Bed load grading determination method and device, storage medium and electronic equipment

A determination method and bedrock technology, applied in electrical digital data processing, computer-aided design, design optimization/simulation, etc., can solve problems such as inability to test river section simulation and inability to ensure the accuracy of bedrock gradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

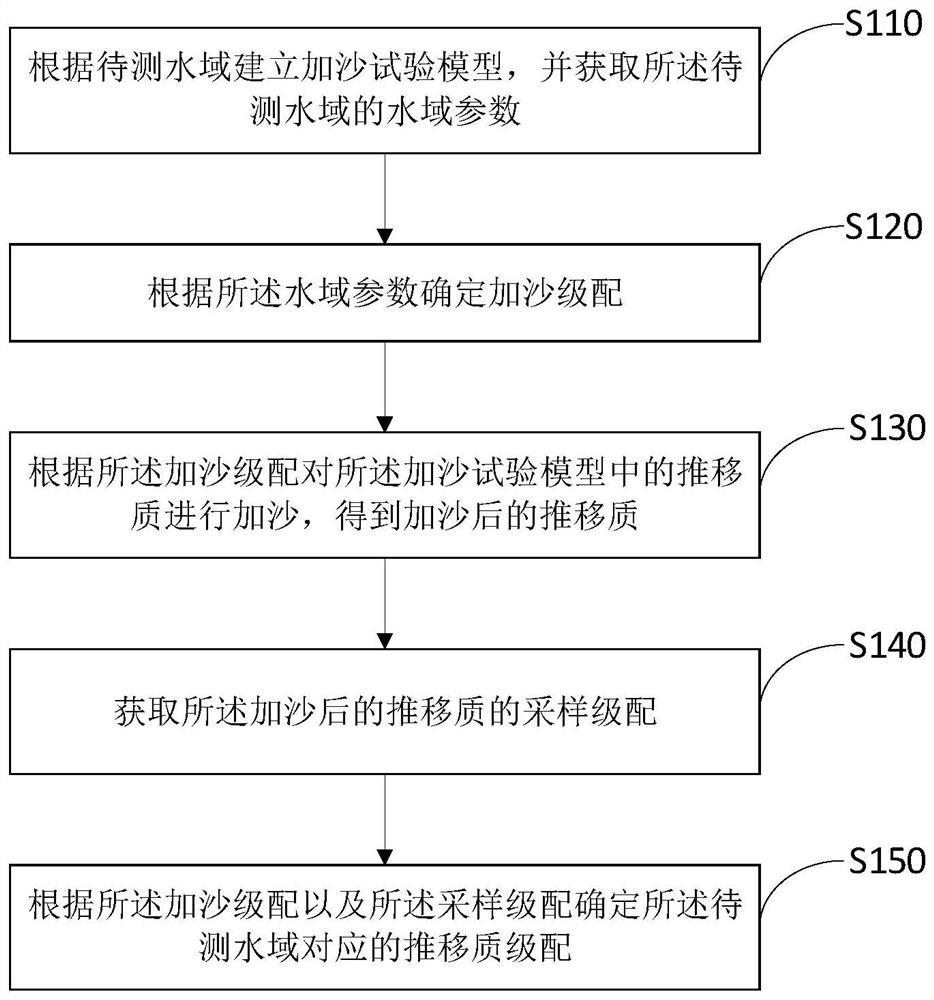

[0061] The present invention provides a method for determining mass gradation, please refer to figure 1 , the method includes the following steps:

[0062] Step S110: Establish a Gaza test model according to the water area to be tested, and obtain water area parameters of the water area to be tested.

[0063] When studying the water area to be measured, it is difficult to understand the change law of the water area to be measured by conventional methods, so the water area to be measured for the research object can be reduced to a model according to a certain proportion and characteristics. Depending on the research content and requirements, the model can be made into a fixed bed or a moving bed. The fixed bed river engineering model generally uses cement mortar to shape the shape of the river bed, which is suitable for studying the water surface line of the river, the change of the flow velocity and flow state, and the change of the branch channel. For issues such as diversio...

Embodiment 2

[0076] On the basis of the first embodiment, this embodiment describes the method in the first embodiment through specific implementation cases.

[0077] The methods for determining mass gradation include:

[0078] Establish the Gaza test model according to the water area to be tested, and obtain the water parameters of the water area to be tested;

[0079] Determination of Gaza grading based on said waters parameters;

[0080] According to the Gaza grading, the mass in the Gaza test model is added to obtain the mass after Gaza;

[0081] Obtain a sampling gradation of the post-Gaza mass;

[0082] According to the Gaza gradation and the sampling gradation, the mass gradation corresponding to the water area to be tested is determined.

[0083] Wherein, the Gaza gradation is calculated using the average particle size method and the water parameters, including:

[0084] Calculate the average particle size according to the water parameters and the average particle size calculat...

Embodiment 3

[0092]On the basis of the first embodiment, this embodiment describes the method in the first embodiment through specific implementation cases.

[0093] The methods for determining mass gradation include:

[0094] Establish the Gaza test model according to the water area to be tested, and obtain the water parameters of the water area to be tested;

[0095] Determination of Gaza grading based on said waters parameters;

[0096] According to the Gaza grading, the mass in the Gaza test model is added to obtain the mass after Gaza;

[0097] Obtain a sampling gradation of the post-Gaza mass;

[0098] According to the Gaza gradation and the sampling gradation, the mass gradation corresponding to the water area to be tested is determined.

[0099] Wherein, according to the Gaza grading and the sampling grading, determining the mass grading corresponding to the water area to be tested includes:

[0100] judging whether the absolute value of the difference between the Gaza gradatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com