Cheese milk cover pulp and preparation method thereof

A cheese and milk technology, applied in milk preparations, dairy products, tea extraction, etc., can solve the problems of affecting product taste and flavor release, affecting milk capping effect, destroying stable structure, etc., to improve product taste and flavor release , Improve the convenience of terminal use, the effect of strong cheese flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation of embodiment 1 cheese milk cover slurry (10kg)

[0048] 1. Preparation of cheese milk paste (10kg)

[0049]1) Mixing: Heat 20% milk to 50°C, add 0.10% Tween 60 and 0.06% guar gum, stir for 8 minutes, add 19.74% condensed milk, 0.10% edible salt and 15% cream cheese, and stir under high shear until the cheese is dissolved to obtain the first mixture;

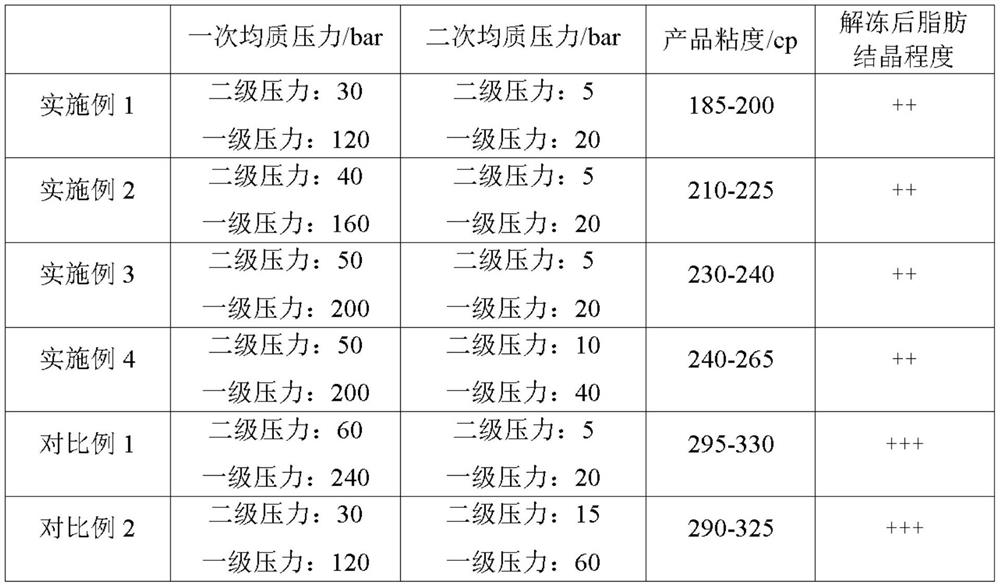

[0050] 2) Primary homogenization: the temperature of the first mixture is raised to 70°C for homogenization, the pressure of the secondary homogenization is 30 bar, and the pressure of the primary homogenization is 120 bar;

[0051] 3) Secondary homogenization: add 45% whipped cream to the first mixture to obtain the second mixture, raise the temperature to 80°C, and perform homogenization. The pressure of the second homogenization is 5 bar, and the pressure of the first homogenization is 20 bar;

[0052] 4) Pasteurization: pasteurize the second mixture at a sterilization temperature of 95° C. and a ster...

Embodiment 2

[0054] The preparation of embodiment 2 cheese milk cover slurry (10kg)

[0055] The preparation process is the same as that in Example 1, except that in the first homogenization step, the pressure of the second homogenization is 40 bar, and the pressure of the first homogenization is 160 bar.

Embodiment 3

[0056] The preparation of embodiment 3 cheese milk cover slurry (10kg)

[0057] The preparation process is the same as that in Example 1, except that in the first homogenization step, the pressure of the second homogenization is 50 bar, and the pressure of the first homogenization is 200 bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com