Drum-type biochemical decomposition stirrer

A biochemical decomposition, drum-type technology, applied in mechanical equipment, engine components, engine sealing, etc., can solve the problems of long shaft length, capacity restriction, difficult processing, etc., to reduce the installation length, increase the processing capacity, and improve the bearing capacity. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is further described in detail through specific implementation methods:

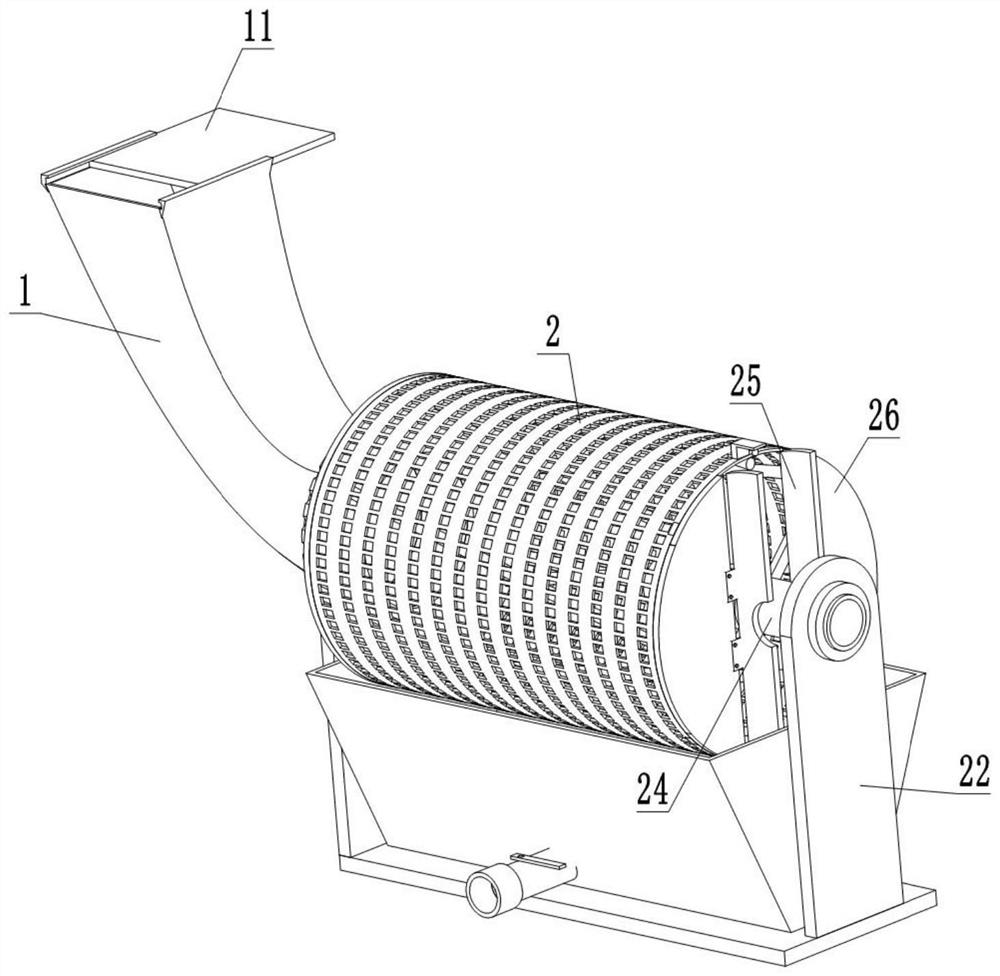

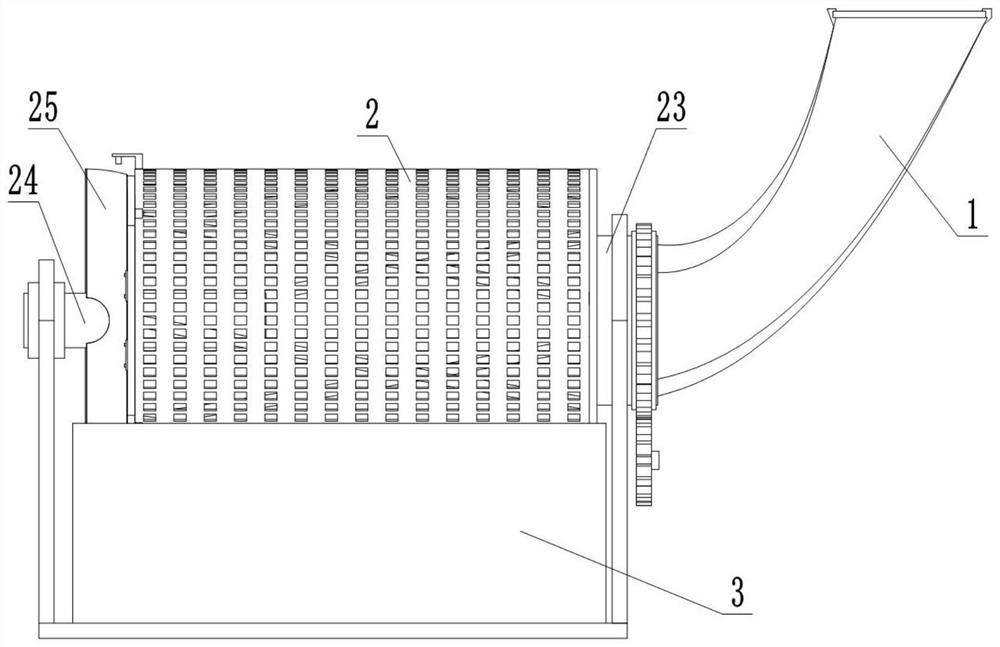

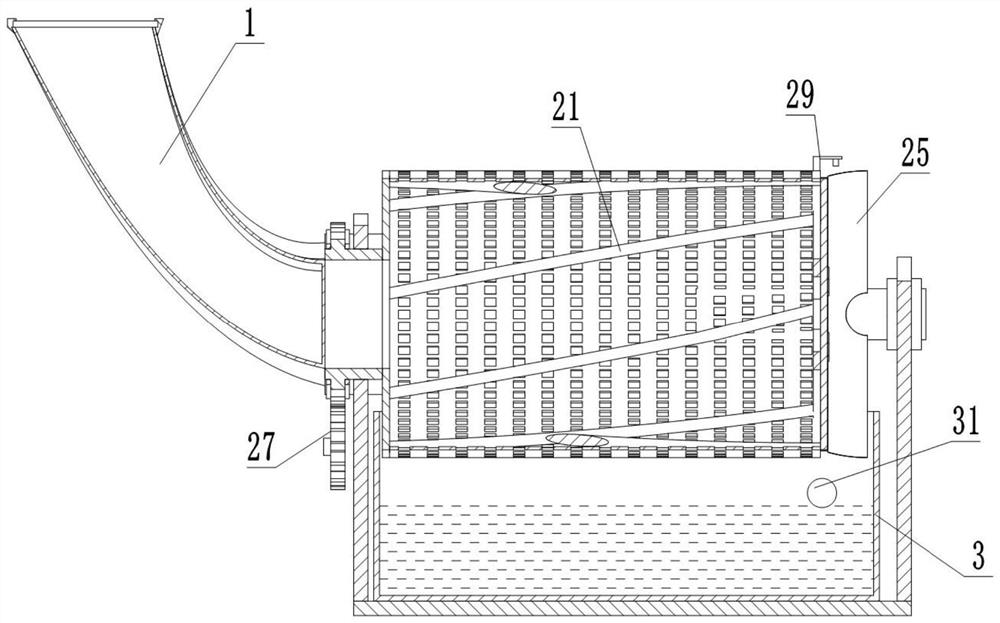

[0028] Such as figure 1 with figure 2 As shown, the drum 2 type biochemical mixer mainly consists of 4 parts, which are the feeding mechanism, the stirring mechanism, the decomposition liquid collection mechanism and the control system for controlling the coordinated work of each part. The feeding mechanism is connected to one end of the stirring mechanism. Its purpose is to transport kitchen waste to the inside of the mixing mechanism. The decomposition liquid collection mechanism is installed under the mixing mechanism. Its purpose is to collect the liquid produced by the fermentation of kitchen waste in the mixing mechanism. In this embodiment, it is installed in a separate closed space with controllable air flow, and one end of the feeding mechanism is located outside the closed space, which is convenient for feeding kitchen waste.

[0029] The feeding mechanism mainly include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com