Hot-galvanizing machining device

A processing device, hot-dip galvanizing technology, applied in hot-dip galvanizing process, metal material coating process, cleaning method using tools, etc., can solve the problems of reducing the efficiency of impurity cleaning, time-consuming and labor-intensive, etc., to improve cleaning efficiency and reduce wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

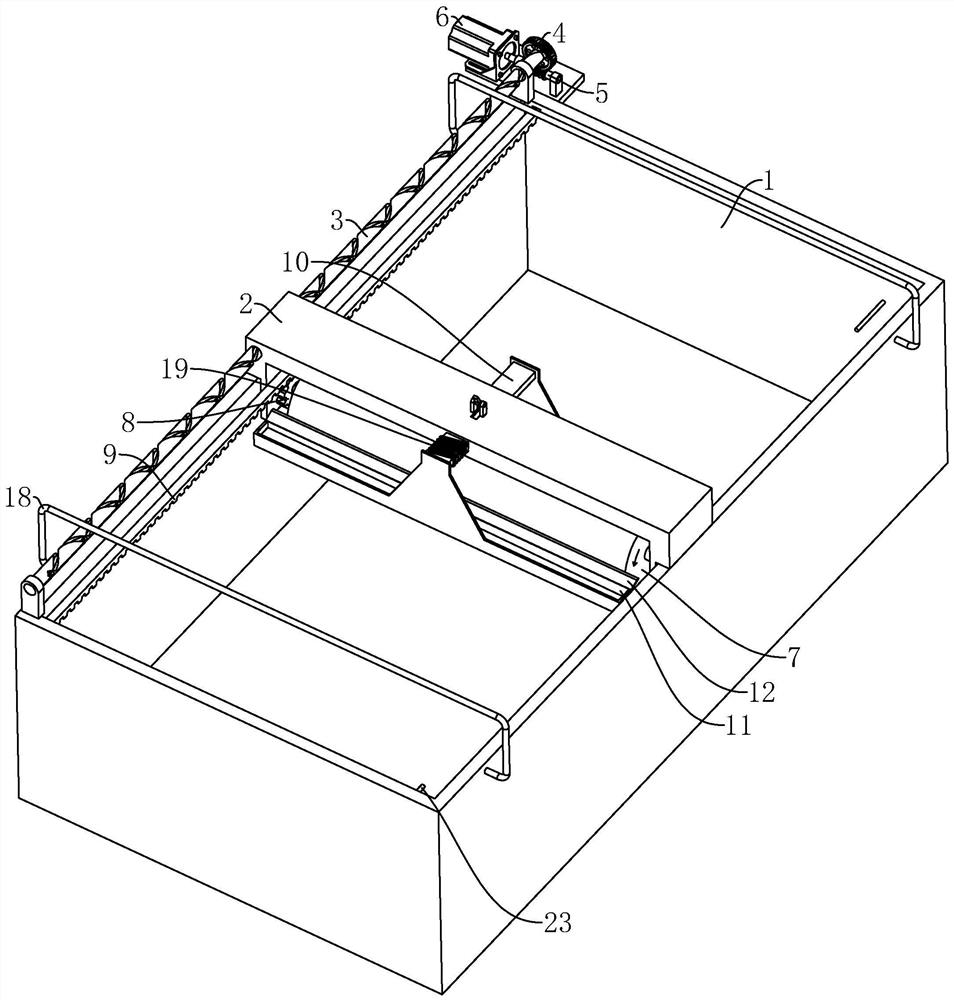

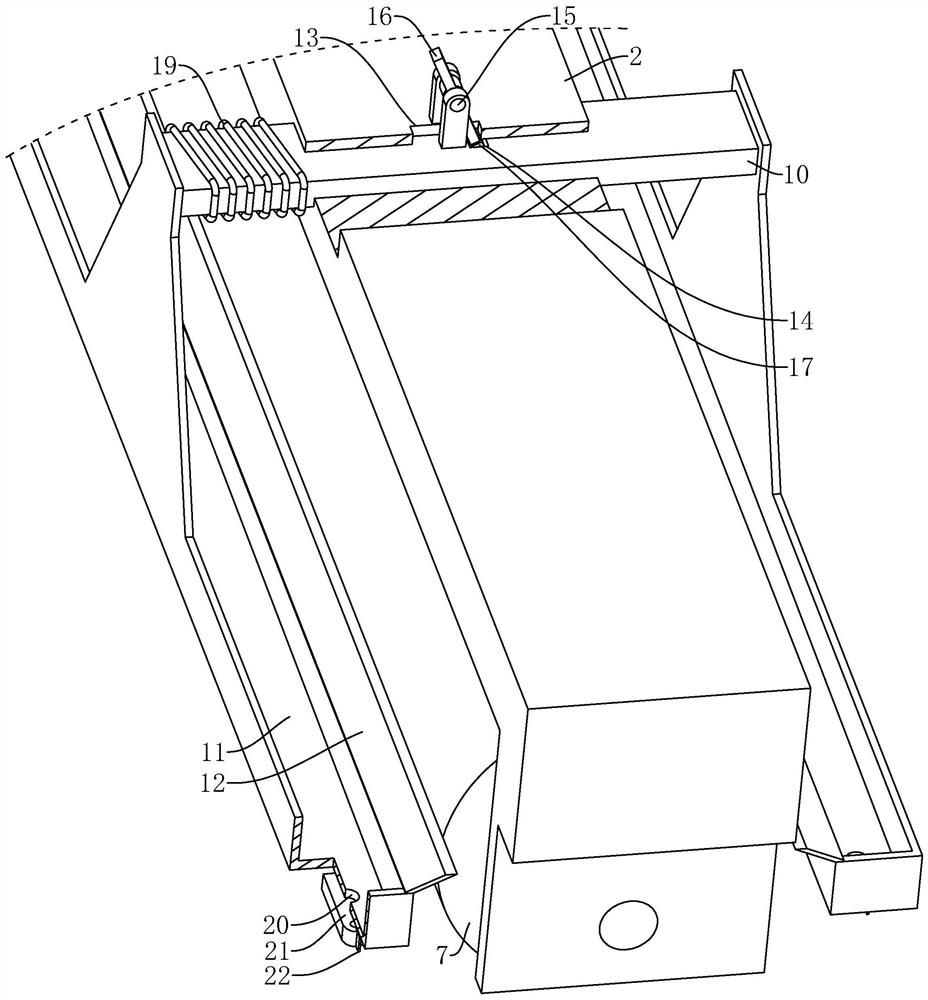

[0029] Contraction below Figure 1-2 Further detailed description of the present application.

[0030] Refer figure 1 A hot-dip galvanized processing apparatus comprising a galvanized tank containing zinc solution 1, sliding on the galvanizing tank 1 having the same slider 2 as the galvanized cell 1 width direction, the sliding direction and plating of the slider 2 The length direction of the zinc pool 1 is the same. The galvanized tank 1 is rotated and connected to the same reciprocating wire rod 3 as the galvanized cell 1 length direction, and the retro rod 3 passes through the slider 2 and the slider 2 is threaded, and one end side wall of the retriever rod 3 is fixed. A worm wheel 4 is provided, and the galvanized tank 1 is rotated and connected to a worm 5 that is engaged with the worm wheel 4. The galvanizing pool 1 is also attached to the motor 6 for rotating the worm 5, and the motor 6 is connected to the power supply. The slider 2 is rotated and connected to the attachment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com