Engine front end wheel train coplanarity detection device and calibration method

A front-end gear train and detection device technology, applied in measuring devices, optical devices, instruments, etc., can solve the problems of high production cost, long tooling processing time, complex structure, etc., to reduce difficulty, improve accuracy, and flexible detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

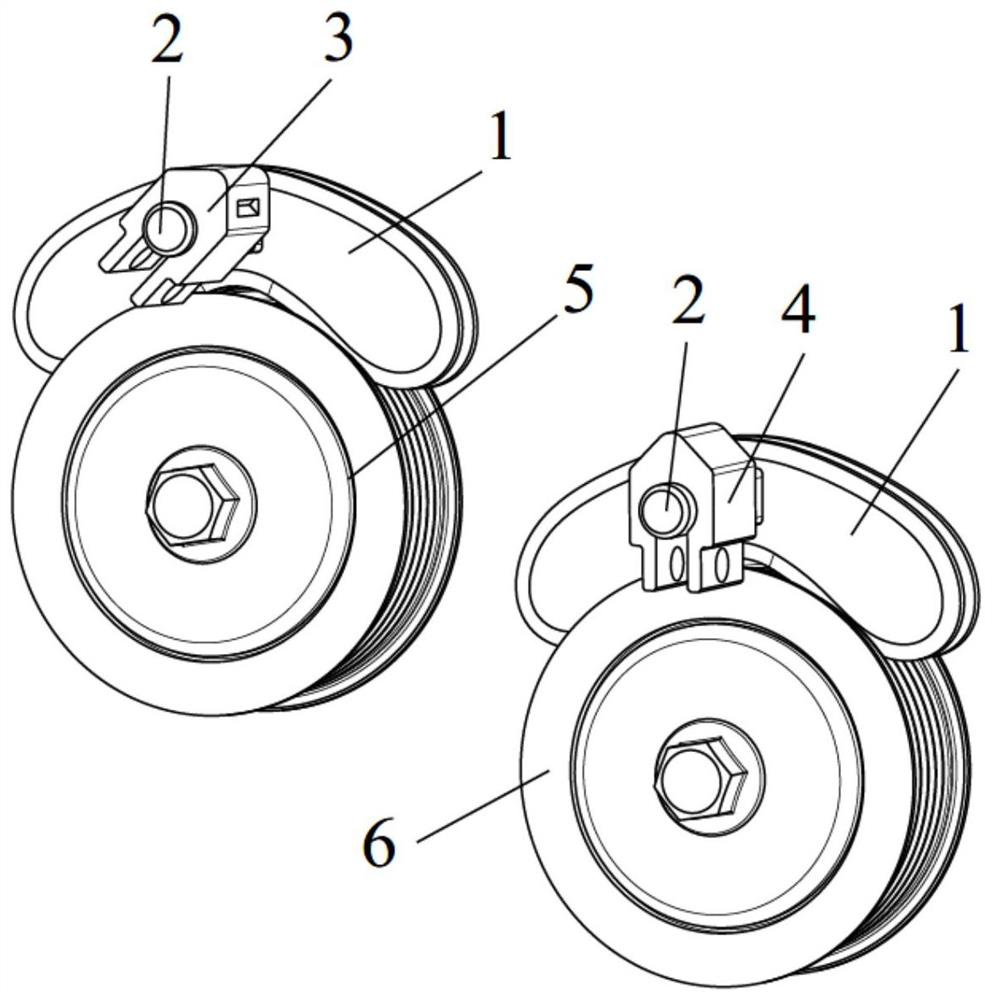

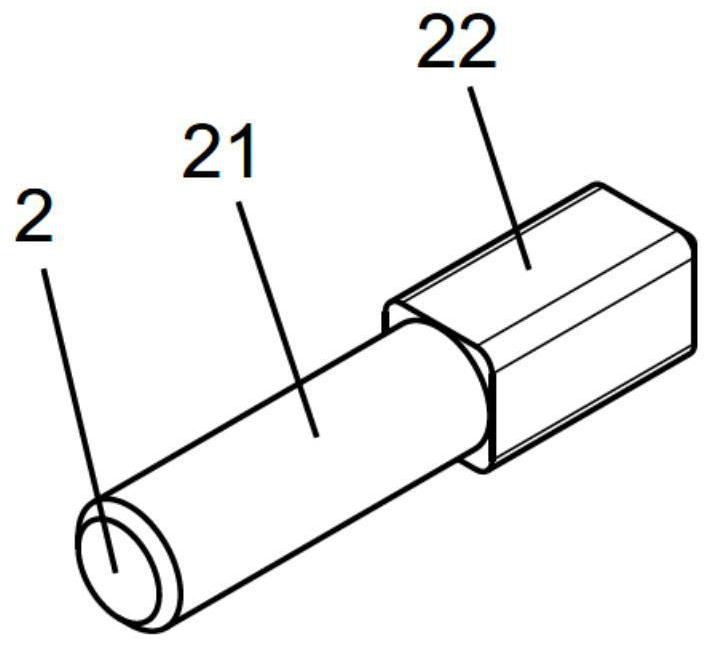

[0046] see figure 1 As shown, the present invention provides a coplanarity detection device for the front end of the engine train, which includes two sets of limit support units, two installation shafts 2 and a coplanarity corrector.

[0047]Each set of limit support units includes at least two limit support 1 parallel to each other, and each limit support 1 is provided with a wedge-shaped tooth that matches the wedge groove on the wedge wheel, and each set of limit support Different limit supports in the position support unit cooperate with different wedge grooves on the wedge wheel, and the wedge shape o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com