Method for predicting multi-axis constant-amplitude thermal mechanical fatigue life of notched part based on Kf method

A technology for thermo-mechanical fatigue and life prediction, which is applied in the directions of using a stable torsional force to test the material strength, using a stable shear force to test the material strength, and using a repetitive force/pulse force to test the material strength, etc. It can solve the problem of notched parts. The influence of fatigue life is different, etc., to achieve the effect of simple calculation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The specific embodiments of the present invention will be described with reference to the accompanying drawings.

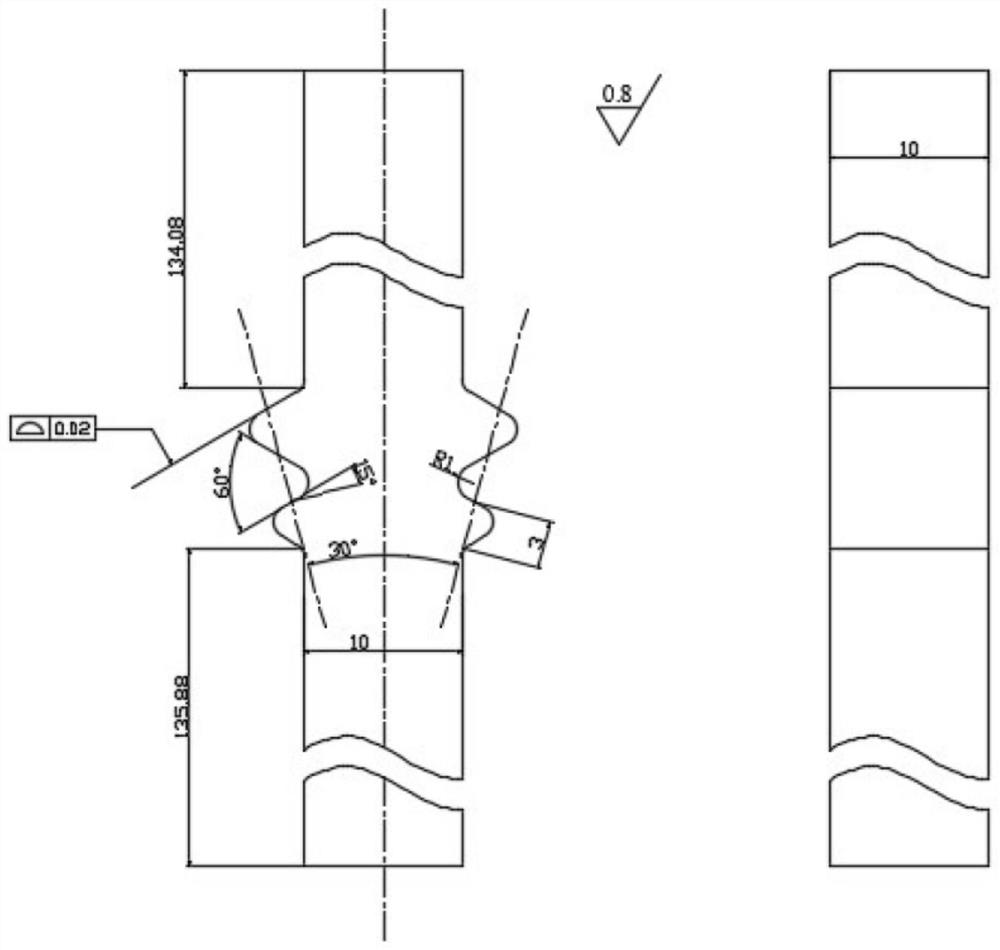

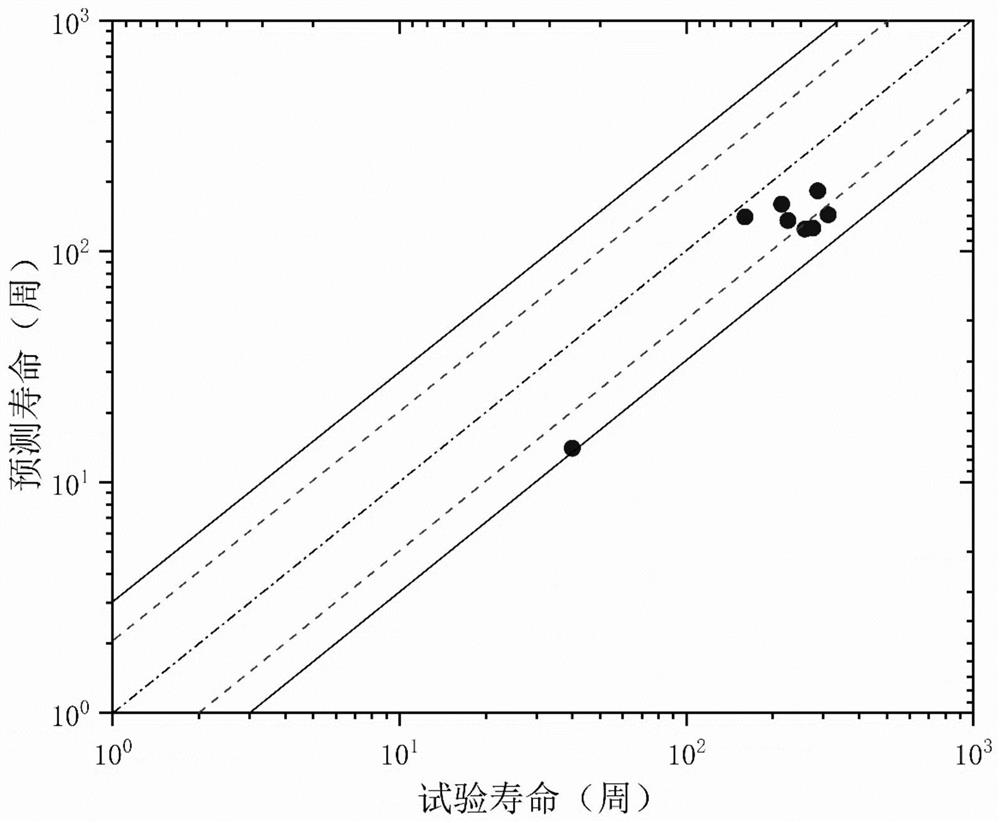

