Separated liquid cooling system for phase change heat transfer module of data center and control method of separated liquid cooling system

A data center, separate technology, used in the use of liquid cooling for modification, cooling/ventilation/heating retrofit, electrical components, etc., can solve the problems that plague data centers, high costs, coolant leakage, etc., and reduce coolant leakage. risk, and the effect of improving the convenience of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

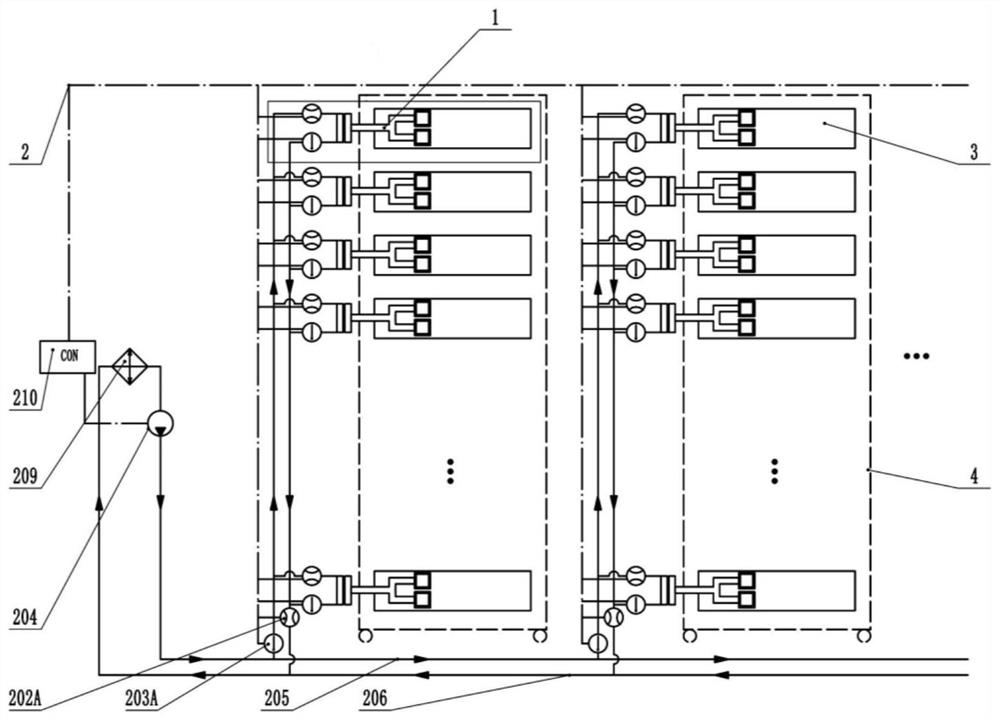

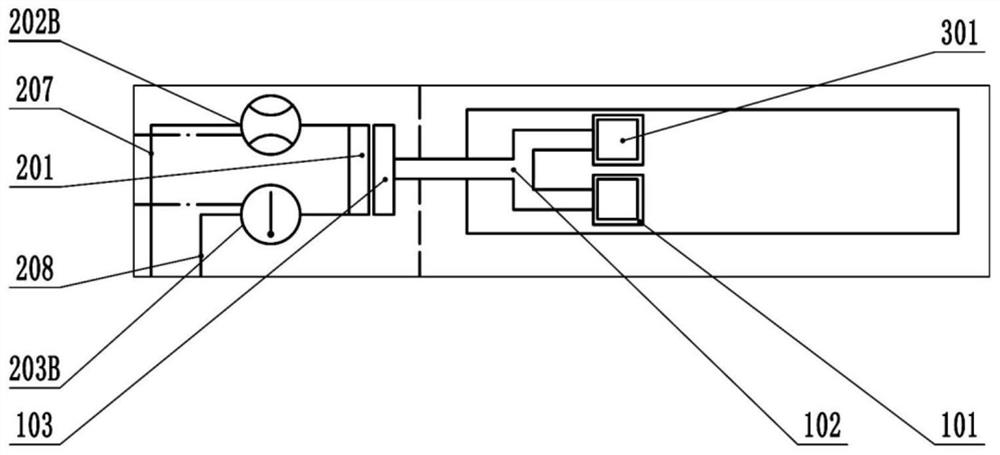

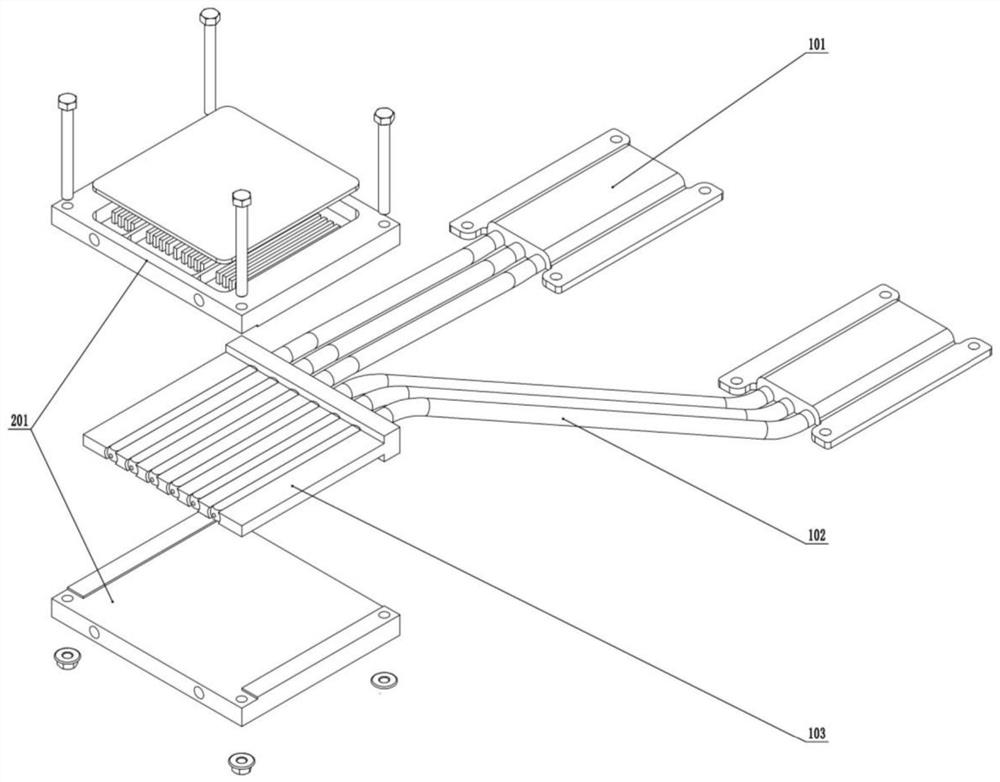

[0019] like Figure 1a and 1b As shown, it is a schematic diagram of a phase change heat transfer module separated liquid cooling system in a data center, including a phase change heat transfer module 1 and an external circulation heat exchange system 2; the phase change heat transfer module 1 is installed in a server 3, It is used to collect the heat generated by the internal processor of the server and transfer the collected heat to the heat conduction plate outside the cabinet; the external circulation heat exchange system is connected with multiple cabinets 4 in parallel to take away the heat on the heat conduction plate and discharge it into the Atmospheric environment and real-time monitoring system operation.

[0020] The external circulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com