Anti-falling building outer wall coating

An anti-shedding technology for building exterior walls, applied in coatings, buildings, building structures, etc., can solve problems such as local strength weakening, shedding, and local stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

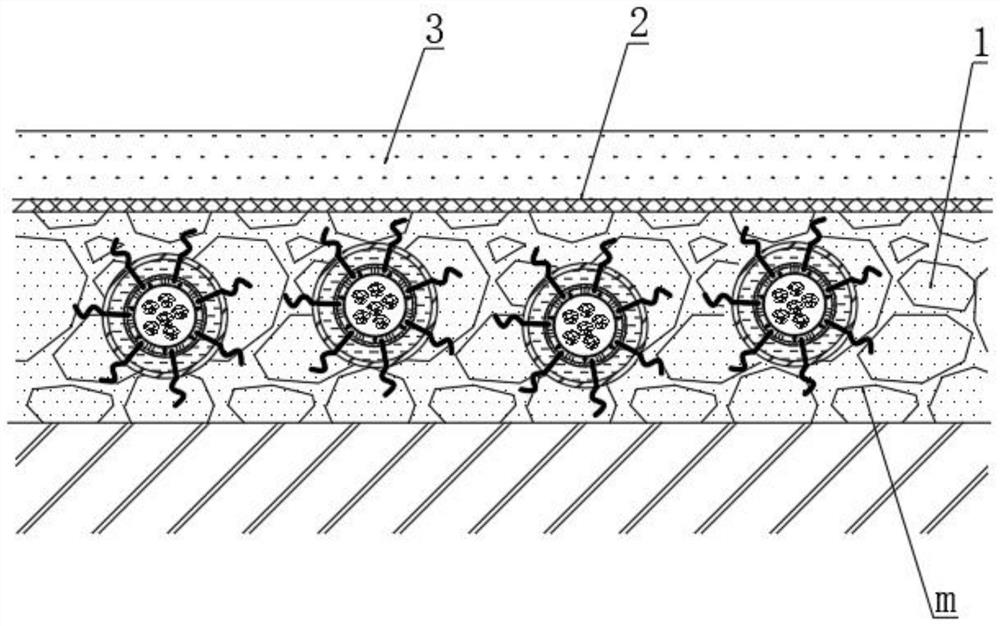

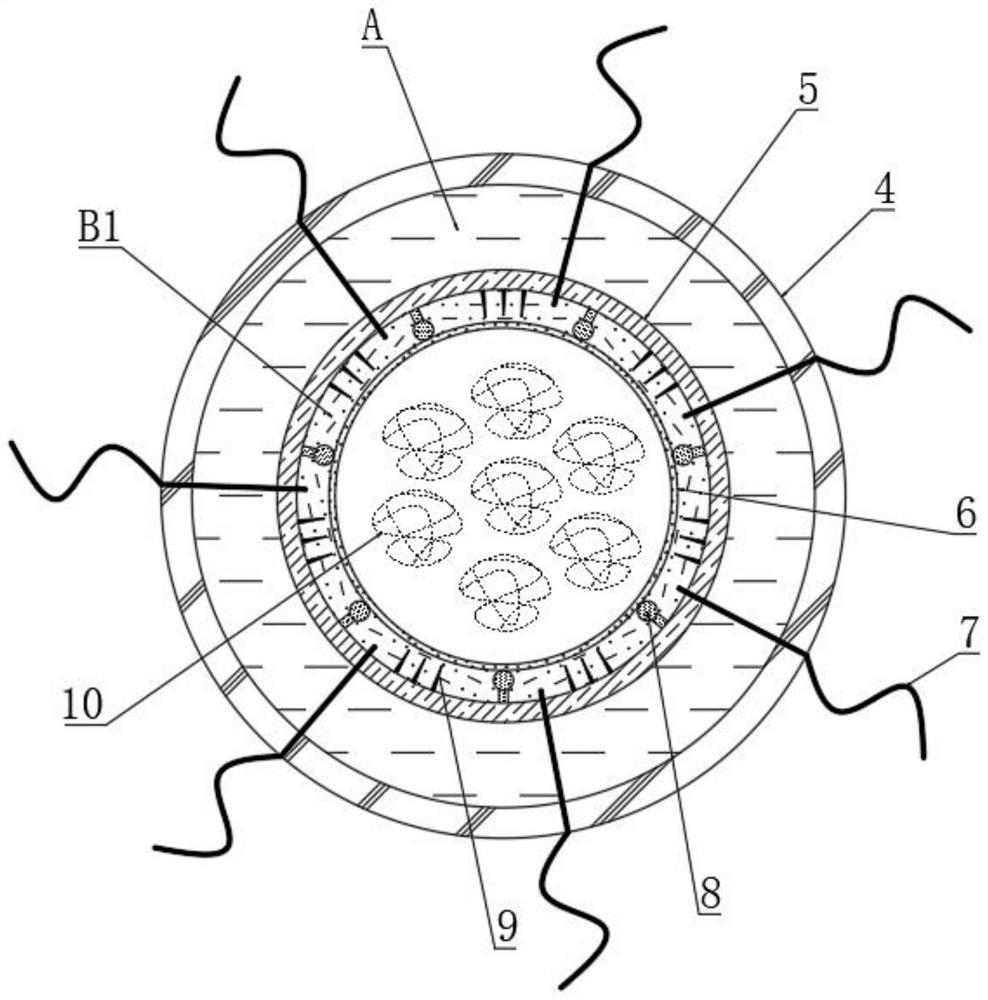

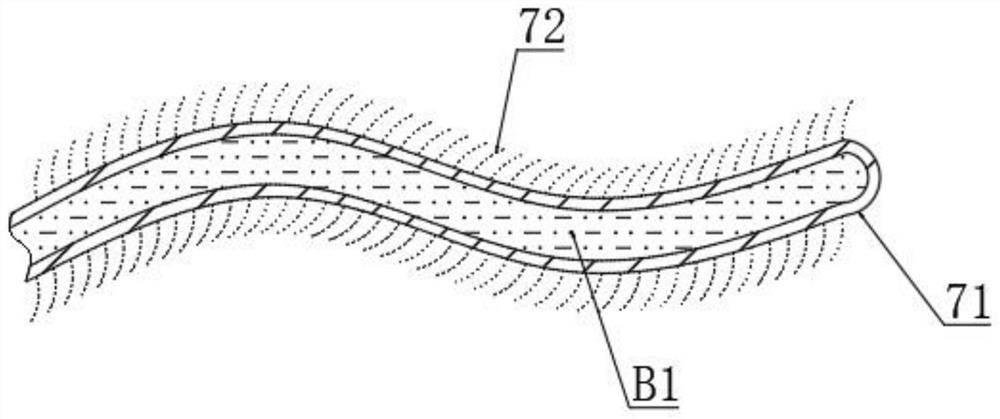

[0045] see figure 1 , a building exterior wall coating with anti-falling off, comprising a fracture buffer layer 1 coated on the surface of the exterior wall, the outer surface of the fracture buffer layer 1 is fixedly connected with a grid cloth 2, the fracture buffer layer 1 and a grid The surface layer 3 is fixedly connected between the cloth 2, and the inside of the crack buffer layer 1 is evenly filled with a plurality of tearing and replenishing particles. The coating preparation method is as follows:

[0046] S1. Prepare the exterior wall paint, and freeze the tearing and replenishing particles at the same time;

[0047] S2, uniformly mixing a part of the exterior wall paint and the tearing refill particles to obtain a mixture;

[0048] S3, evenly coating the mixture on the surface of the exterior wall, and forming a complete solid coating after drying;

[0049] S4, covering the grid cloth 2 on the surface of the above-mentioned solid coating, and then coating another...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com