Manufacturing and processing method of copper-aluminum wiring terminal

A copper-aluminum terminal block and processing method technology, which is applied in the manufacture of contacts, etc., can solve the problems that the terminal cannot be automatically lowered and fixed, multiple terminals cannot be punched in batches, and production and processing are inconvenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

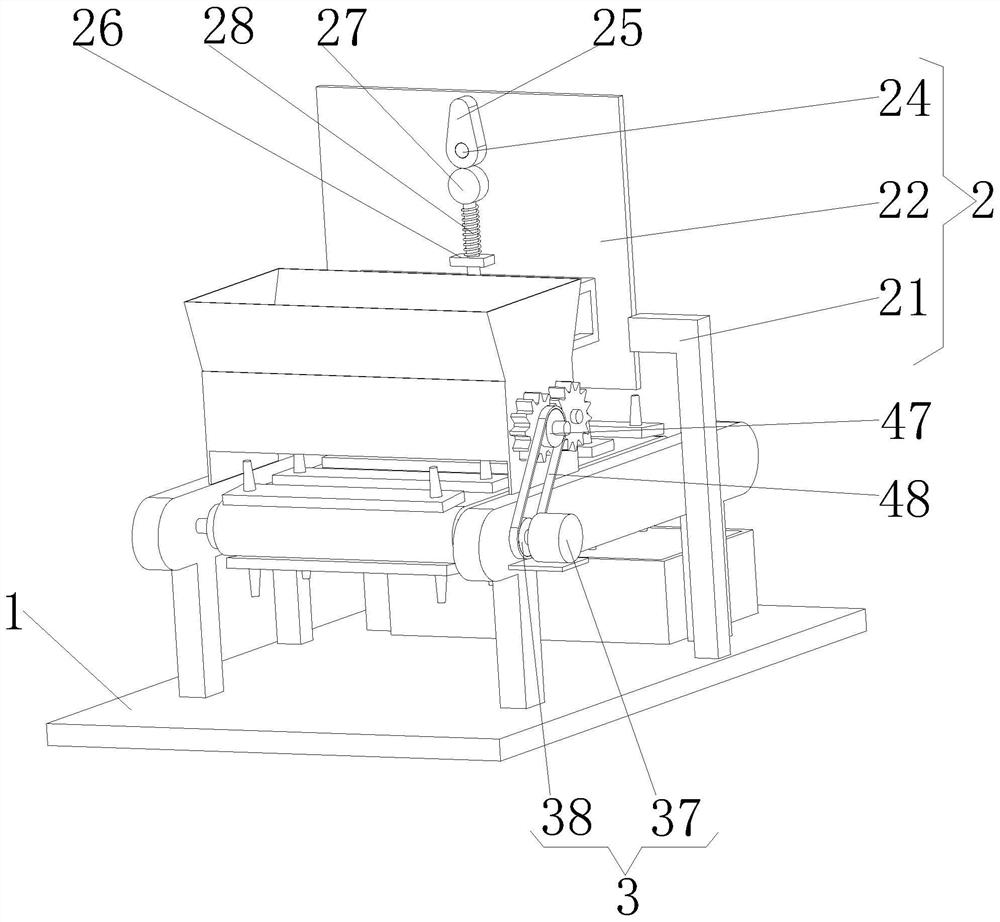

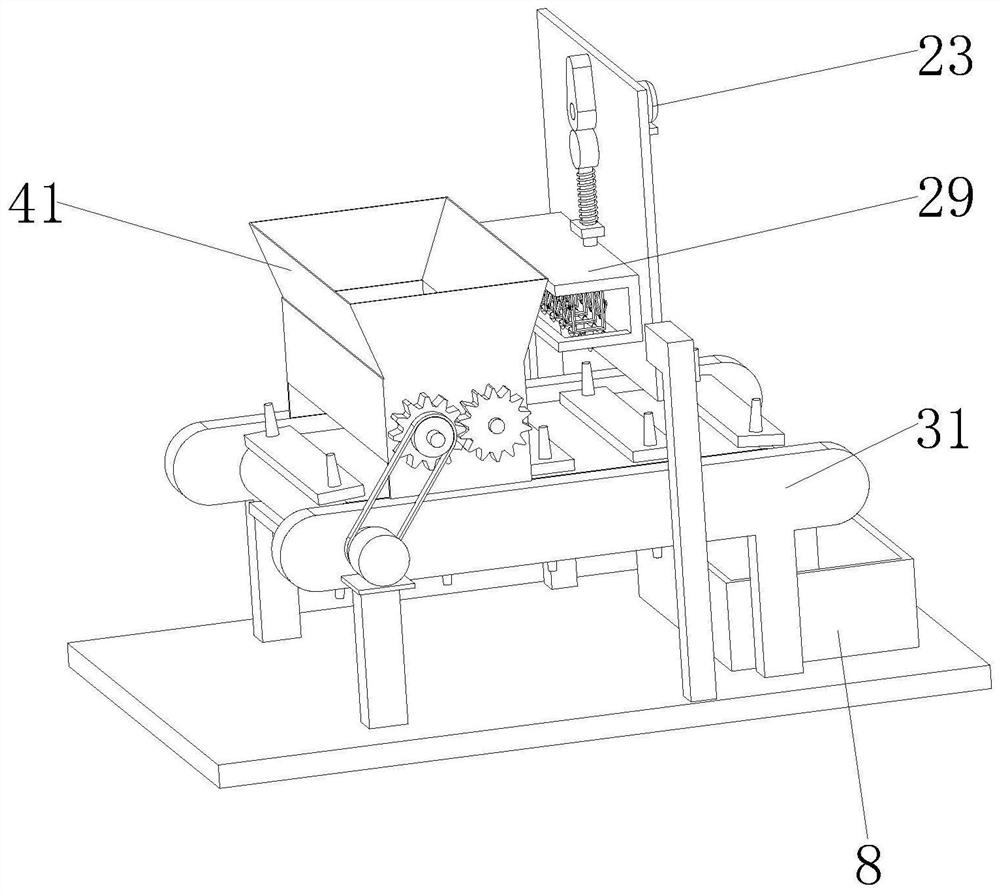

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

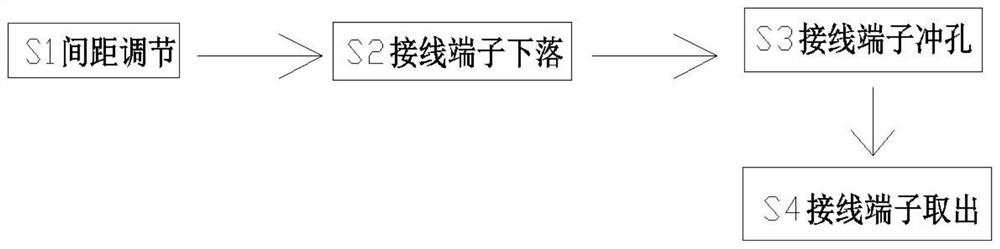

[0037] like Figure 1 to Figure 10 As shown, a copper-aluminum terminal manufacturing method, which uses a batch punching equipment, the batch punching equipment includes a base 1, punching device 2, conveying device 3, automatic feeding device 4, using the above batch The method for manufacturing and processing copper and aluminum terminals by punching equipment includes the following steps:

[0038] S1. Spacing adjustment: Pull the telescopic frame 56, and when the telescopic frame 56 is pulled, it drives the outer cylinder 57 below each connecting frame 55 to move, and when each outer cylinder 57 moves, it drives the punching knife 592 below each outer cylinder 57 to move, thereby Realize the synchronous adjustment of each punching knife 592, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com