Design method of honing wheel for powerful gear honing

A technology of honing and gears, which is applied to components with teeth, belts/chains/gears, gear teeth, etc., which can solve the problem of long dressing time of honing wheels, inability to accurately determine the structure of honing wheels, and the size of honing wheel blanks , the target gear structure cannot be verified, etc., to achieve the effect of increasing service life, reducing dressing time, and simplifying the calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

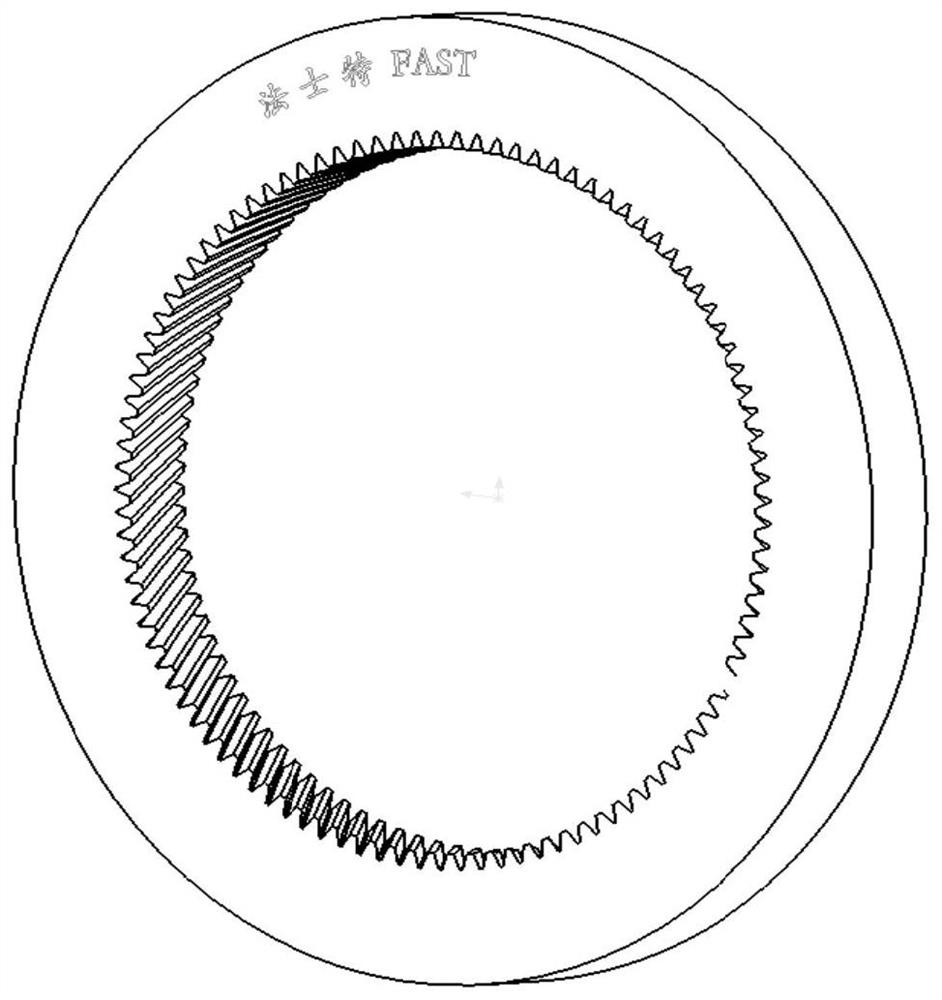

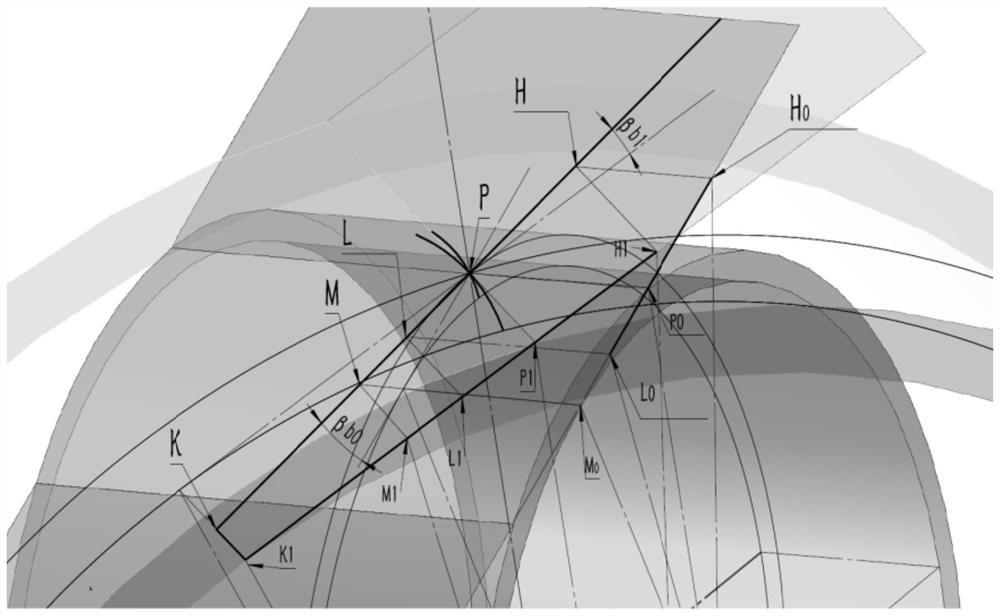

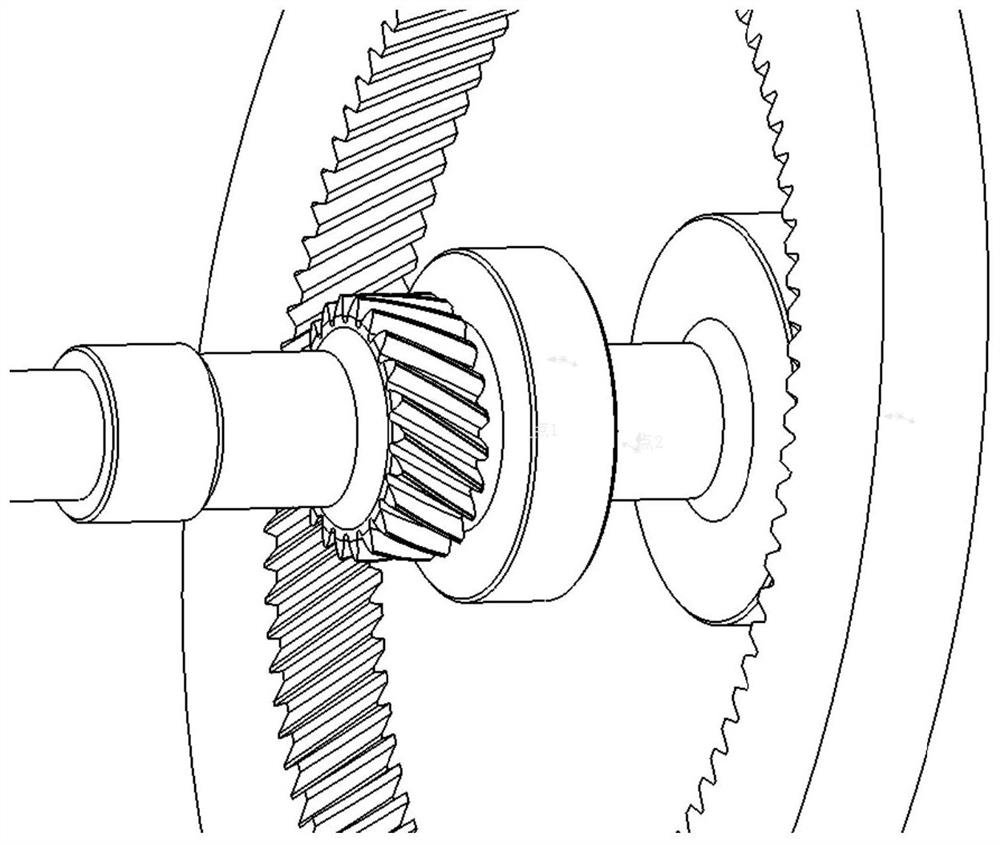

[0082] Power honing is an advanced precision machining technology for hard tooth surfaces. Compared with traditional worm gear grinding, power honing has obvious advantages in tooth surface texture and residual stress after grinding. At the same time, it has high honing accuracy and surface roughness. Good, and can grind gear parts with structural limitations. Power honing grinding wheel (referred to as honing wheel) is the main tool used in the application of power honing technology. Based on the cutting principle of honing wheel grinding gear, the present invention proposes a design method of honing wheel, which can be used to design the honing wheel of gears with different tooth parameters using powerful honing technology, not only can be applied to the early stage design o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com