Thrust bearing and air suspension centrifugal compressor

A technology of thrust bearings and bearing bushes, which is applied in the field of compressors, and can solve problems such as the reduction of gas film kinematic viscosity, small wedge angle, and reduction of bearing damping coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

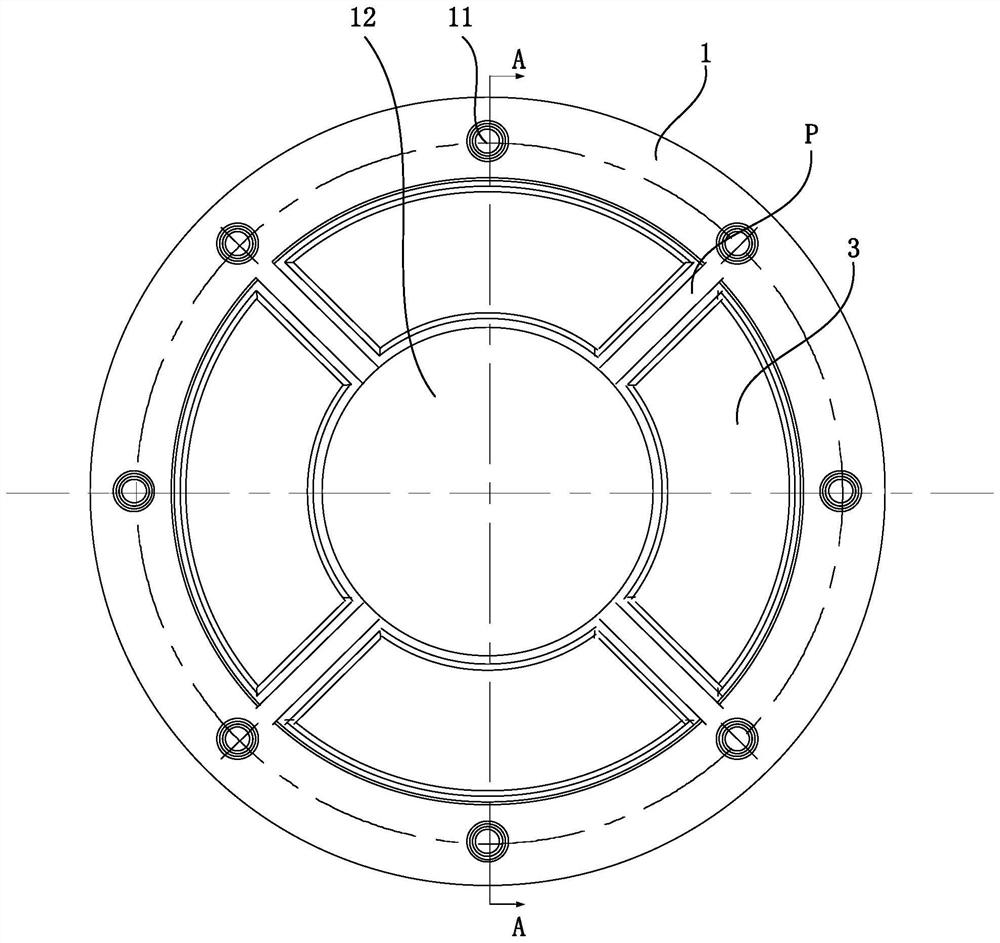

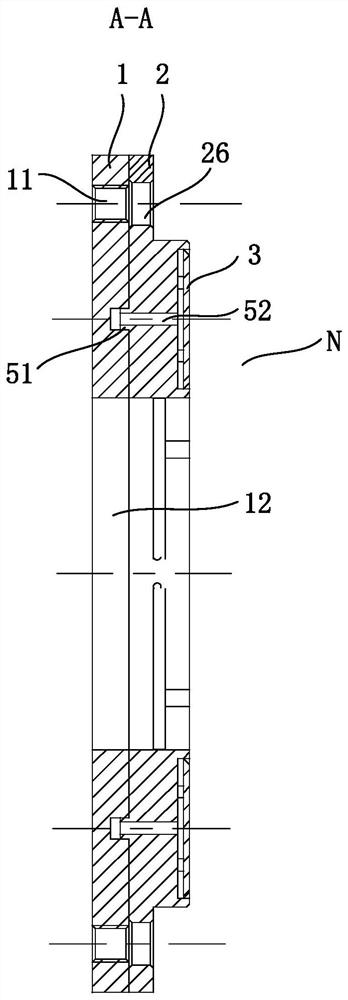

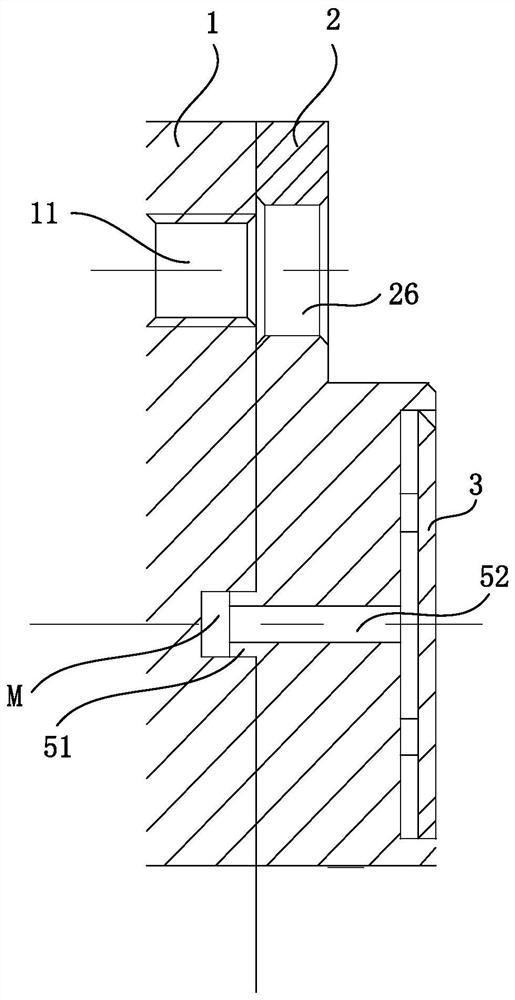

[0045] Combine below Figure 1 to Figure 12 The technical solution provided by the present invention is described in more detail.

[0046] An embodiment of the present invention provides a thrust bearing 10 , which includes a first seat 1 , a second seat 2 and a graphite piece 3 . The first seat body 1 includes a first through hole 12 . The second seat body 2 includes a base plate 21 fixedly connected with the first seat body 1 and a bearing bush 22 connected with the base plate 21 through a connection part 23; The joint of the bearing shell 22 moves. The graphite component 3 is mounted on the side of the bearing bush 22 away from the base plate 21 .

[0047] see Figure 1 to Figure 4 , the first seat body 1 is roughly disc-shaped, and a first through hole 12 is provided in the middle of the first seat body 1 , and the first through hole 12 is used for accommodating the end of the rotating shaft 6 .

[0048] see Figure 2a with Figure 2b Specifically, one side of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com