[0067] The invention is further illustrated by the axial torsion constant amplitude thermomechanical fatigue test of notched parts, the test material is nickel-based superalloy GH4169, the test temperature is 360-650°C, the test adopts stress loading, and the loading waveform is triangular wave.

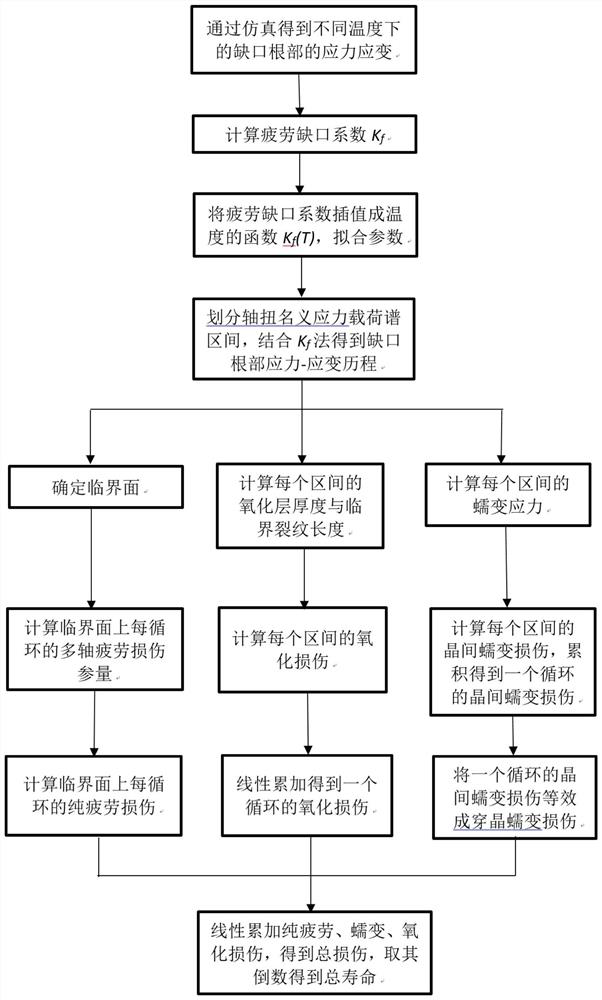

[0068] A method for predicting multi-axis constant-amplitude thermo-mechanical fatigue life of notched parts based on the Kf method, the specific embodiments are as follows:

[0069] Step (1): In the finite element simulation software, multiple groups of isothermal constant-amplitude axial torsion proportional loading are performed on the notched parts. The load spectrum is stress-controlled and the same, and each group has a different set temperature. The axial and torsional stress and strain of the root of the notched part under different temperature load condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com