Cheddar fermented milk and making method thereof

A technology of fermented milk and cheese, applied in buttermilk, dairy products, applications, etc., can solve the problems of natural cheese powder being difficult to dissolve and not like, and achieve the effect of strong cheese flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention provides a kind of preparation method that adds the fermented dairy product of cheddar (cheddar cheese), it comprises the following steps:

[0027] The raw materials of the cheddar (cheddar cheese) fermented milk include: milk 90.919-92.55%, sucrose 7-8%, cheddar cheese powder 0.2-0.7%, polyphosphate and citrate mixture, or polyphosphate and mono 0.15-0.38% of the phosphate mixture, 0.001-0.1% of the leavening agent, and the percentages mentioned are the mass percentages of the total mass of raw materials;

[0028] Step 1) is: heating 30-50% of the total amount of milk to 70-80° C., adding cheddar cheese powder and mixed salt, and stirring for 15-25 minutes to obtain material A.

[0029] Step 2) is: homogenize the material A through 20-25MPa;

[0030] Step 3) is: raise the temperature of the remaining milk to 40-50°C, add the homogenized material A and sucrose, heat and stir for 10-20 minutes, this is material B;

[0031] Step 4) is: raising the ...

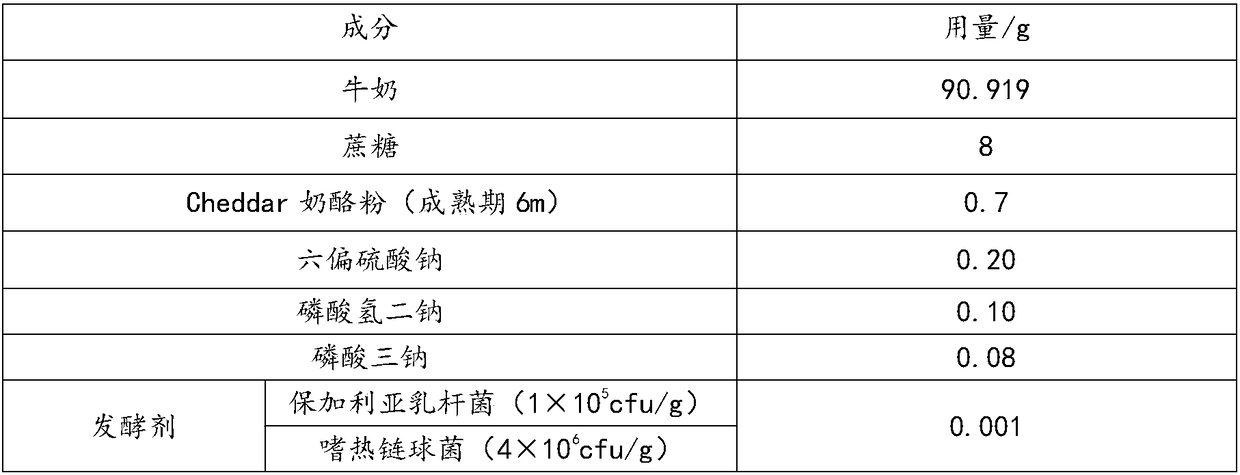

Embodiment 1

[0047] formula:

[0048]

[0049] The process steps are as follows:

[0050] 1. Heat 50% of the total amount of milk to 80°C, add natural cheddar cheese powder and mixed salt, keep stirring for 25 minutes, and obtain material A;

[0051] 2. Raise the temperature of material A to 65°C and homogenize at 25MPa;

[0052] 3. Raise the temperature of the remaining milk to 50°C, add the homogenized material A and sucrose, keep stirring for 20 minutes, this is material B;

[0053] 4. Raise the temperature of material B to 65°C and homogenize at 22MPa;

[0054] 5. Sterilize the homogenized material B at 85°C for 15 minutes, cool to 35°C, and add starter to ferment;

[0055] 6. When the fermentation reaches a titrated acidity of 90°T, the material is turned over to cool down, filled, and refrigerated.

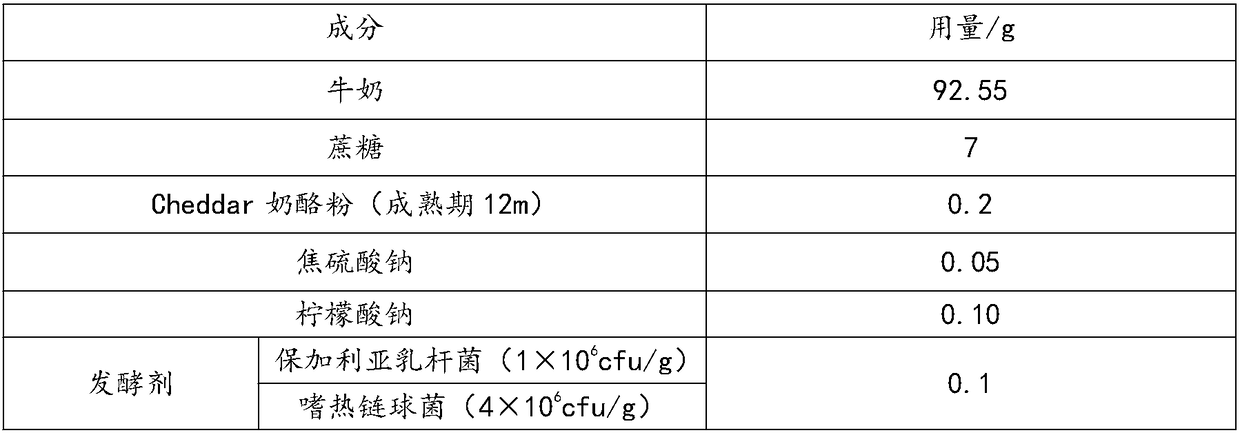

Embodiment 2

[0057] formula:

[0058]

[0059] The process steps are as follows:

[0060] 1. Heat 30% of the total amount of milk to 70°C, add natural cheese powder and mixed salt, keep stirring for 15 minutes, and obtain material A;

[0061] 2. Raise the temperature of material A to 60°C and homogenize at 20MPa;

[0062] 3. Heat the remaining milk to 40°C, add the homogenized material A and sucrose, keep stirring for 10 min, this is material B;

[0063] 4. Raise the temperature of material B to 60°C and homogenize under 18MPa;

[0064] 5. Sterilize the homogenized material B at 85°C for 15 minutes, cool to 42°C, and add starter to ferment;

[0065] 6. When the fermentation reaches a titrated acidity of 70°T, the material is turned over to cool down, filled, and refrigerated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com