Telescopic conveyor belt device

A conveyor belt and retractable technology, applied in the field of conveyor belts, can solve the problems of inability to adjust and low applicability, and achieve the effects of occupying a small space, prolonging life, and ensuring transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

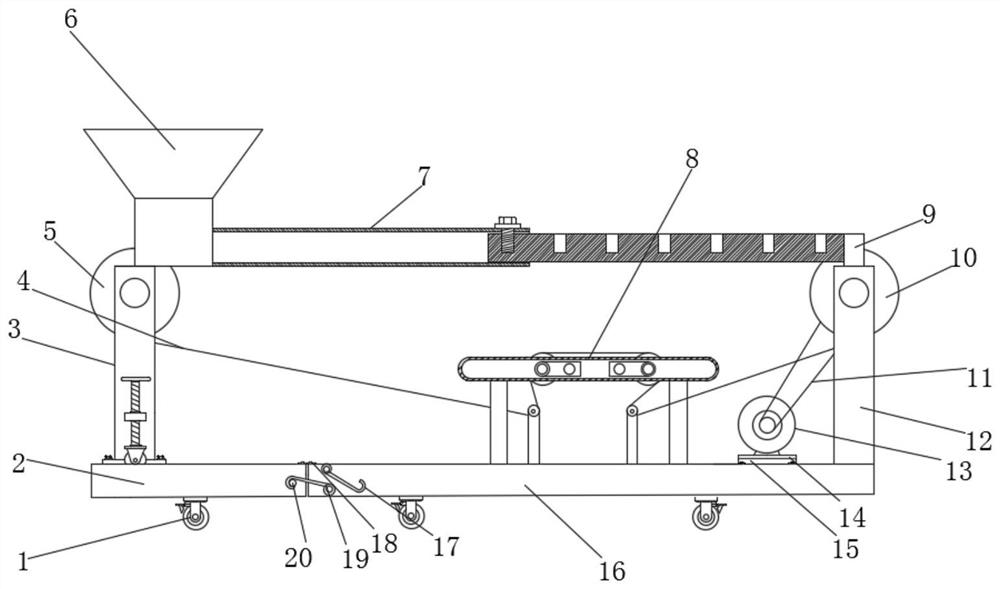

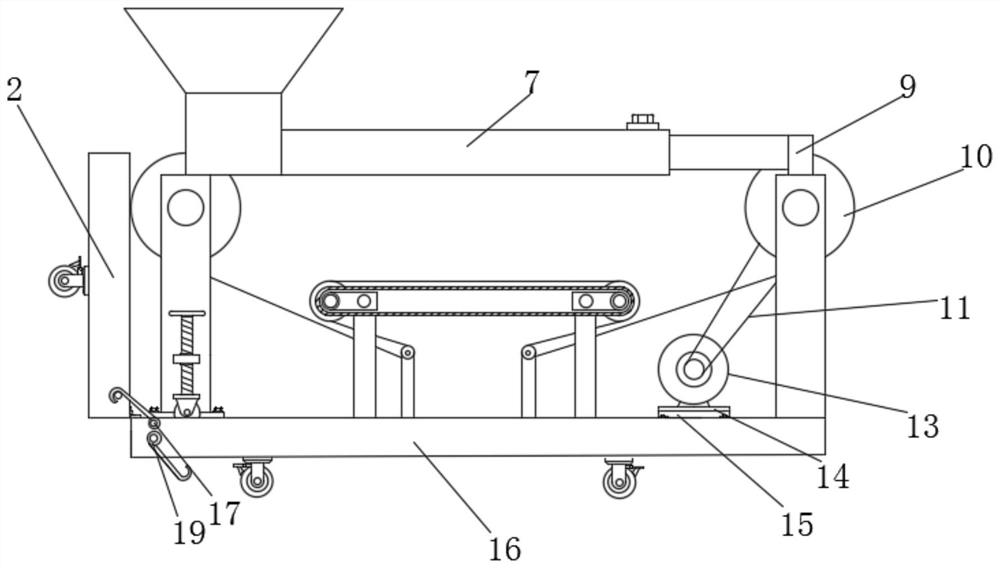

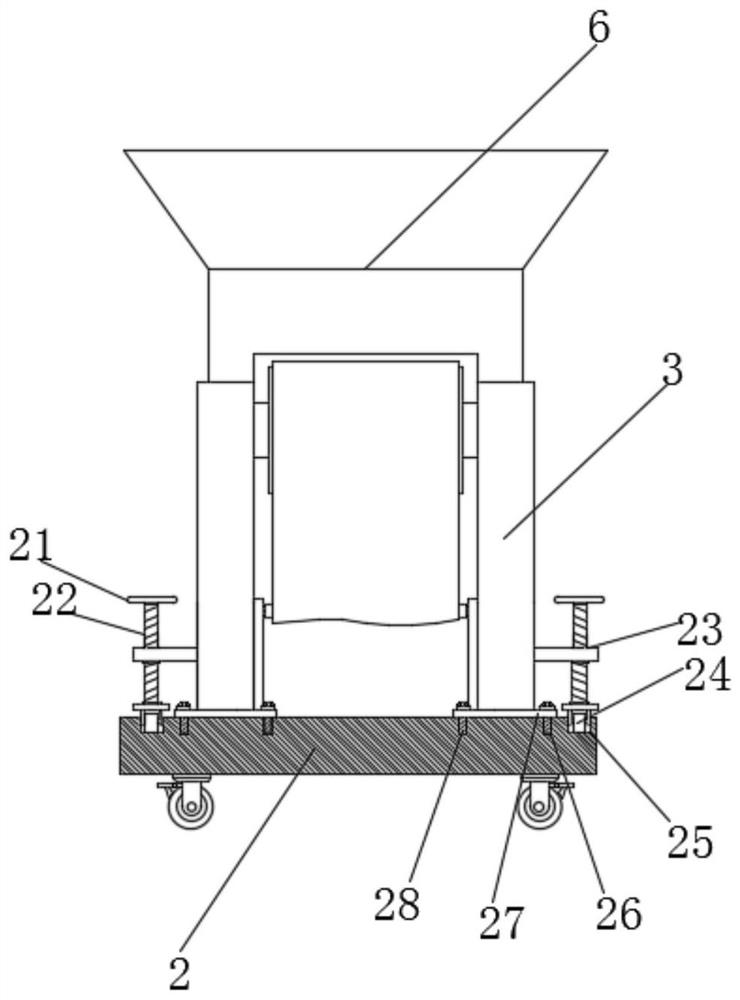

[0034] A telescopic conveyor belt device, comprising a fixed seat 16, a second support frame 12 is arranged on the right side of the upper end of the fixed seat 16, a driving wheel 10 is mounted on the upper end of the second supporting frame 12, and a motor 13 is arranged on the lower left side of the driving wheel 10 , the output end of the motor 13 is provided with a belt 11, the other end of the belt 11 is arranged on the rotating shaft of the driving wheel 10, the lower end of the motor 13 is provided with a fixed base 14, and the left side of the fixed base 16 is provided with a movable plate 2, the movable plate 2 and the fixed seat 16 are hinged through the hinge 18, the upper end of the movable plate 2 is provided with a first support frame 3, and the upper end of the first support frame 3 is provided with a driven wheel 5, and the outside of the driven wheel 5 and the driving wheel 10 is wrapped with a conveyor belt 4, The lower end of the first support frame 3 is pro...

Embodiment 2

[0043] Optionally, see figure 1 , 7-10, a telescopic conveyor belt device, the lower end surface of the fixed base 14 is provided with a tensioning assembly 15;

