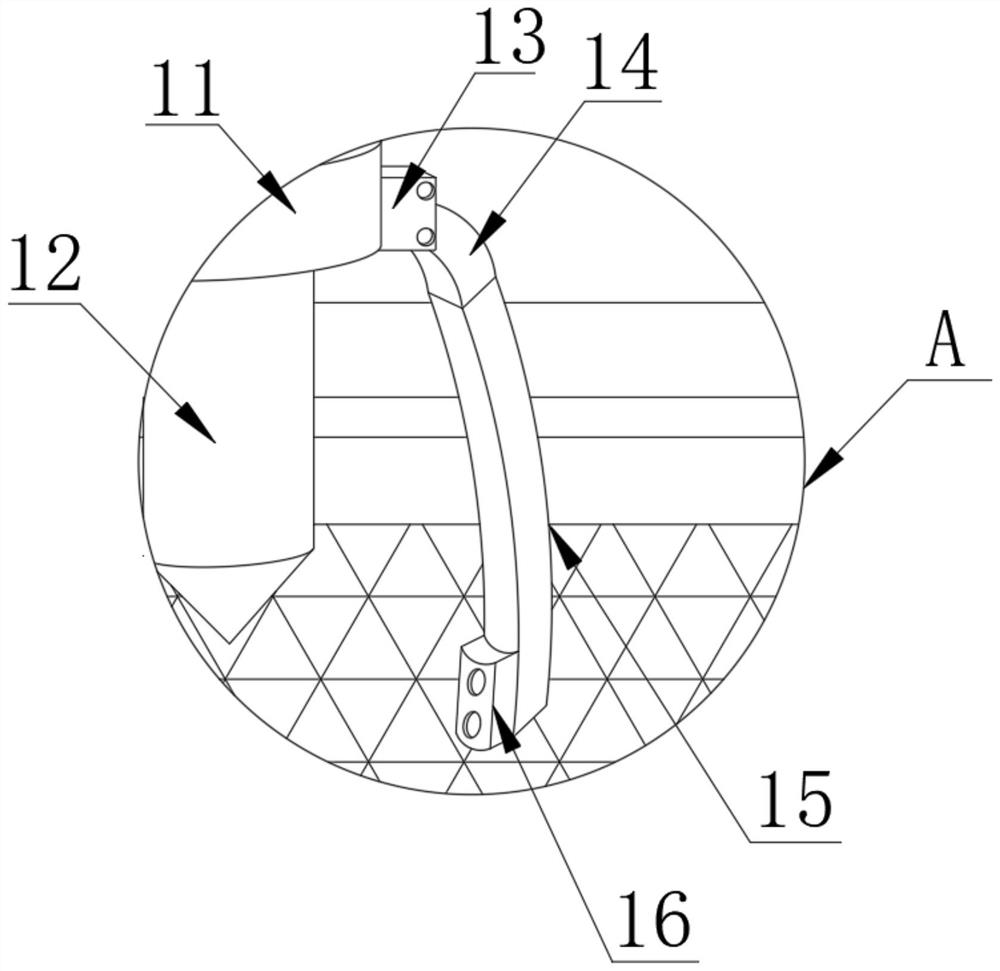

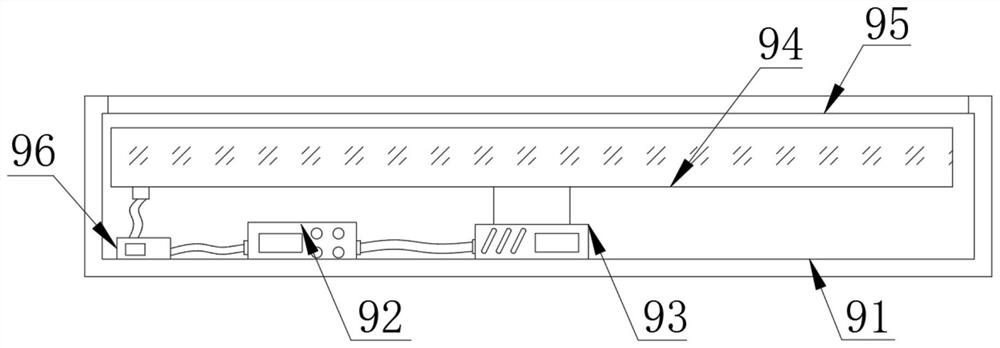

[0031] as attached figure 1 with attached Figure 8 A numerically controlled drilling machine for punching holes on the surface of mechanical parts is shown, comprising a drilling machine base 1, the top of the drilling machine base 1 is fixedly fitted with a fastening adapter frame 2, and the top of the fastening adapter frame 2 is fixedly sleeved with a connection The support column 3, the middle part of the outer surface of the connected support column 3 is fixedly fitted with a mounting bracket 4, and one side of the mounting bracket 4 is fixedly equipped with a drill slide frame 5, and the middle part of the drill slide frame 5 is fixed. A sliding internal rack 6 is set, the middle part of the outer surface of the sliding internal rack 6 is movable with a sliding connection box 7, and a processing table 8 is fixedly installed on one side of the drilling machine base 1, and the outer surface of the processing table 8 The movable cover is provided with a protective assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com