Double-wire MIG welding additive manufacturing system and method based on particle swarm optimization

A particle swarm optimization and additive manufacturing technology, applied in manufacturing tools, welding equipment, welding accessories, etc., can solve problems such as hump weld bead and undercut, achieve small overshoot, short dynamic response time, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

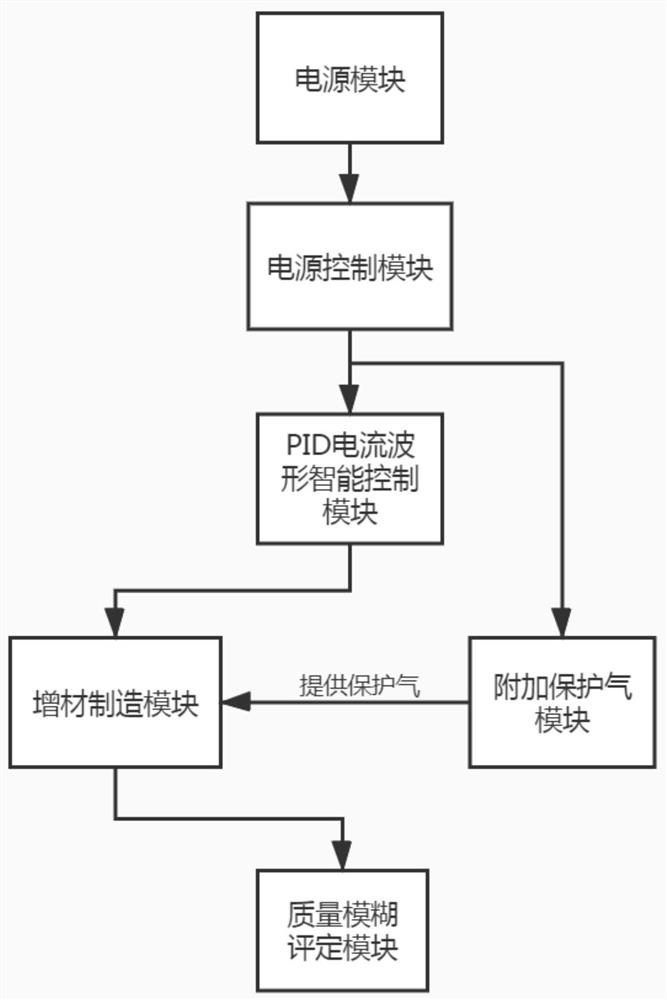

[0050] Such as figure 1 As shown, the present invention, a kind of twin-wire MIG welding additive manufacturing system based on particle swarm optimization, comprises:

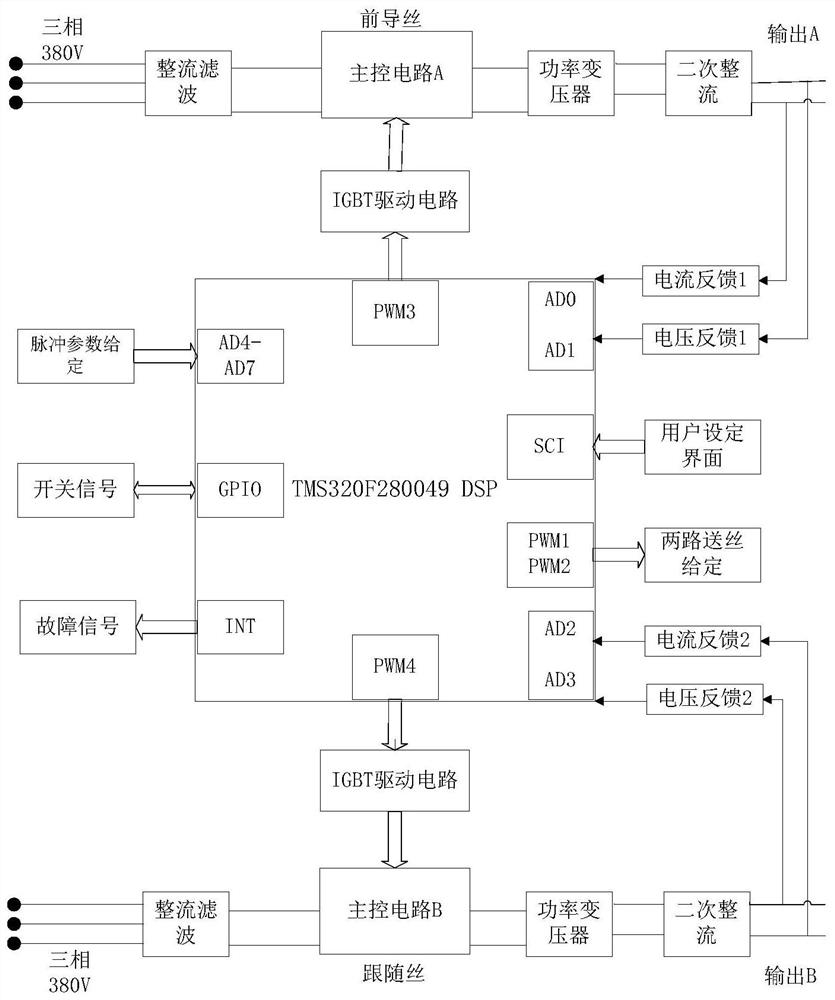

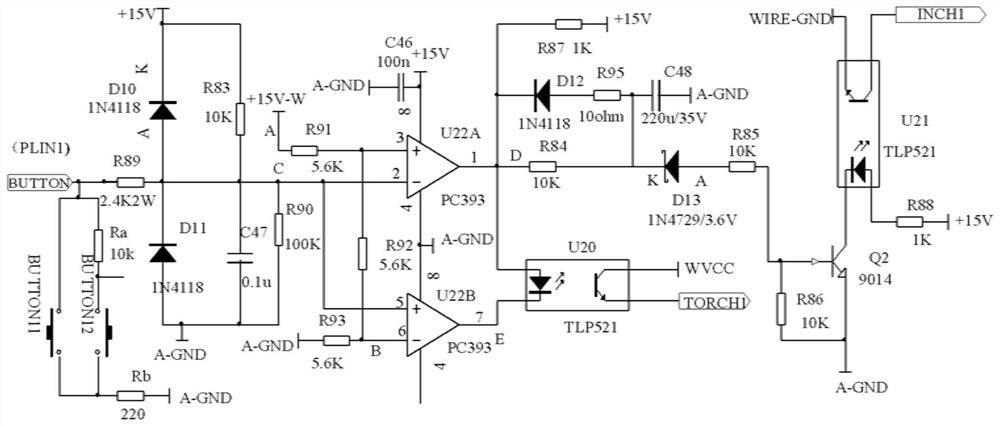

[0051] A power supply module, a power supply control module, an additive manufacturing module, a fuzzy quality evaluation module, a PID current waveform intelligent control module and an additional shielding gas module; the power supply module includes a DSP control core, a main control circuit, a power circuit and a user setting interface; The power control module includes a main program module, a function module, a parameter setting module and an initialization module; the additive manufacturing module includes a welding torch, an additive manufacturing robot and a control system, and is used for twin-wire MIG welding additive manufacturing;

[0052] The quality fuzzy evaluation module is used for fuzzy evaluation of the quality of the double-wire MIG welding additive manufacturing sample;

[0053] The PID ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com