[0044] The tensioning assembly 15 includes a support seat 156 fixed on the upper end of the fixed seat 16. A sliding groove 152 is arranged horizontally in the middle of the supporting seat 156. The end of the sliding groove 152 away from the driving wheel 10 is open, and the inside of the sliding groove 152 is provided with a sliding block. 151, the right side of the sliding block 151 is provided with a spring 157, one end of the spring 157 is connected to the sliding block 151, and the other end is connected to the closed end of the sliding groove 152, the upper end of the sliding block 151 is provided with a third fixing bolt 154, the third The fixing bolt 154 penetrates into the fixed base 14 , the bottom, front and rear sides of the support base 156 are provided with a fixing plate 153 , the inside of the fixing...

Embodiment 3

[0048] Optionally, see figure 1 , 2 , 7, a telescopic conveyor belt device, the upper end of the first support frame 3 is provided with a feed hopper 6, the feed hopper 6 is located above the conveyor belt 4, the right end of the feed hopper 6 is provided with a baffle mechanism 7, the baffle mechanism 7 is arranged on both sides of the conveyor belt 4, the other end of the baffle mechanism 7 is connected with a fixed block 9, and the fixed block 9 is fixed on the upper end of the second support frame 12;

[0049] The baffle plate mechanism 7 includes a sleeve 71 fixed on the right end of the feed hopper 6, the inside of the sleeve 71 is provided with a retaining rod 73, and the retaining rod 73 is provided with a plurality of first fixing screw holes 74, and the sleeve 71 is adjacent to the retaining rod A first fixing bolt 72 corresponding to the first fixing screw hole 74 is provided on one side upper end of 73 .

[0050] Specifically, in order to facilitate unloading, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com