Hybrid transmission electro-hydraulic limp control oil way and method

A technology for controlling oil circuit and control method, which is applied in the direction of transmission control, components with teeth, belt/chain/gear, etc., and can solve the problems of complexity, long response time, and the inability of the transmission to limp.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

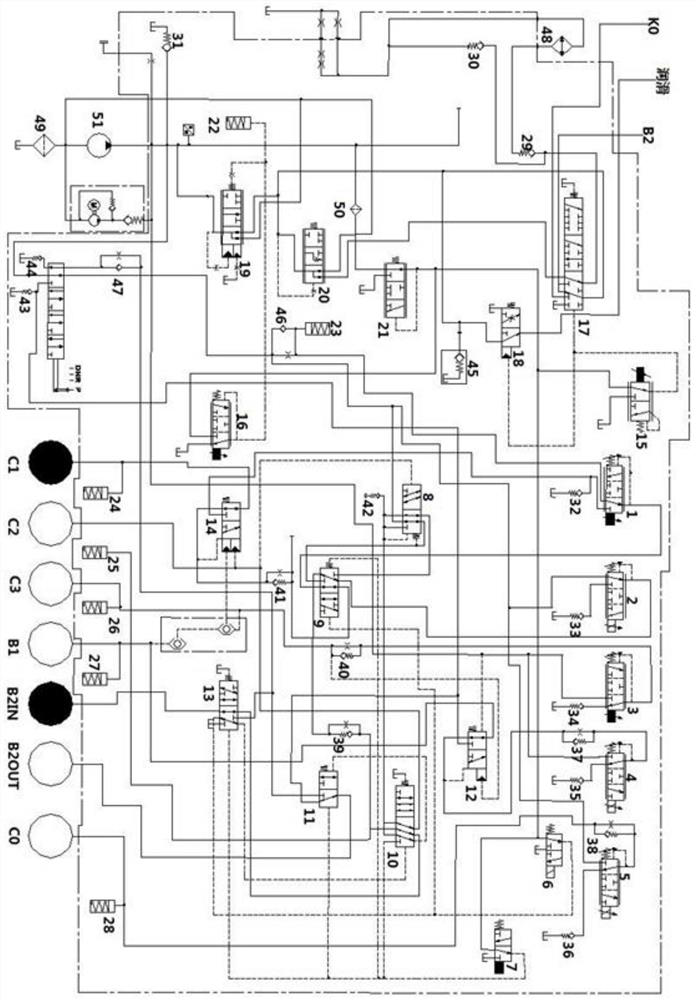

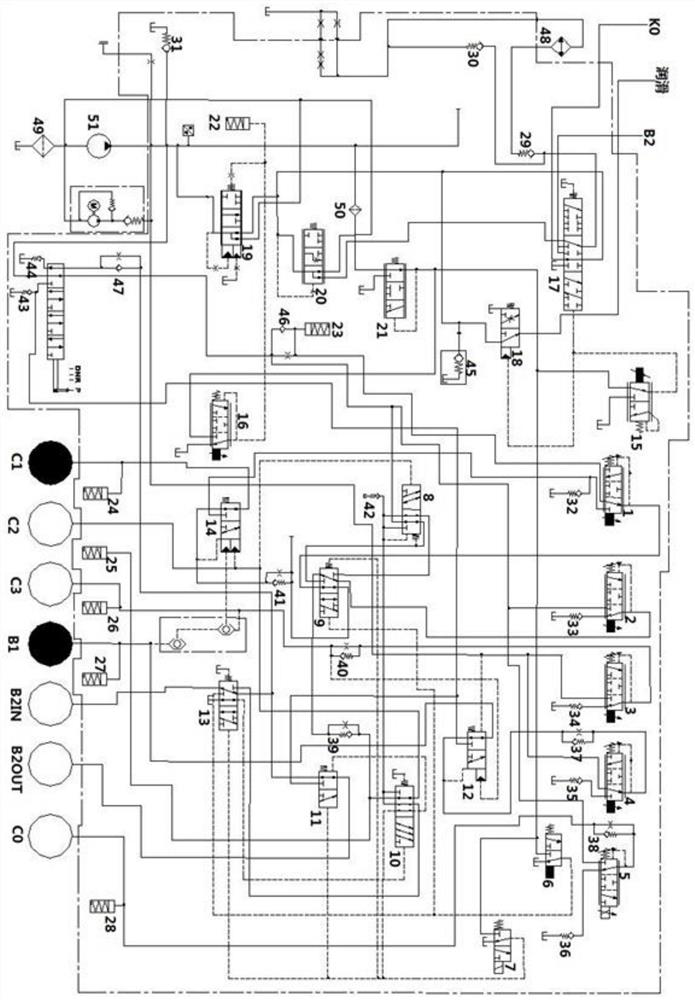

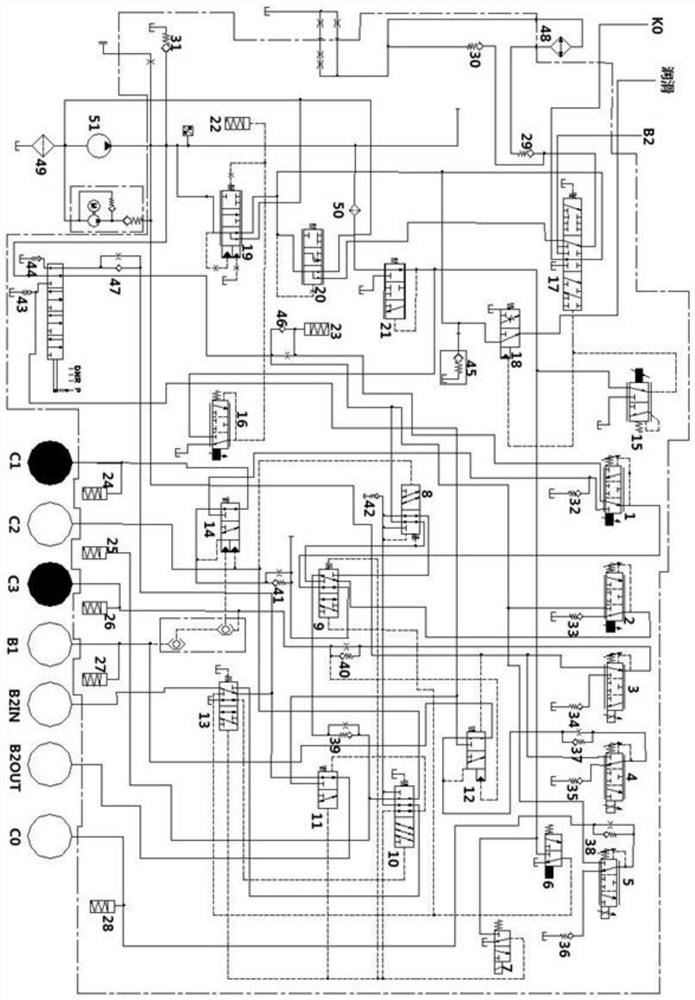

[0032] The invention will be further described in detail below with reference to the accompanying drawings:

[0033] Such as figure 1 As shown, for the hybrid transmission of the mixed transmission of the mixed transmission, including five electromagnetic commutation valves, four control electromagnetic replacement valves, twelve hydraulic replacement valves, seven accumulators, ten Nine one-way valves, an oil cooler, two oil filters, second oil filters and oil pumps.

[0034] The first electromagnetic commutation valve 1 and the second electromagnetic commutation valve 2, the fifth electromagnetic commutation valve 5, the second liquid exchange valve 9, the seventh liquid exchange valve 14, the second accumulator 23, the fourth single The valve 32 is connected to the 18th single-way valve 46.

[0035]The second electromagnetic commutation valve 2 is connected to the fifth electromagnetic commutation valve 5, the second hydraulic directional valve 9, the second accumulator 23, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com